CoCrMo powder hot isostatic pressing forming method based on PREP technique

A technology of hot isostatic pressing and process, which is applied in the field of static pressing, can solve the problems of difficult to meet the SLM forming process and low yield of fine powder, and achieve the goal of improving material utilization, improving various performances, and reducing forming costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The hot isostatic pressing method of CoCrMo powder based on PREP process includes the following steps:

[0019] 1) CoCrMo alloy powder was prepared by PREP process, and the particle size was D50=100μm obtained by classification;

[0020] 2) The CoCrMo alloy powder is machined into a sheath with 304 stainless steel, cleaned with acetone, annealed at high temperature, and then checked for leaks;

[0021] 3) The CoCrMo alloy powder after leak detection is formed by hot isostatic pressing equipment to obtain a formed part, the pressure holding temperature is 1200°C, the pressure is 130MPa, the heating rate is 15°C / min, and the cooling rate is 5°C / min;

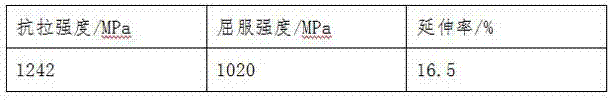

[0022] 4) Use wire cutting samples on the formed parts in step 3) to test the tensile properties at room temperature.

[0023]

Embodiment 2

[0025] The hot isostatic pressing method of CoCrMo powder based on PREP process includes the following steps:

[0026] 1) CoCrMo alloy powder was prepared by PREP process, and the particle size was D50=50μm obtained by classification;

[0027] 2) The CoCrMo alloy powder is machined into a sheath with 304 stainless steel, cleaned with acetone, annealed at high temperature, and then checked for leaks;

[0028] 3) The CoCrMo alloy powder after leak detection is formed by hot isostatic pressing equipment to obtain a formed part, the pressure holding temperature is 1180°C, the pressure is 100MPa, the heating rate is 12°C / min, and the cooling rate is 8°C / min;

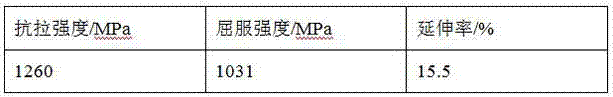

[0029] 4) Use wire cutting samples on the formed parts in step 3) to test the tensile properties at room temperature.

[0030]

Embodiment 3

[0032] The hot isostatic pressing method of CoCrMo powder based on PREP process includes the following steps:

[0033] 1) CoCrMo alloy powder was prepared by PREP process, and the particle size was D50=150μm obtained by classification;

[0034] 2) The CoCrMo alloy powder is machined into a sheath with 316L stainless steel, cleaned with acetone, annealed at high temperature, and then checked for leaks;

[0035] 3) The CoCrMo alloy powder after leak detection is formed by hot isostatic pressing equipment to obtain a formed part, the pressure holding temperature is 1220°C, the pressure is 145MPa, the heating rate is 10°C / min, and the cooling rate is 2°C / min;

[0036] 4) Use wire cutting samples on the formed parts in step 3) to test the tensile properties at room temperature.

[0037] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com