Structure for ensuring concentricity of gas compressor control mechanism through rolling contact

A control mechanism and rolling contact technology, applied in the direction of machines/engines, liquid fuel engines, pumping devices for elastic fluids, etc., can solve the problems affecting the reliability of the engine control mechanism, poor follow-up of the adjustment system, and baffles wear and other problems, achieve huge economic and social benefits, reduce the frequency of replacement, and reduce the effect of long-term wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

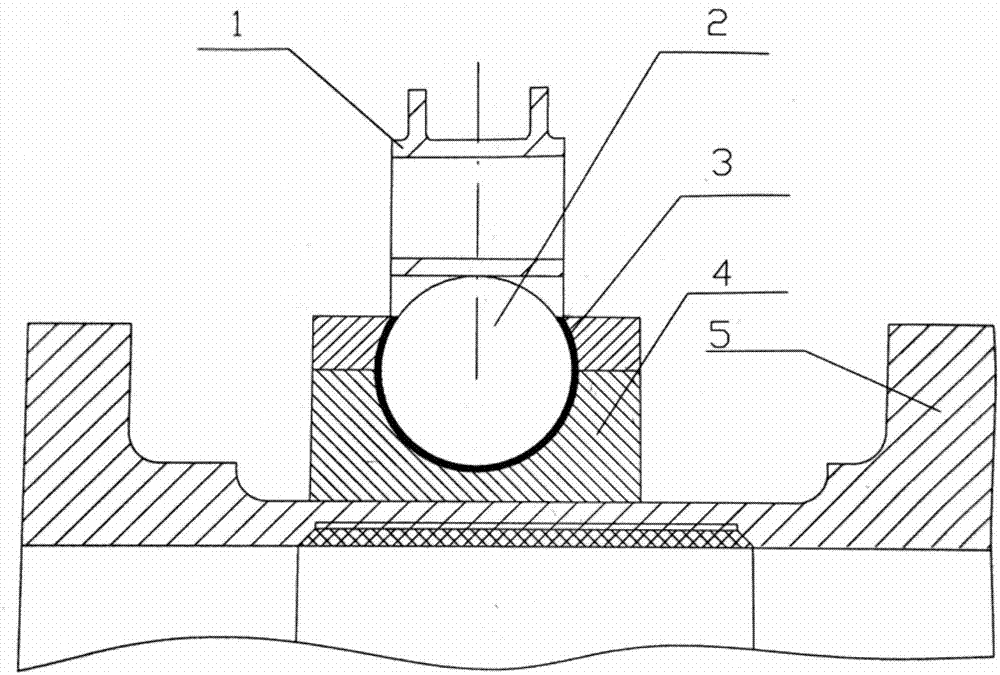

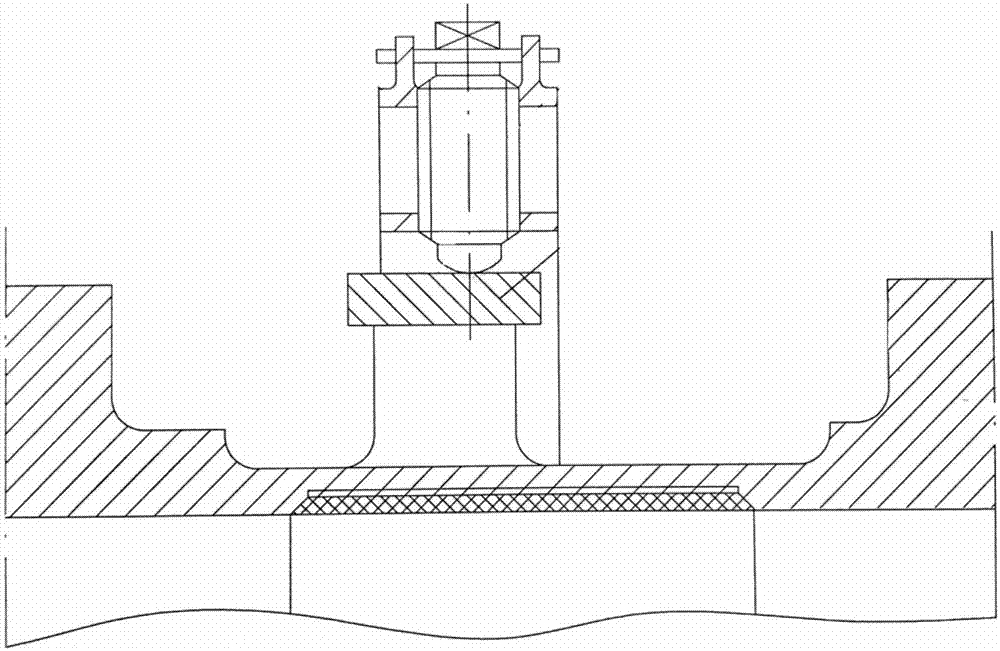

[0021] Such as Figure 1-2 Shown is a structure that uses rolling contact to ensure the concentricity of the compressor control mechanism, including actuating ring 1, ball 2, wear-resistant layer 3, ball seat 4 and casing 5;

[0022] The ball seat 4 is a cuboid structure;

[0023] The ball seat 4 is fixed on the casing by welding or bolting;

[0024] The ball seat 4 is provided with a ball and socket structure;

[0025] A wear-resistant layer 3 is provided in the ball-and-socket structure;

[0026] The ball 2 is placed in the ball seat 4;

[0027] The actuating ring 1 is in surface contact with the ball 2;

[0028] The actuating ring 1 and the casing 5 are arranged concentrically.

[0029] The ball 2 is spherical.

[0030] The wear-resistant layer 3 can be a ceramic layer or a non-metallic coating;

[0031] A plurality of ball seats 4 and balls 2 are evenly distributed on the casing 1 .

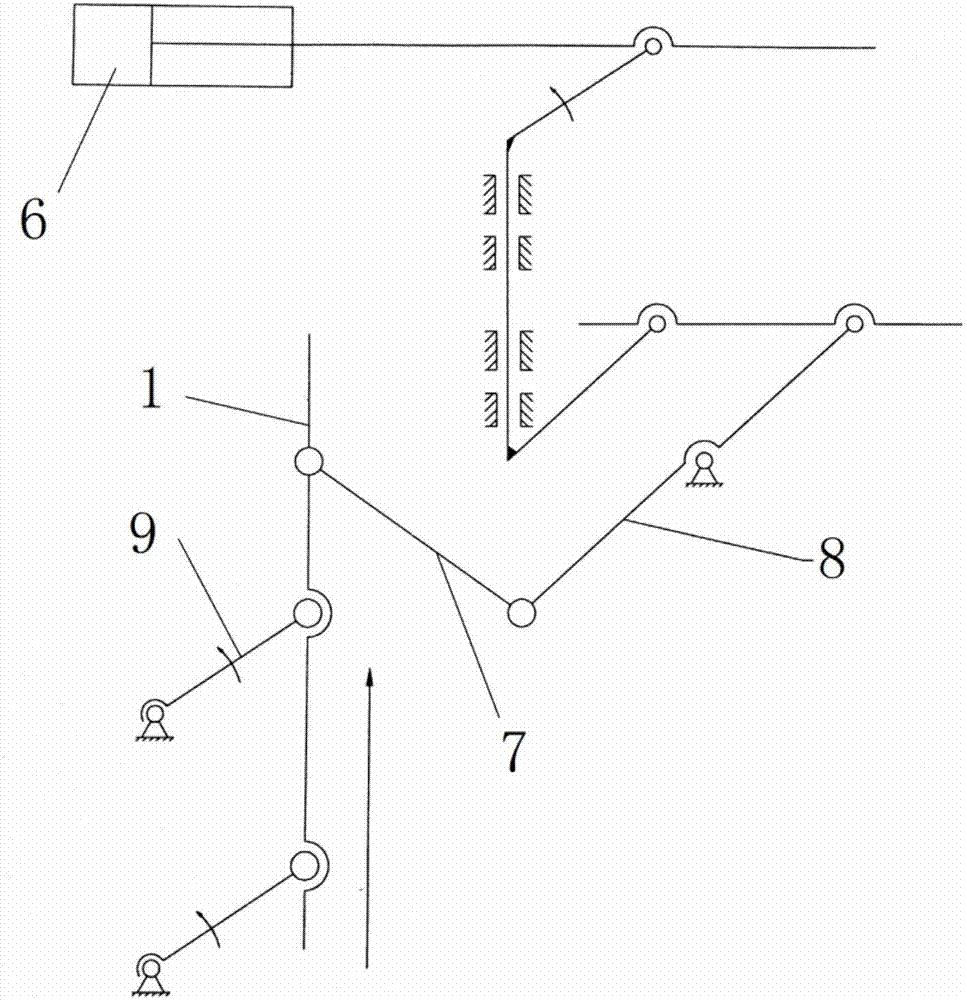

[0032] A structural movement method that uses rolling contact to ensure the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com