Production technique of flame-retarding fabric

A flame-retardant fabric and production process technology, applied in the field of flame-retardant fabric production technology, can solve the problems of complicated steps and long processing time, and achieve the effect of simple process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

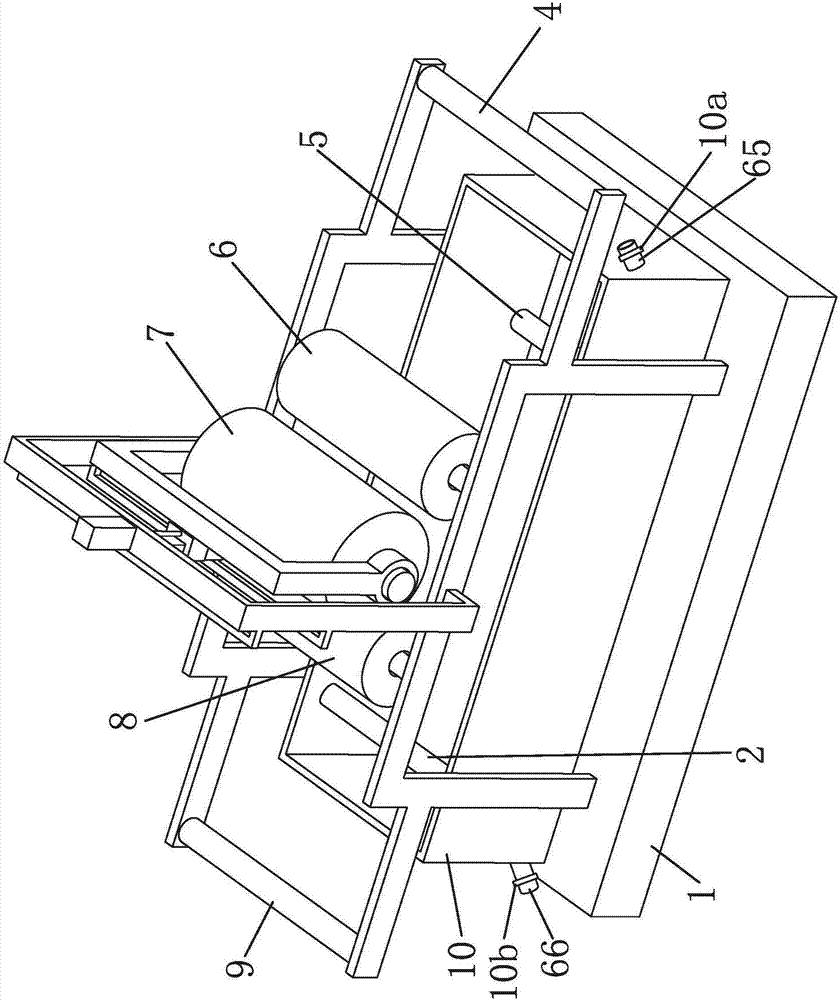

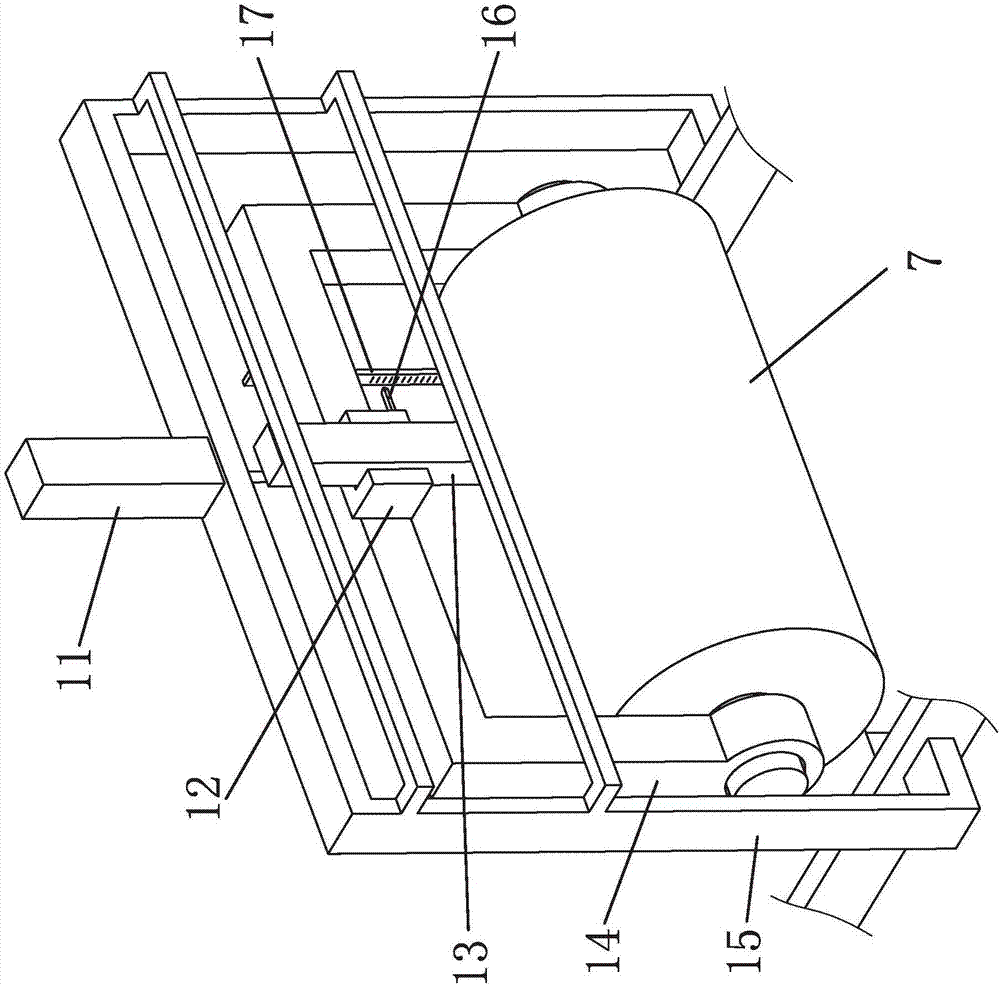

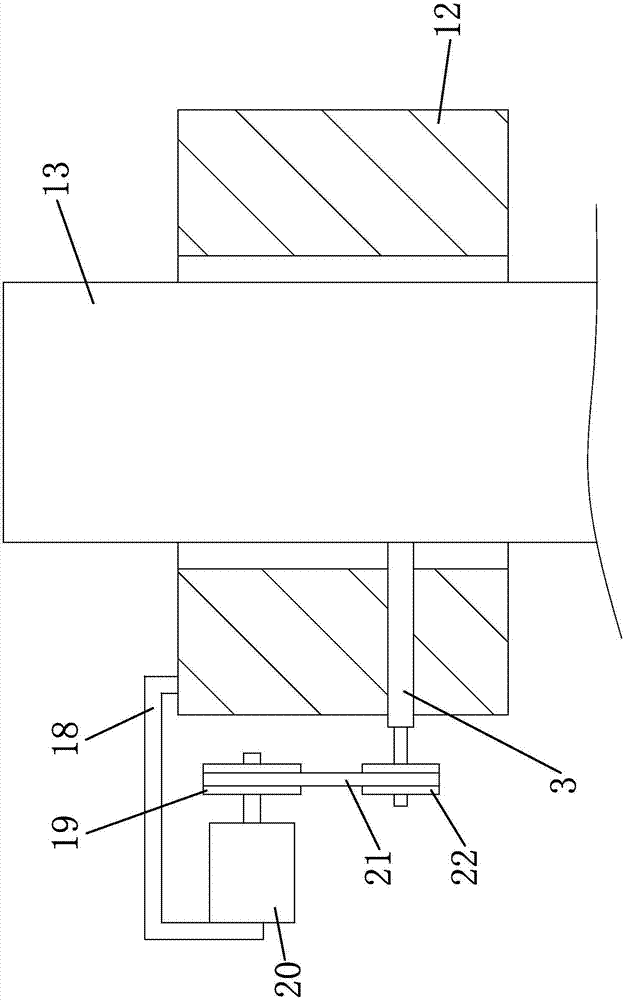

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0042] The manufacturing process of the flame-retardant fabric includes the following steps: a. Pour the finishing liquid into the padding system, put the fabric into the padding system for padding, one dipping and one rolling, and the excess rate is 68-76%; b. 1. Put the padded fabric into an oven for drying, the drying temperature is 96-110°C, and the drying time is 20-40min; c. Put the dried fabric into a baking machine to bake, and bake The temperature is 120-135°C, and the baking time is 60-90 minutes; d. Put the baked fabric into a washing machine and wash it for 2-3 times; e. Put the washed fabric into the oven for the second time Drying in middle temperature, the drying temperature is 135-145°C, and the drying time is 4-6min, and the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com