A method for controlling the production and installation accuracy of structural components in the construction industry

A control method and installation precision technology, applied in the field of construction industry component production and installation precision control technology, can solve problems such as backward dimensional precision control methods, and achieve the effect of avoiding rework, guaranteeing construction period, and reducing labor input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment discloses a method for controlling the production and installation accuracy of structural components in the construction industry, including the following steps:

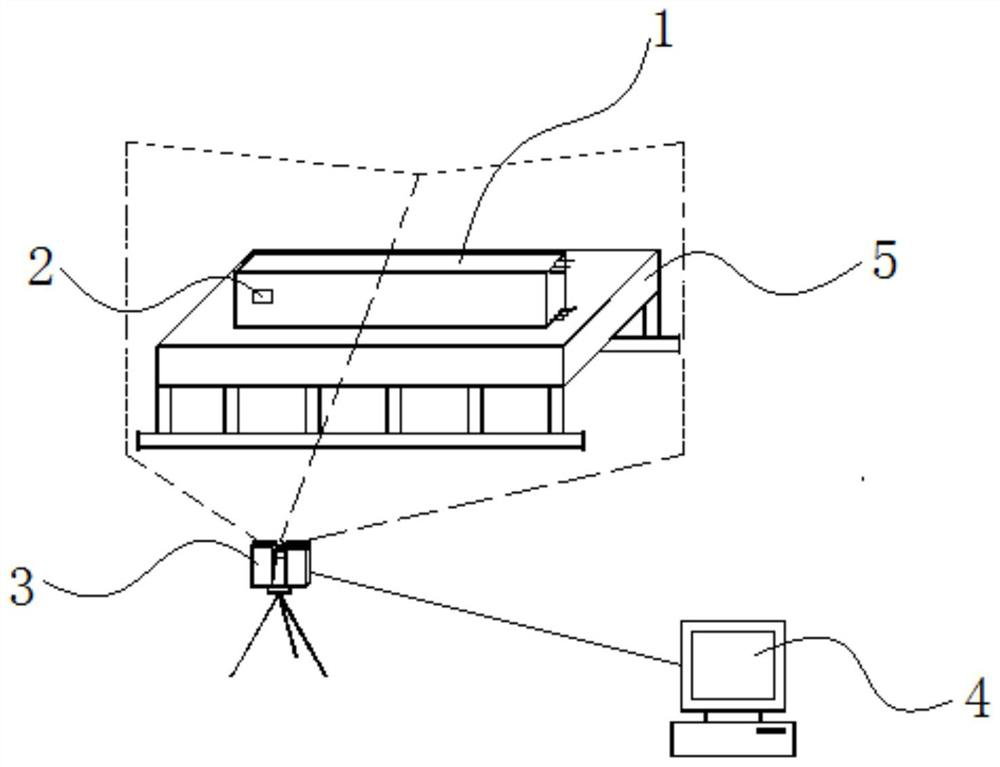

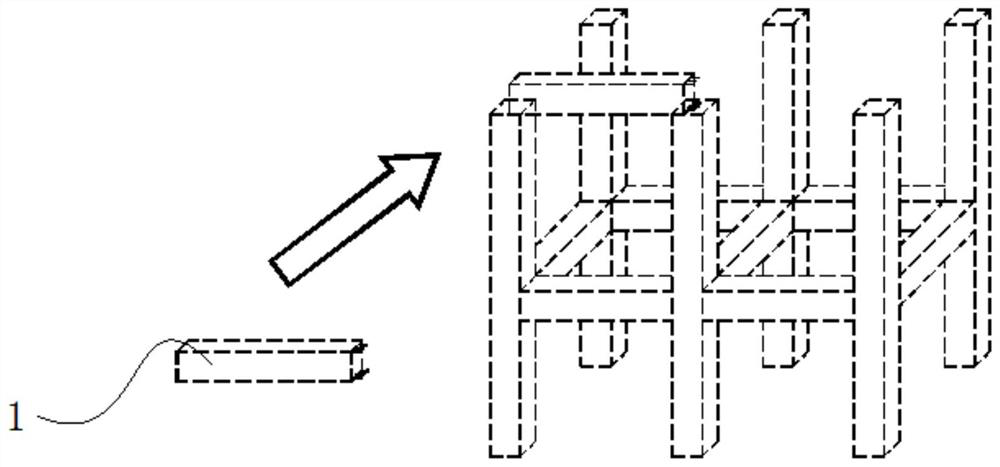

[0035] 1) Number the processed prefabricated components 1 in the factory or the production site, and set a label 2 for each prefabricated component. Wherein, the prefabricated component 1 is a metal component, a concrete component, an electromechanical equipment pipeline or a door and window. The label information of the label 2 includes number information, physical information, geometric information and local coordinate information in the project of the prefabricated component 1, and the number information corresponds to the physical, geometric and local coordinate information one by one. see figure 1 , in this embodiment, the label 2 is a radio frequency identification or two-dimensional code label arranged on the surface of the component. In actual production, the tag 2 can also be select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com