Tilting plate cutter storage servo absolute value motor control method

A technology of motor control and absolute value, which is applied in the field of tool magazines, can solve problems such as mechanical position displacement, and achieve the effects of simplified mechanical design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

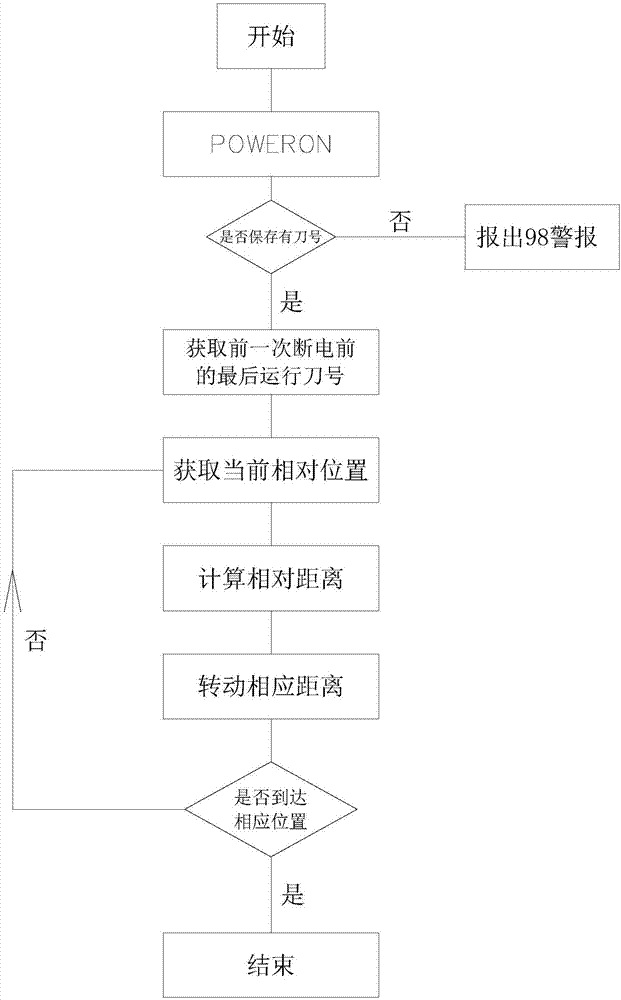

[0014] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0015] As we all know, there is a position control mode in the servo drive control system. In this control mode, the driver can receive the pulse signal from the host computer (CNC system, PLC, etc.) to precisely control the servo motor to the position specified by the host computer. In addition, there is also an internal position control mode in the servo drive control system, which is equivalent to the position control mode and precisely controls the operation of the servo motor through pulse signals.

[0016] Different from the position control mode, the pulse signal in the internal position control mode does not come from the host computer, but comes from the inside of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com