A whole-process quality traceability method for products

A full-process, product-based technology, applied in the direction of instruments, calculations, computer components, etc., can solve the problems of easy loss of inner layer information, easy identification of adverse effects, etc., to reduce processing workload, reduce processing costs, and prevent loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

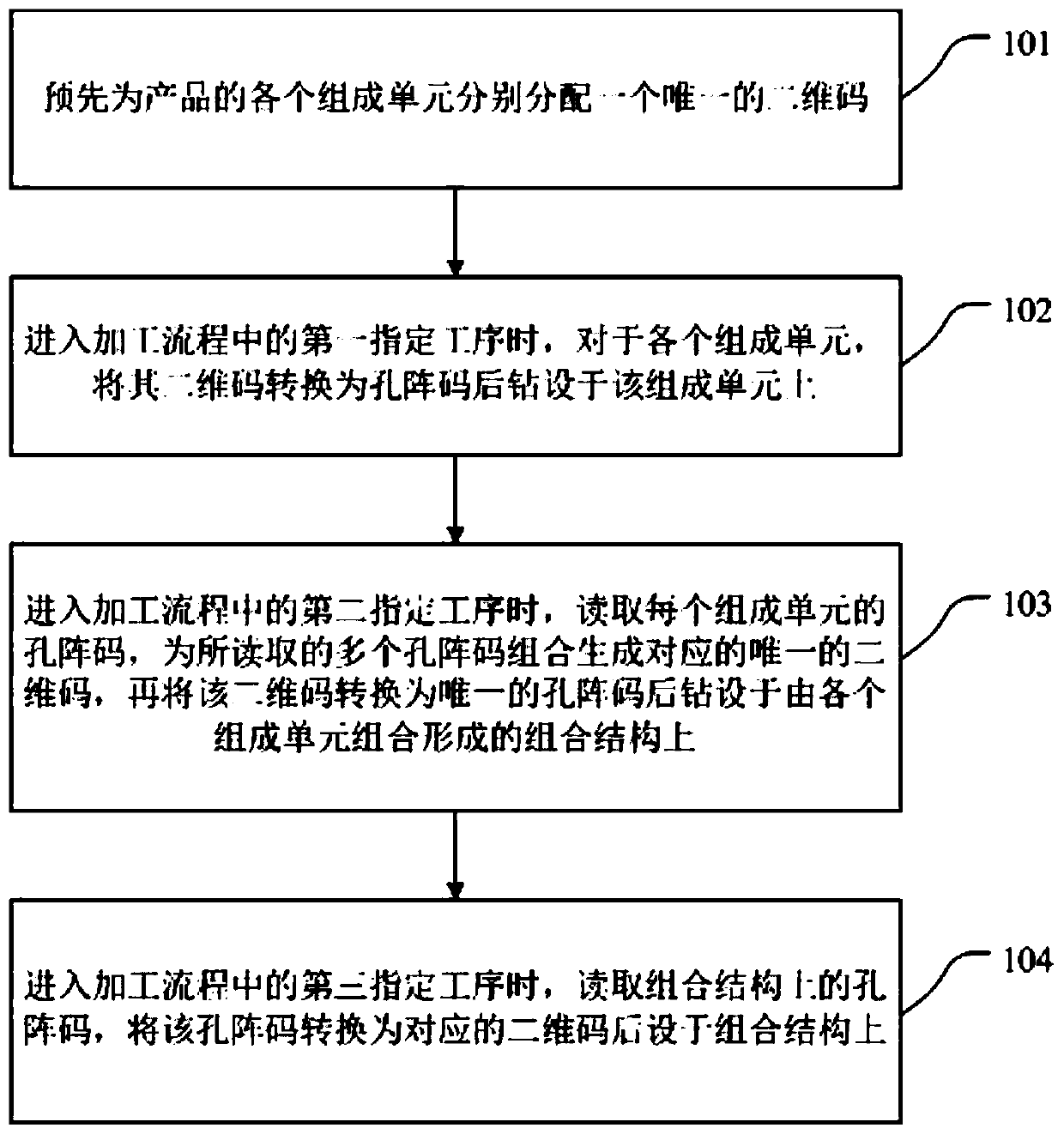

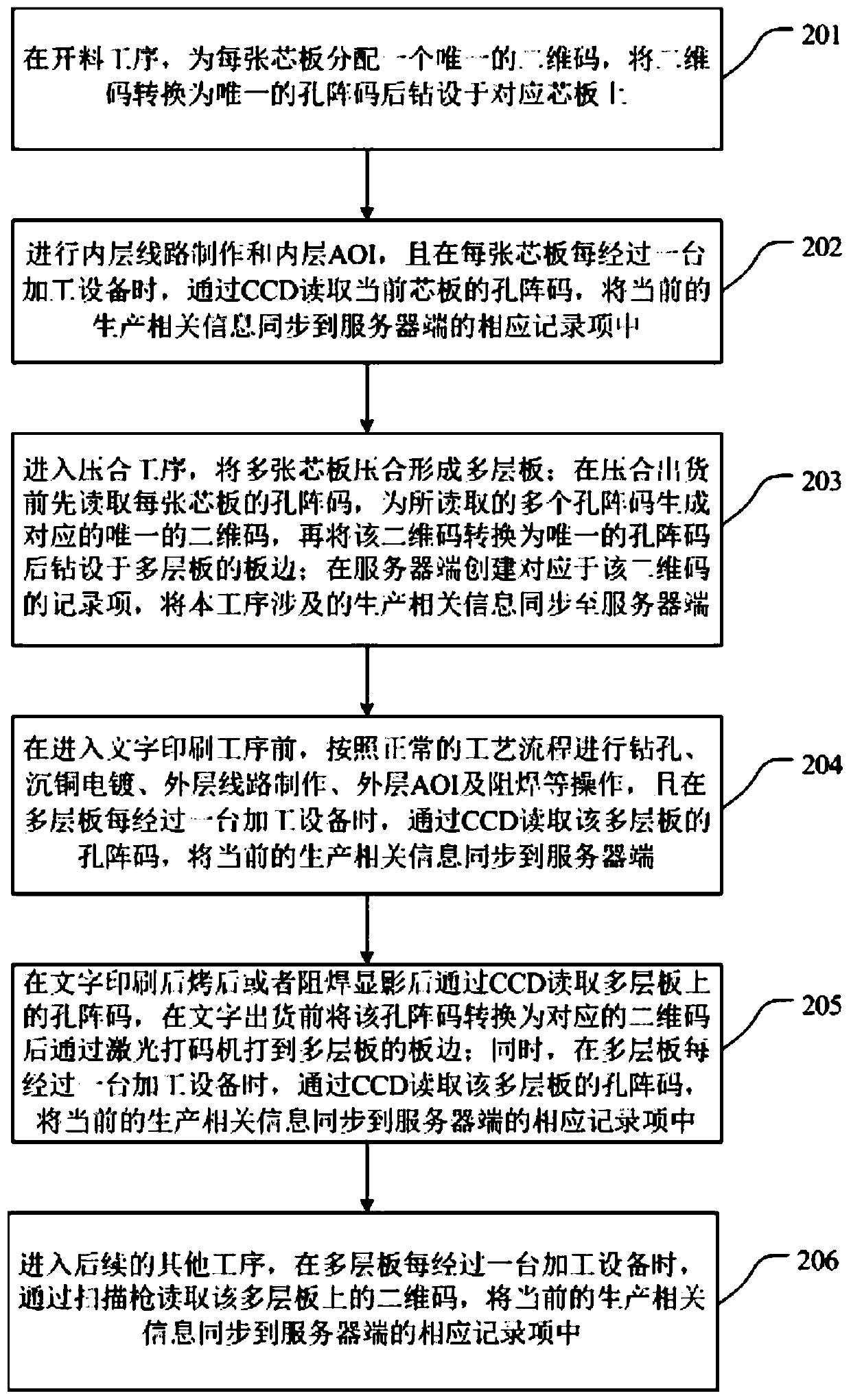

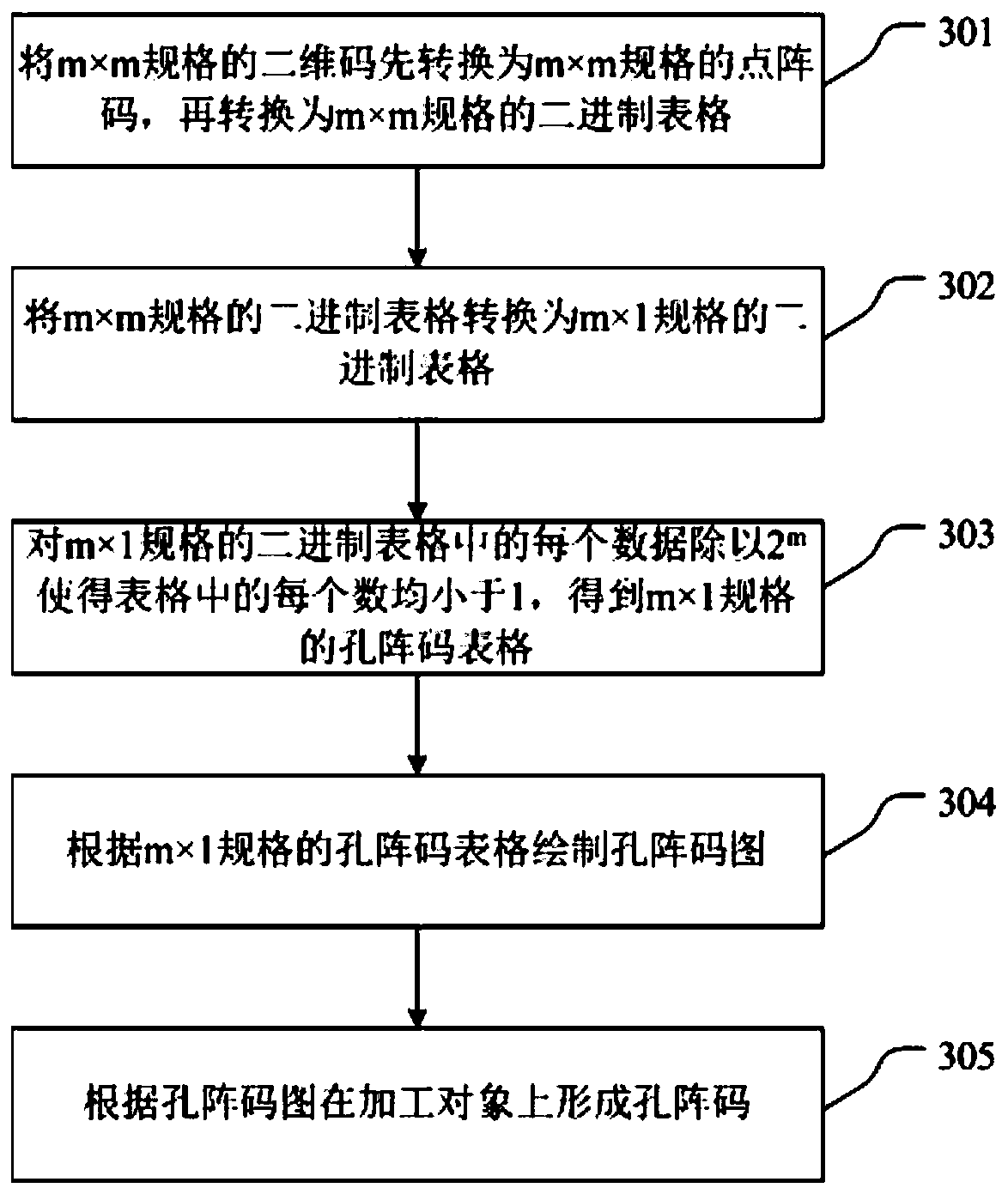

[0061] see figure 1 , for a product processed by a plurality of constituent units according to a preset processing flow (including multiple processes), this embodiment provides a whole-process quality traceability method, including steps:

[0062] Step 101, assign a unique two-dimensional code to each component unit of the product in advance.

[0063] Two-dimensional code is an information identification technology developed by combining the three technologies of computer, communication and photoelectric sensing. It is a black and white geometric figure arranged according to certain rules, and the black and white positions in the figure correspond to "1" and "0" respectively, thus forming a sequence of binary characters, which can represent numbers, characters and other information.

[0064] According to different quality traceability requirements and structural characteristics of different products, in this step, a corresponding QR code can be assigned to all the components ...

Embodiment 2

[0150] see Figure 12 For a non-combined product processed according to a preset processing flow (including multiple processes), since the product does not involve multiple constituent units and the transfer of information from the inner layer to the outer layer, this embodiment provides another A method for tracing the quality of a product throughout the process, comprising the steps of:

[0151] Step 1201, assign a unique two-dimensional code to the product in advance.

[0152] Step 1202, when entering the first designated process in the above processing flow, convert the two-dimensional code into a hole matrix code and then drill and set it on the current product.

[0153] It should be noted that the first specified process may be any process specified in the processing flow, and is not limited to the first process in the processing flow. In a specific implementation, the earliest process in the processing flow that will have a negative impact on the recognition of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com