Narrow-gap submerged-arc welding method and equipment for saddle-shaped adapter tube groove

A submerged arc welding and narrow gap technology, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of high technical requirements for welders, high labor intensity, low welding quality and efficiency, and overcome welding labor intensity Large, overcome the effect of high labor intensity and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

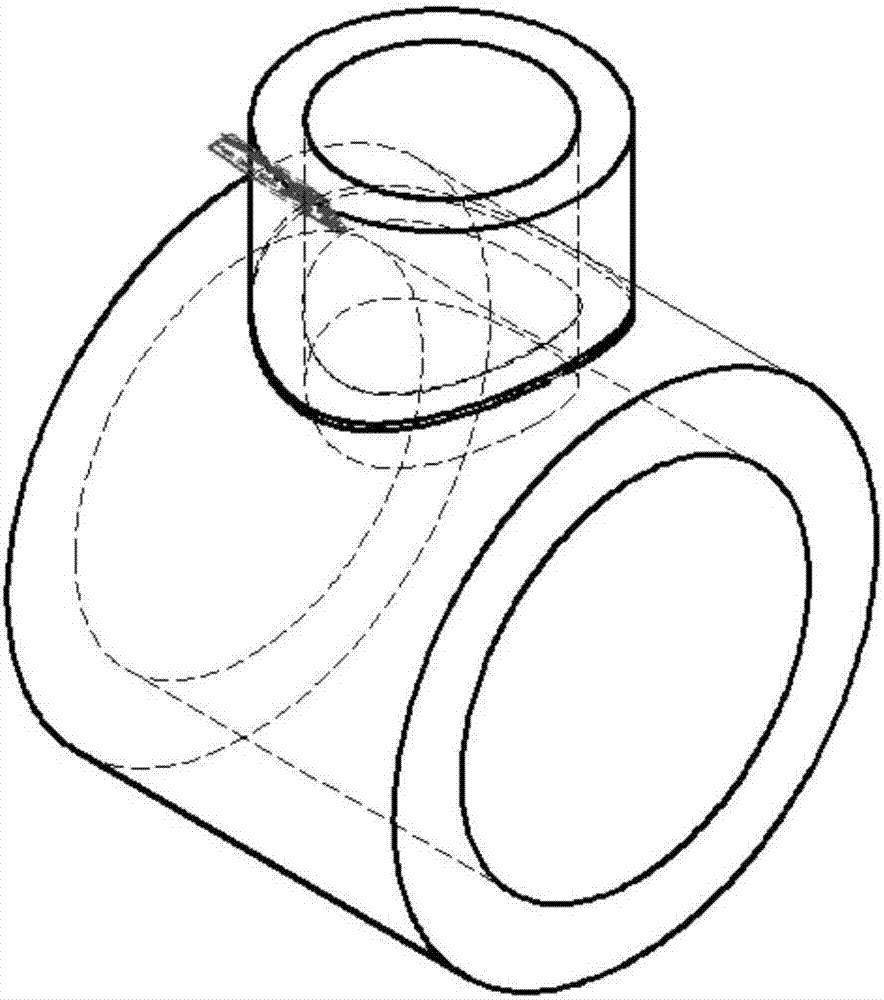

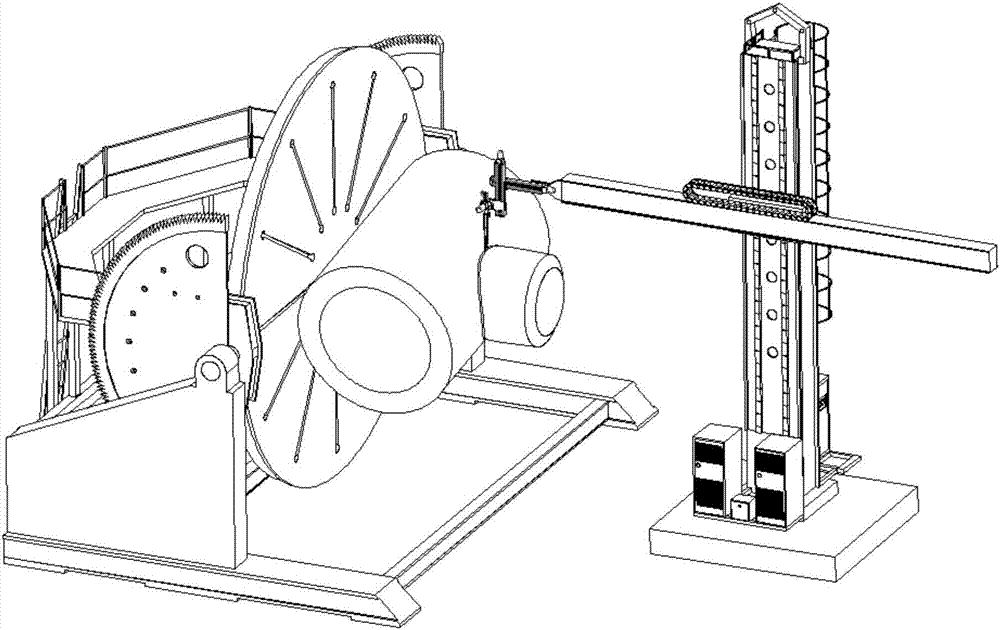

[0018] Such as Figure 1 to Figure 3 As shown, a narrow gap submerged arc welding method for a saddle-shaped pipe groove includes the following steps:

[0019] A saddle-shaped groove A is processed on the outer wall of the barrel joint workpiece, and a saddle-shaped groove B is processed at the nozzle of the connecting workpiece; the saddle-shaped groove A and the saddle-shaped groove B are saddle-shaped single U lines with blunt edges Groove.

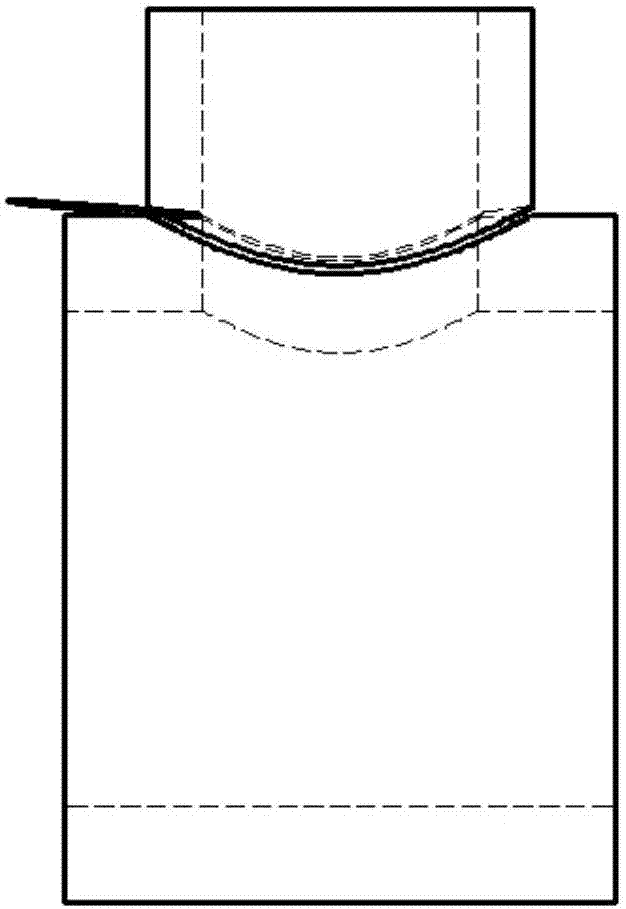

[0020] A saddle-shaped single U bevel is used between the butt joints of the barrel joint workpiece and the connecting pipe workpiece, and a single U-shaped narrow gap submerged arc groove with a blunt edge is processed on the two workpieces respectively.

[0021] During processing, there is no need to leave a margin for the two circular blank workpieces, and the groove is directly processed under the drawing size. The groove form is a single U-shaped groove with a blunt edge.

[0022] The saddle-shaped groove A and the saddle-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com