A Noise Suppression Method of Leading Edge Slats Based on Zero Mass Jet Control

A leading-edge slat and jet control technology, which is applied in the direction of aircraft control, affecting the air flow passing through the aircraft surface, wings, etc., can solve the problems of arranging pipe bleed air, difficulties, etc., and achieve flexible control, fast response, and high energy efficiency. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

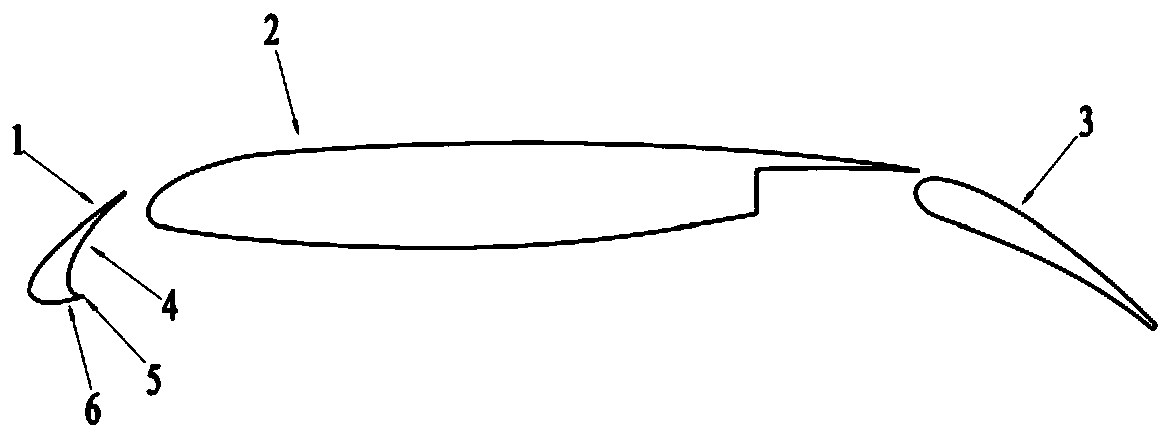

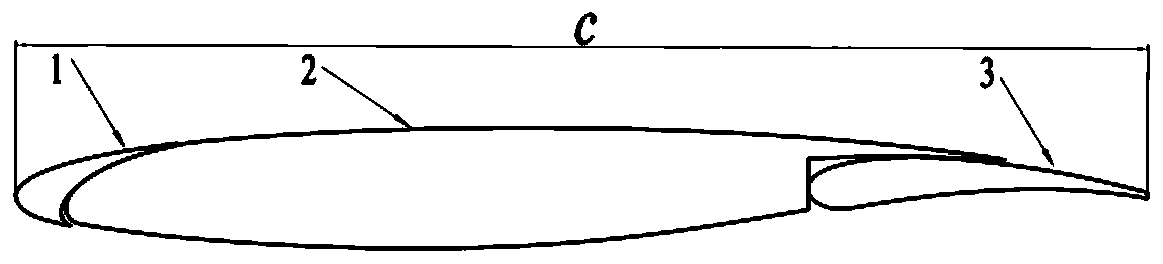

[0026] Taking the multi-section wing 30P30N as an example, the present invention introduces a method for suppressing leading-edge slat noise based on zero-mass jet flow. The multi-section airfoil is composed of three parts: leading edge slat, main wing and trailing edge flap. The chord length of the wing is C. figure 1 and 2 , 1 denotes the slat, 2 denotes the main wing, 3 denotes the flap, 4 denotes the slat cavity, 5 denotes the slat tip (cusp), and 6 denotes the slat suction surface.

[0027] The specific steps for reducing the noise of leading edge slats by using zero mass jet are as follows:

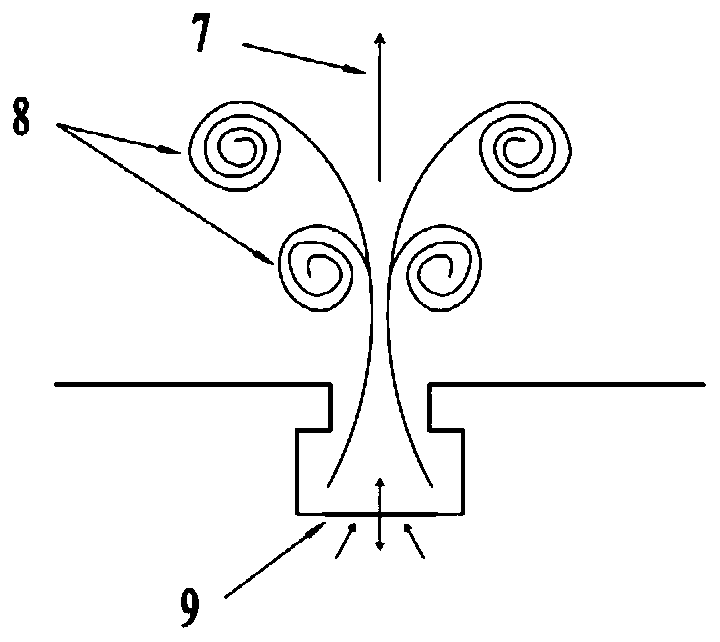

[0028] Step 1: Select a zero-mass jet actuator. The average speed of the jet generated by the exciter is 60-120m / s, and the excitation frequency can be adjusted, and the adjustment range is 1000-4000Hz. The zero-mass jet actuator can be a piezoelectric thin-film type or a piston-type zero-mass jet actuator. When the zero-mass jet actuator works, the piston or the piezoelectric f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com