A method for increasing the number of times of carbon black recycling

A carbon black and frequency technology, which is applied in the field of increasing carbon black recycling times, can solve the problems of increasing carbon black recycling times, less recycling times, and high production costs, and achieves the effects of easy implementation, reduced usage, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

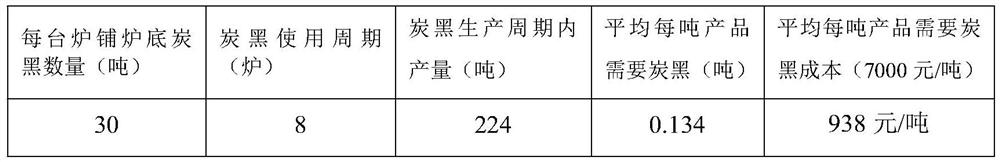

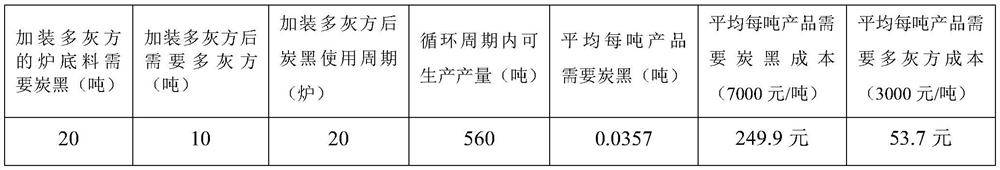

Examples

Embodiment 1

[0021] To the furnace bottom of the graphitization furnace, add an insulating material with a total volume of 20m long × 3.7m wide × 0.75m high. The insulating material includes N330 type wet carbon black and carbon multi-ash square, wherein the total volume of adding carbon multi-ash square is 1 / 3 of the total volume of the thermal insulation material, the method comprises the following steps:

[0022] S1. Prepare a carbon multi-gray square with uniform size, and its preparation method is:

[0023] ① Purchase a finished product with a cross-sectional area of 200mm×200mm and a height of 2m.

[0024] ② Use a cutting lathe to evenly divide the whole multi-gray square to obtain multiple carbon multi-gray squares with a cross-sectional area of 200mm×200mm and a height of 500mm;

[0025] ③Collect the carbon multi-ash square obtained after the segmentation, and transport it to the graphitization furnace for standby;

[0026] S2. After the graphitization furnace is cooled, plac...

Embodiment 2

[0029] The difference between the first embodiment and the second embodiment is that: the total volume of the carbon multi-ash square added to the heat preservation material of the graphitization furnace is different.

[0030] To the furnace bottom of the graphitization furnace, add an insulating material with a total volume of 20m long × 3.7m wide × 0.75m high. The insulating material includes N330 type wet carbon black and carbon multi-ash square, wherein the total volume of adding carbon multi-ash square is 1 / 4 of the total volume of the insulation material, the method comprises the following steps:

[0031] S1. Prepare a carbon multi-gray square with uniform size, and its preparation method is:

[0032] ① Purchase a finished product with a cross-sectional area of 200mm×200mm and a height of 2m.

[0033] ② Use a cutting lathe to evenly divide the whole multi-gray square to obtain multiple carbon multi-gray squares with a cross-sectional area of 200mm×200mm and a height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com