Manual regeneration, softening and purifying all-in-one machine and water softening and producing method

A manual regeneration, all-in-one technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Use experience and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with accompanying drawing:

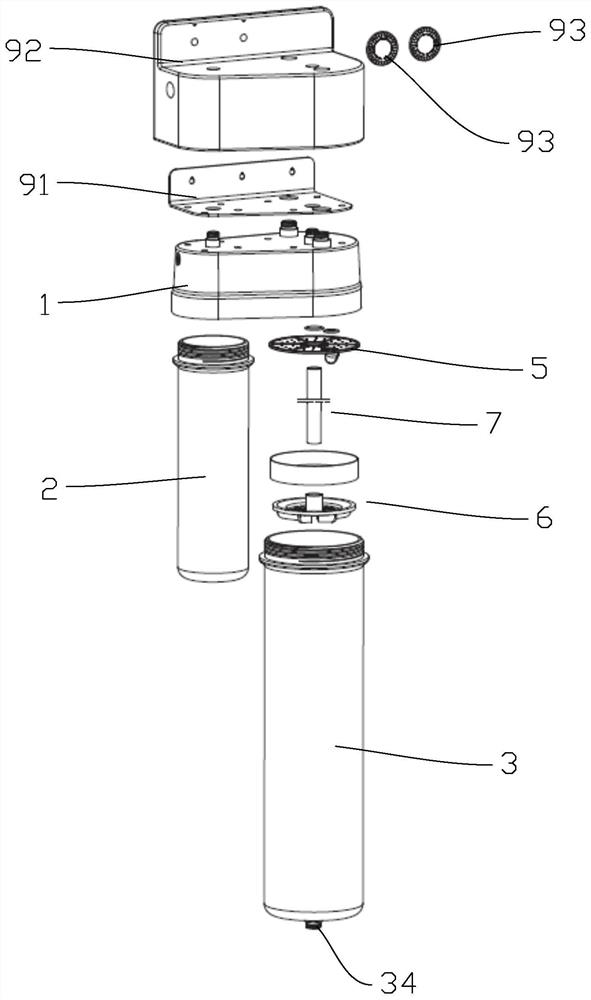

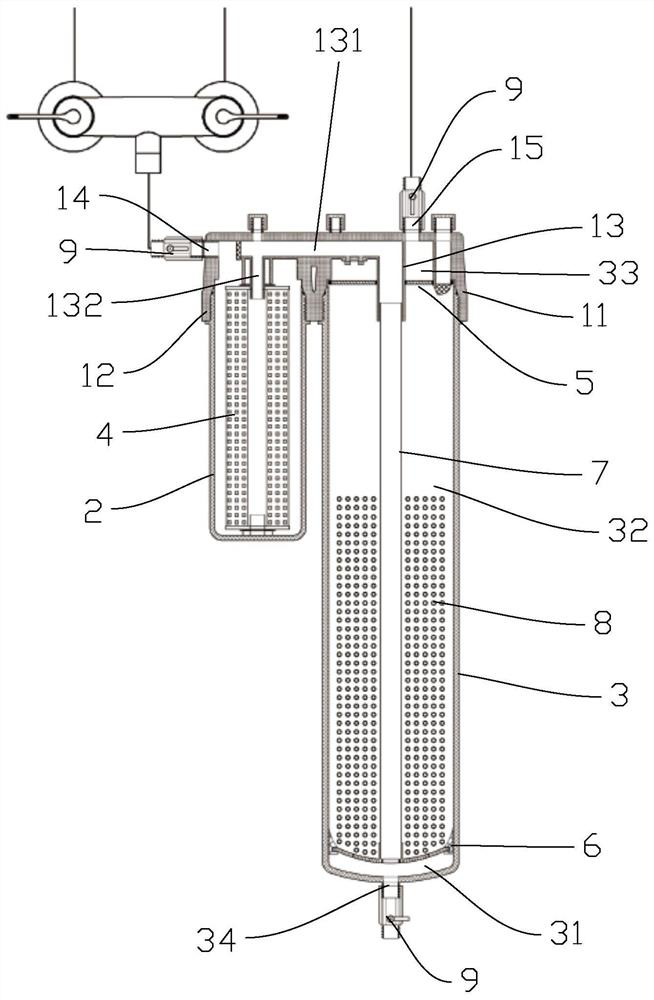

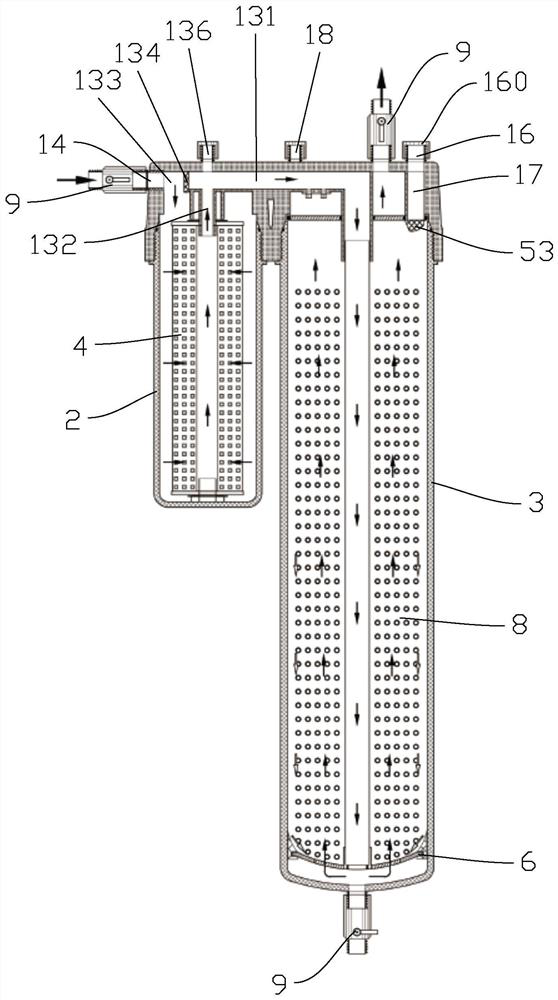

[0077] Such as Figure 1 to Figure 18 The shown manual regenerative soft-cleaning integrated machine includes a valve cover 1, and the valve cover 1 includes a soft water cover 11 and a water purification cover 12 of an integral structure, and a communication is provided between the water purification cover 12 and the soft water cover 11. The connecting pipe 13 of the two, the water purification cover 12 is provided with a raw water inlet 14, the soft water cover 11 is provided with a soft water outlet 15, and the water purification cover 12 and the soft water cover 11 are respectively detachably connected with The water purification tank 2 and the soft water tank 3 with the upper end open, the water purification inner cavity formed by the water purification cover 12 and the water purification tank 2 is provided with a net that can purify the water quality flowing from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com