Textile fabric washing machine of special improved structure

A technology for textile fabrics and cleaning machines, which is applied in the processing of textile material containers, spray/jet textile material processing, ultrasonic/sonic fiber processing, etc. Conducive to the use of subsequent processing and the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

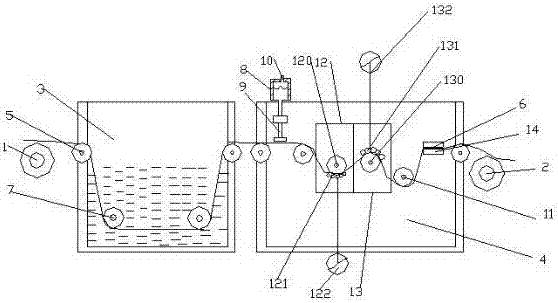

[0015] Such as figure 1 Shown, as the first embodiment of the present invention, a kind of textile fabric washing machine of special improved structure, comprises feed roller 1 and discharge roller 2, is provided with between described feed roller 1 and discharge roller 2 The first box body 3 and the second box body 4, the textile fabrics pass through the first box body 3 and the second box body 4 in turn, and the side walls of the first box body 3 and the second box body 4 are installed There are upper guide rollers 5, and cleaning liquid is filled in the first box body 3, and a plurality of sets of lower guide rollers 7 for conveying fabrics are also installed at the bottom of the first box body 3, and the second box body The upper surface of 4 is also provided with a high-pressure box 8, the high-pressure box 8 stores mixed dry ice, and the high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com