Fast virtual numerical value test method for aerodynamic performance of baffled combustor

A technology for aerodynamic performance and numerical testing, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of imperfect basic database and model library, weak foundation, and yet to be established.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] The fast virtual numerical test method of the aerodynamic performance of the small turbine engine baffle type combustor of the present invention comprises the following steps:

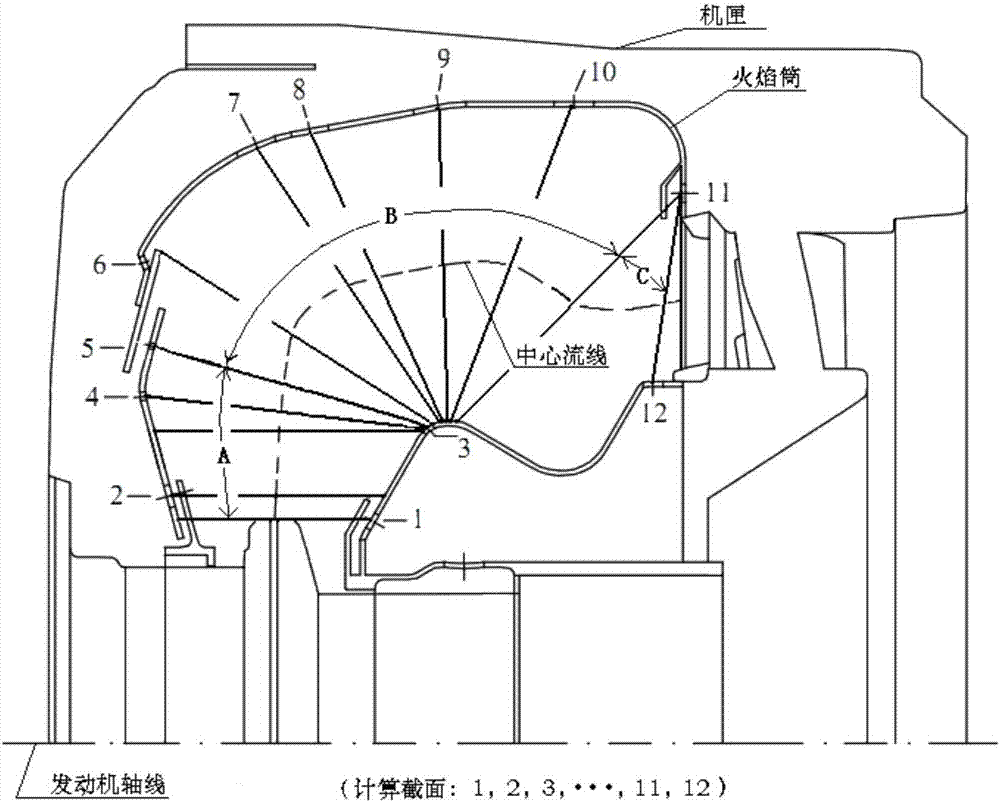

[0034] Step 1. Partitioning of the one-dimensional aerodynamic model of the combustion chamber and selection of the calculation section.

[0035] Step 2. Input the geometric parameters and initial conditions of the combustion chamber model, including: combustion chamber inlet air flow, inlet air total pressure, inlet air total temperature, fuel flow, outlet total temperature, combustion chamber combustion efficiency, etc.

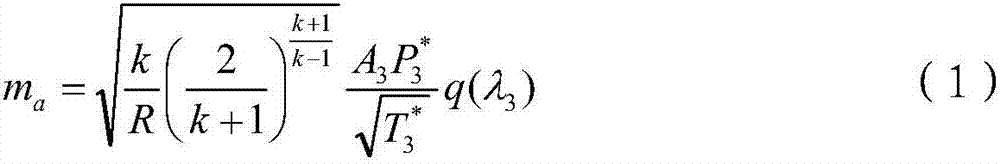

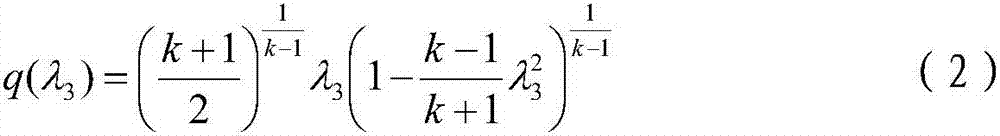

[0036] Step 3. Calculate the inlet status and overall performance parameters of the baffle combustor, including:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com