Control method of mobile vehicle maintenance equipment

A technology for vehicle maintenance and control methods, which is applied to mobile jacks, lifting devices, etc., can solve the problems of lack of layers, single box structure, and increased transportation space, and achieves the effect of improving reliability and improving machine efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The control method of the mobile vehicle maintenance equipment of the present invention will be further described in detail through specific embodiments below.

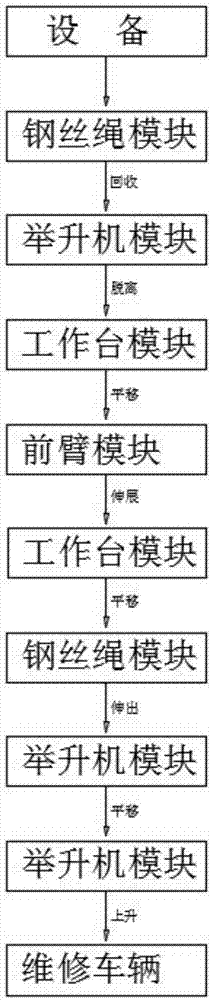

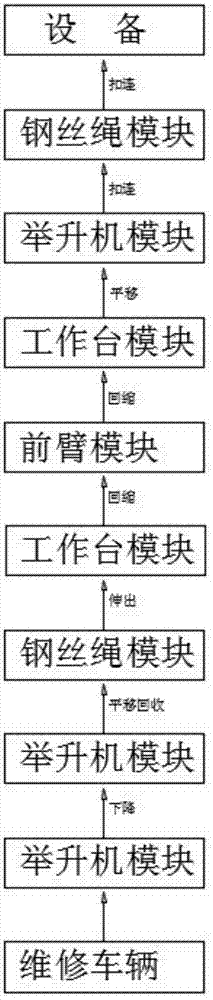

[0013] This embodiment provides a control method for mobile vehicle maintenance equipment, and the specific implementation method includes the following steps:

[0014] Step 1: Start the first button command, the wire rope module starts, controls the wire rope to recover, and makes the lift disengage;

[0015] Step 2: Start the second button command to start the translation and extension movement of the workbench module. When it is detected that the workbench module has moved to a fixed position, the workbench module will suspend operation;

[0016] Step 3: start the third button command, the forearm module is driven, and the forearm module is controlled to move to the detection position;

[0017] Step 4: Start the fourth key command, and the workbench module continues to move in translation to the detection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com