Automatic rust removal vehicle for train rails

A train track and automatic technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of grinding machine noise, rail aging, and rust on both sides of rails, etc., to achieve high work efficiency, cost reduction, and thorough rust removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

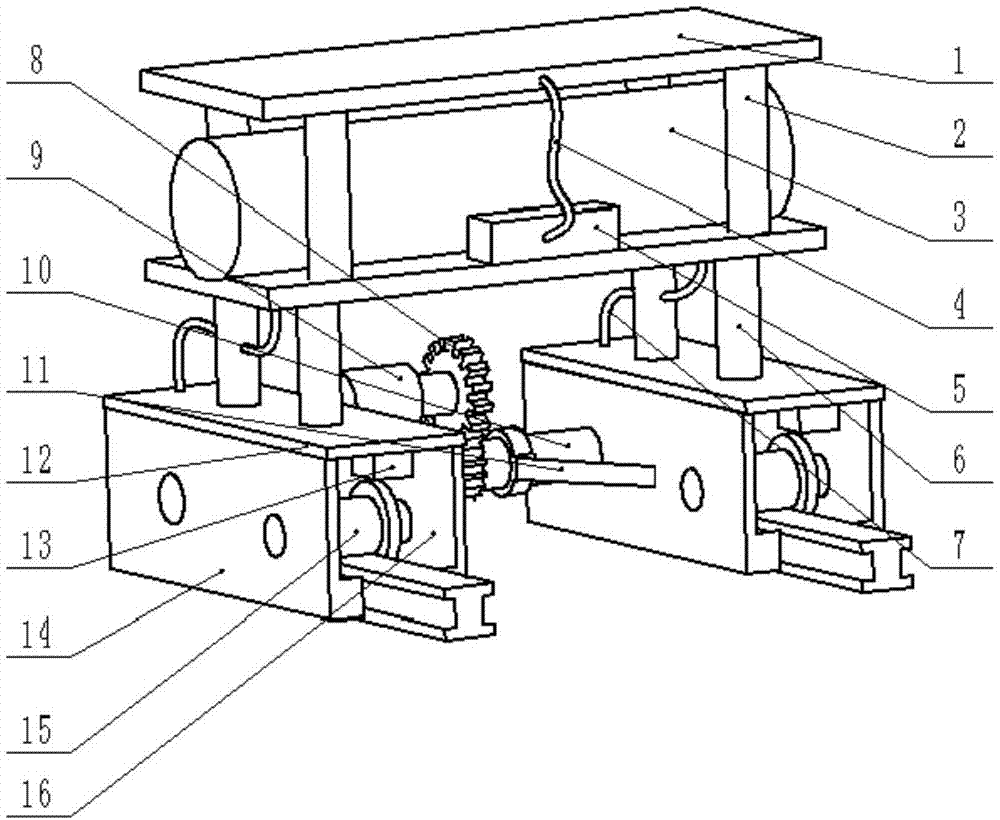

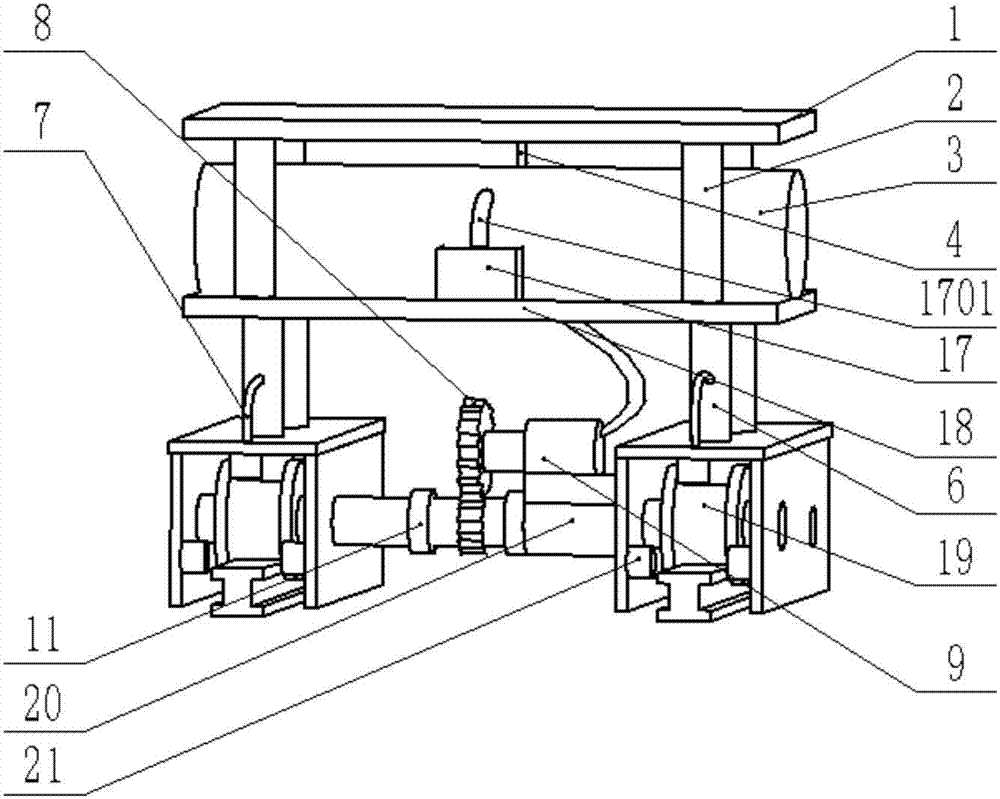

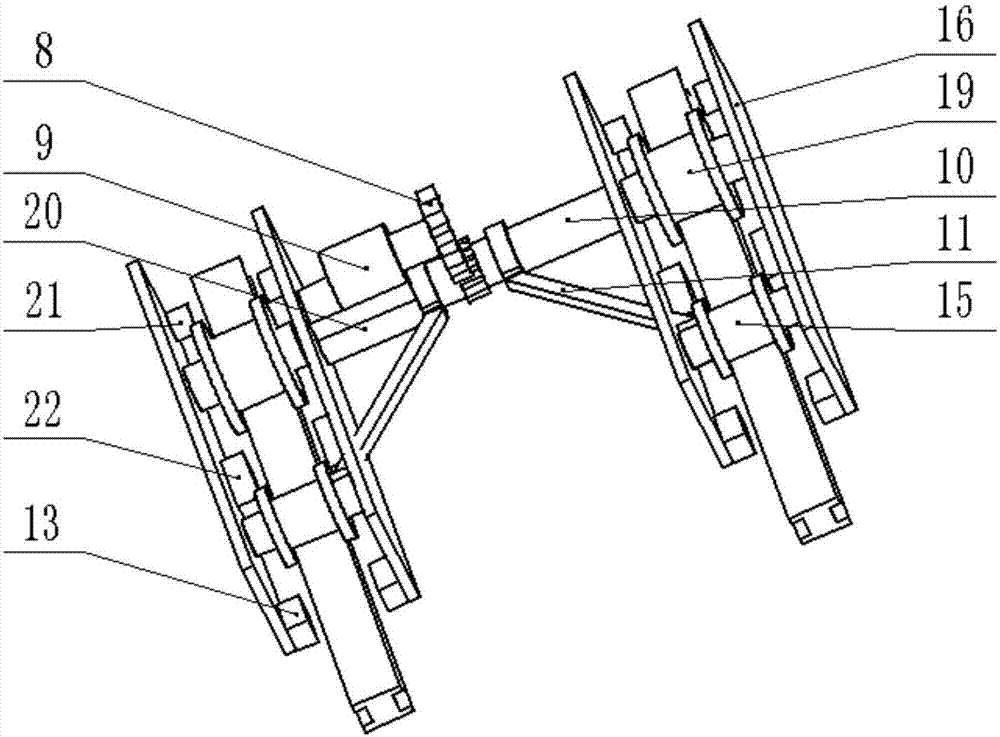

[0008] An automatic derusting car for train tracks is composed of a solar power generation panel 1, an upper pillar 2, a storage cylinder 3, a wire 4, a battery 5, a lower pillar 6, a hose 7, a gear 8, a motor 9, a transmission shaft 10, and a connecting rod 11. Driven wheel connecting sleeve 1101, transmission shaft connecting sleeve 1102, upper protective plate 12, laser rust remover 13, left protective plate 14, driven wheel 15, right protective plate 16, supercharger 17, connecting pipe 1701, support plate 18. The driving wheel 19, the wheel shoulder 1901, the transmission shaft hole 1902, the motor mounting bracket 20, the shaft sleeve 2001, the upper mounting groove 2002, the atomizing nozzle 21 and the ultrasonic descaling machine 22 are characterized in that: the sun The power generation board 1 is in the shape of a cuboid as a whole, and is installed above the upper pillar 2, at the top of the entire derusting vehicle; the upper pillar 2 is cylindrical in shape, locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com