Chain drive lubricating mechanism and bicycle

A technology of lubricating mechanism and chain transmission, applied in bicycle accessories, transmission parts, mechanical equipment, etc., can solve the problems of chain transmission prone to failure, damage, complicated lubrication operation, etc. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

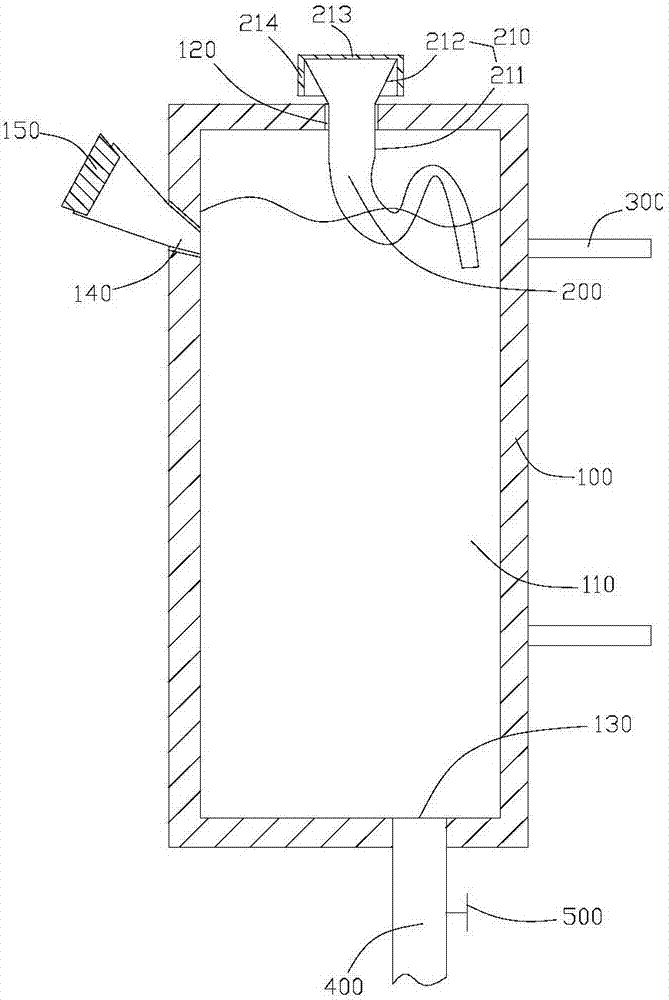

[0042] see figure 1 - image 3 , This embodiment provides a chain transmission lubricating mechanism, which is used to be installed on a bicycle to realize the lubrication of the chain transmission mechanism of the bicycle.

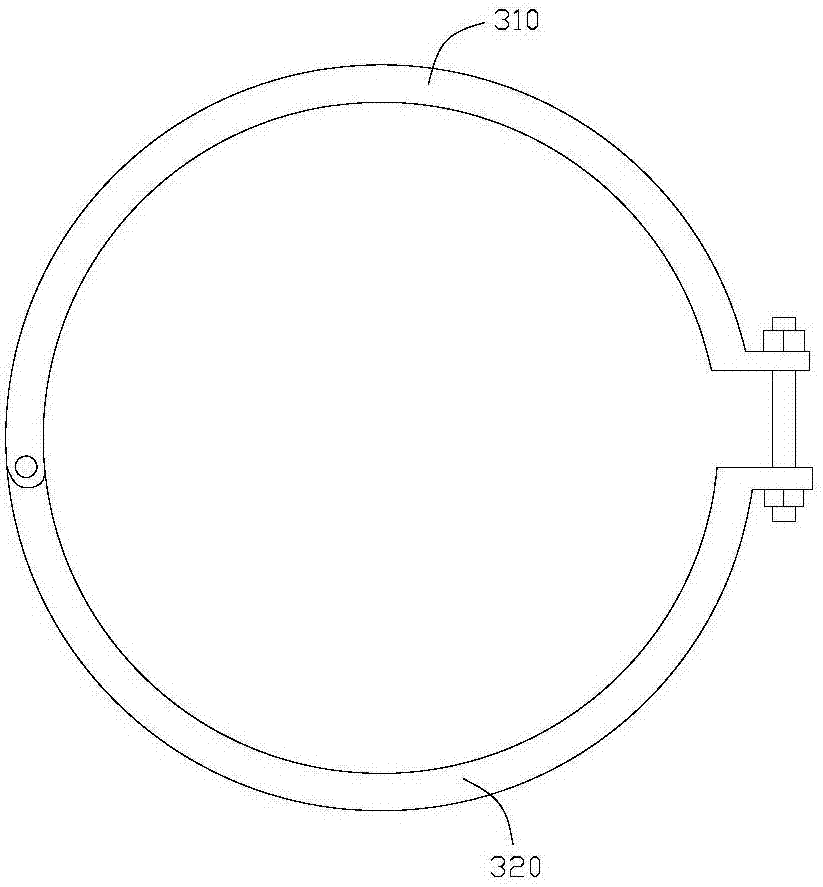

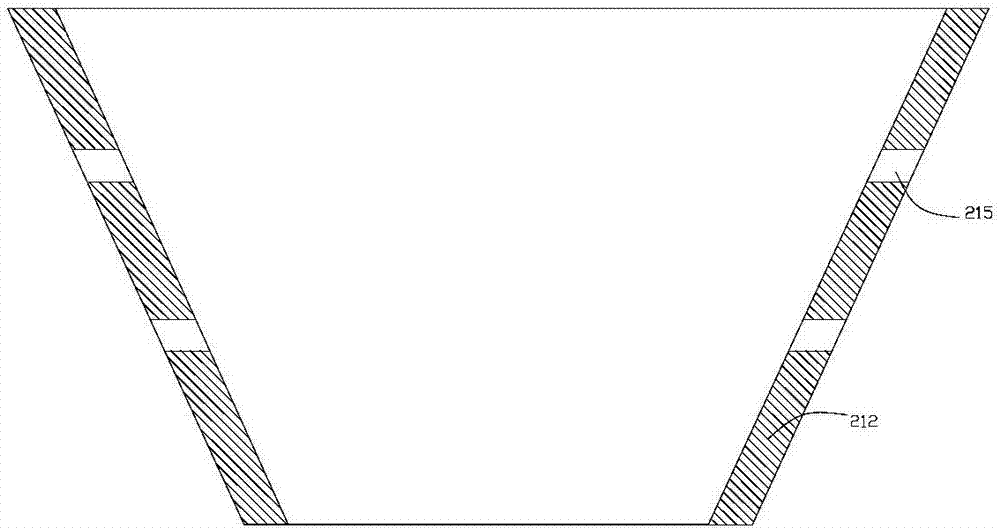

[0043] The chain drive lubricating mechanism provided in this embodiment includes an oil storage part 100, an overflow prevention part 200, a connecting part 300, an oil guide pipe 400 and a control switch 500. The oil storage part 100 has an oil storage chamber 110, and the oil storage chamber 110 The air inlet 120 communicated with the oil storage chamber 110 and the oil outlet 130, and the anti-overflow member 200 is installed at the air inlet 120 to prevent the oil in the oil storage chamber 110 from overflowing from the air inlet 120, The connector 300 is used to install the oil storage part 100 on the bicycle. One end of the oil guide pipe 400 communicates with the oil outlet 130. The oil guide pipe 400 can transport the oil in the oil storage cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com