Pressure-relief gas drainage top caving coal mining method for extremely thick hard coal seam

A coal mining method and top coal caving technology, which is applied in the directions of gas emission, surface mining, mining equipment, etc., can solve the problems of large production impact of working face, defective anti-reflection technology and process method, unsatisfactory effect, etc. High efficiency, intrinsic safety, and the effect of safe mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

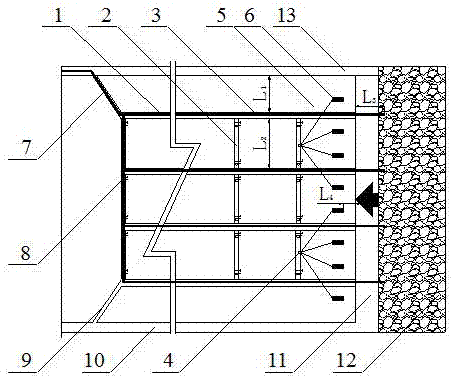

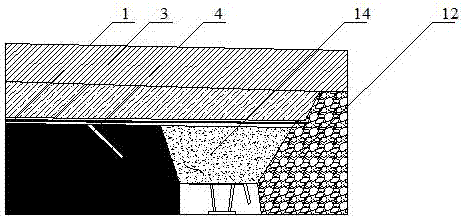

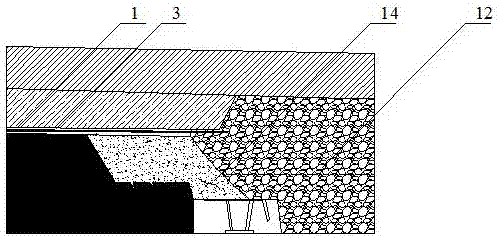

[0021] Such as Figure 1-3 As shown, the top-coal caving face 11 is arranged along the bottom of the extremely thick and hard coal seam, and the lower lane 9 and the upper lane 7 are arranged obliquely from the transportation lane 10 of the top-coal caving face and the return air lane 13 of the top-coal working face to reach the extremely thick and hard coal seam. At the top of the hard coal seam, a group of high-level process lanes 1 arranged in parallel are excavated at intervals along the top of the huge-thick hard coal seam. The high-level process lanes 1 are connected by a group of connecting lanes 2 arranged in parallel at intervals. For ventilation, the high-level gas drainage pipe 3 is arranged in the high-level process lane 1, the drilling site 4 is arranged in the connecting lane 2, the drilling site 4 is used to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com