Parallel operation coal mining method of pressure relief gas drainage and top coal caving in huge thick and hard coal seam

A parallel operation and top-coal caving technology, which is applied in the direction of gas discharge, ground mining, mining equipment, etc., can solve problems such as defects in anti-reflection technology and process methods, unsatisfactory results, and large impact on working face production, etc., to achieve intrinsic safety , high production efficiency, and achieve the effect of safe mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

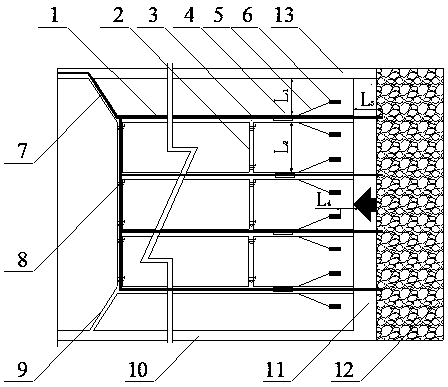

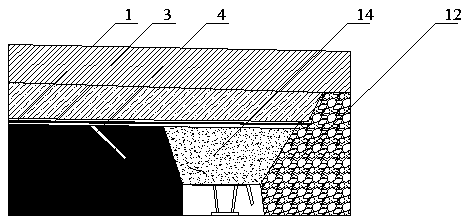

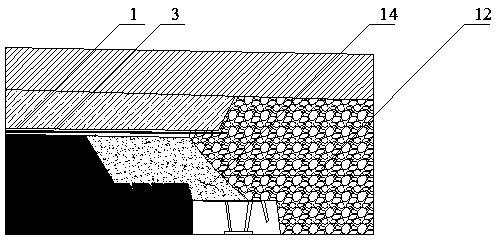

[0021] Such as Figure 1-3 As shown, the top-coal caving face 11 is arranged along the bottom of the extremely thick and hard coal seam, and the lower lane 9 and the upper lane 7 are arranged obliquely from the transportation lane 10 of the top-coal caving face and the return air lane 13 of the top-coal working face to reach the extremely thick and hard coal seam. On the top of the hard coal seam, a group of high-level process lanes 1 arranged in parallel are excavated at intervals along the top of the huge-thick hard coal seam. One high-level process lane is connected with a connecting lane 2, and the adjusting windshield 8 is set in the connecting lane 2 to control ventilation. In 1, the high-level gas drainage pipe 3 and the drilling site 4 are arranged, and the drilling site 4 is used to construct the drilling hole 5 downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com