Modular manufacturing method of large conversion furnace

A manufacturing method and reformer technology, applied in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of low manufacturing efficiency, huge manufacturing cost and long manufacturing cycle of traditional methods, so as to reduce manufacturing intensity and shorten manufacturing cycle , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated below by specific examples.

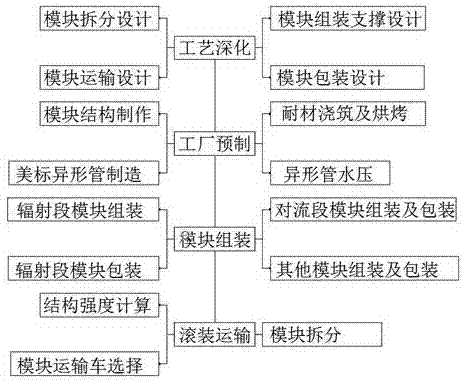

[0019] Such as figure 1 As shown, a modular manufacturing method for a large-scale reformer, including

[0020] Step 1. According to the entire manufacturing process, the manufacturing process of the reformer is divided into four parts: the process deepening stage, the factory prefabrication stage, the module assembly stage, and the roll-on transportation stage;

[0021] Step 2. In the process deepening stage, the reformer is divided into four parts: modular disassembly, module assembly and support, and module packaging and transportation; among them, when dismantling the mold in blocks, it is disassembled according to the functions of each part in the reformer. Divided into several radiation section modules, convection section modules, roof modules, chimney and air duct modules;

[0022] Step 3. In the factory prefabrication stage, according to the plan of the process deepening stage, first im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com