Improved TO-220EW lead frame

A TO-220EW, lead frame technology, applied in the field of semiconductor packaging, can solve the problems of enterprise loss, poor insulation effect, poor plastic sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

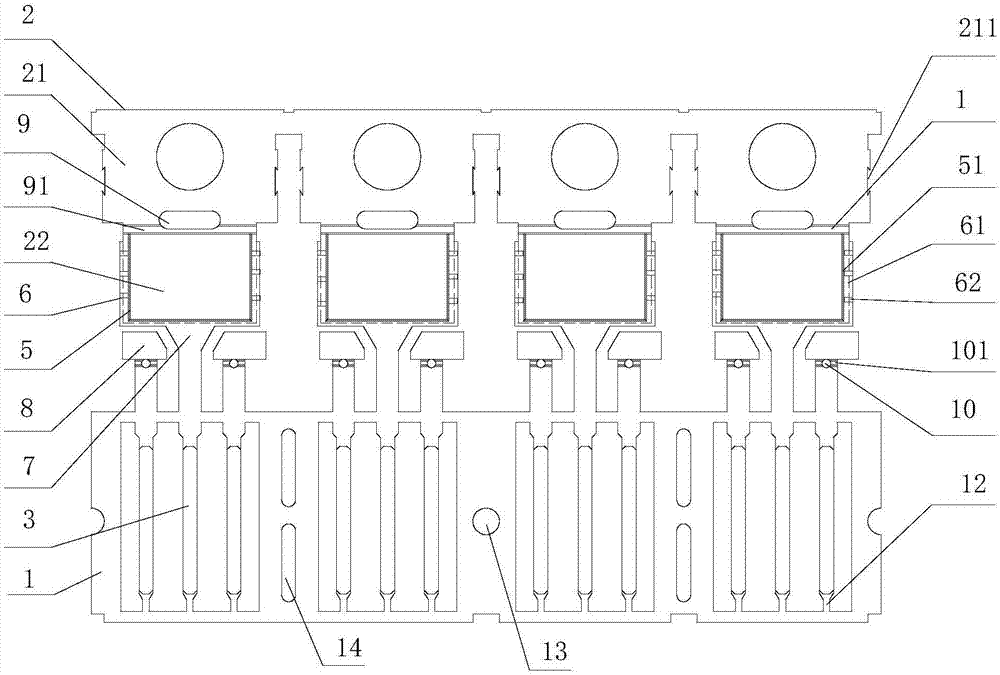

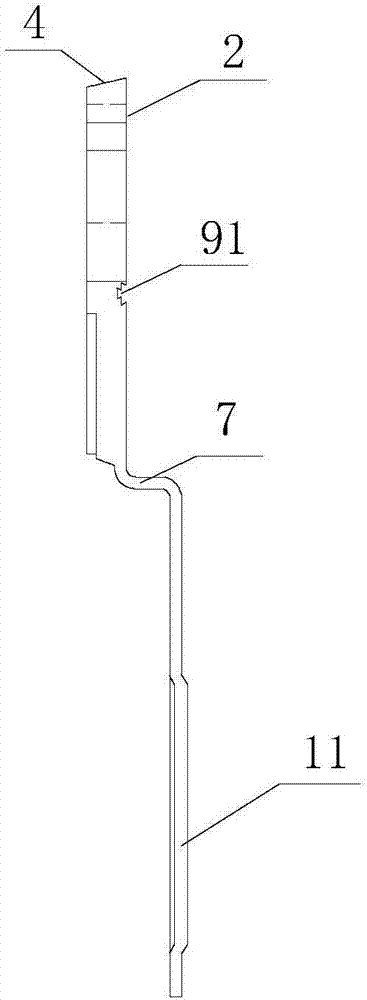

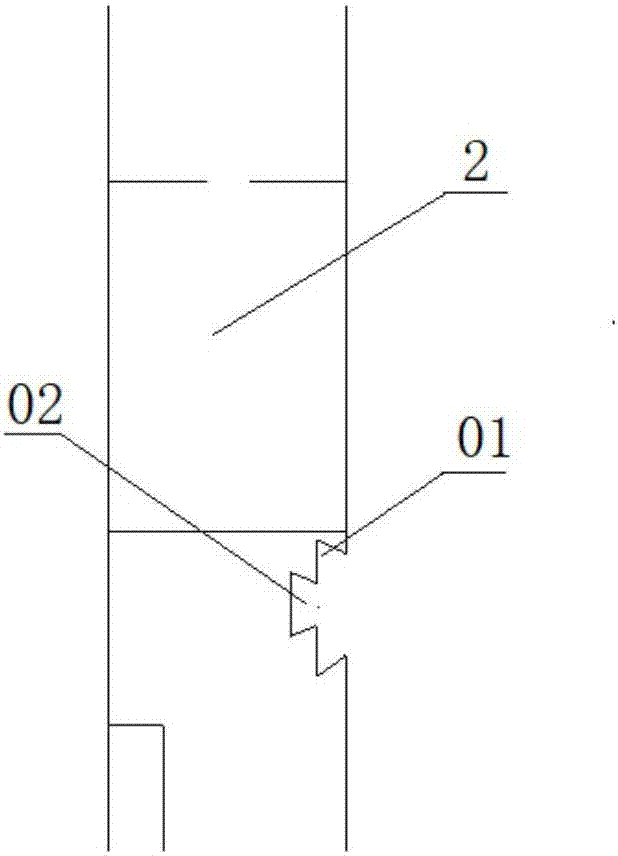

[0020] Embodiment 1: An improved TO-220EW lead frame, including several frame units connected in series by connecting ribs 1, each frame unit includes a base body 2 and a pin area 3, and the base body 2 includes a heat sink area 21 and the carrier area 22, the thickness direction of the substrate 2 is provided with a reverse flow slope 4, and the included angle of the reverse flow slope 4 is 60°; both sides of the heat sink area 21 are provided with a trapezoidal notch 211, and the inner surface of the trapezoidal notch 211 has a tapered blind hole; the chip loading area 22 is provided with a chip mounting groove, and chip fixing structures 5 are arranged on both sides of the chip mounting groove; A baffle that can be inserted movably in the interior; waterproof structures 6 are provided on both sides of the loading area 22; The water guide channel 62, the water guide channel 62 is an open horn-shaped structure; the pin area 3 is provided with three pins, the top of the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com