Line-shaped assembly type core column steel plate shear wall and assembly construction method thereof

A steel plate shear wall and steel plate shear force technology, which is applied to walls, building components, buildings, etc., can solve the problems of reducing the overall structural safety performance, affecting structural safety, and low efficiency, achieving reliable structural safety performance and enhancing connection strength , Enhance the effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be explained in more detail through the following embodiments:

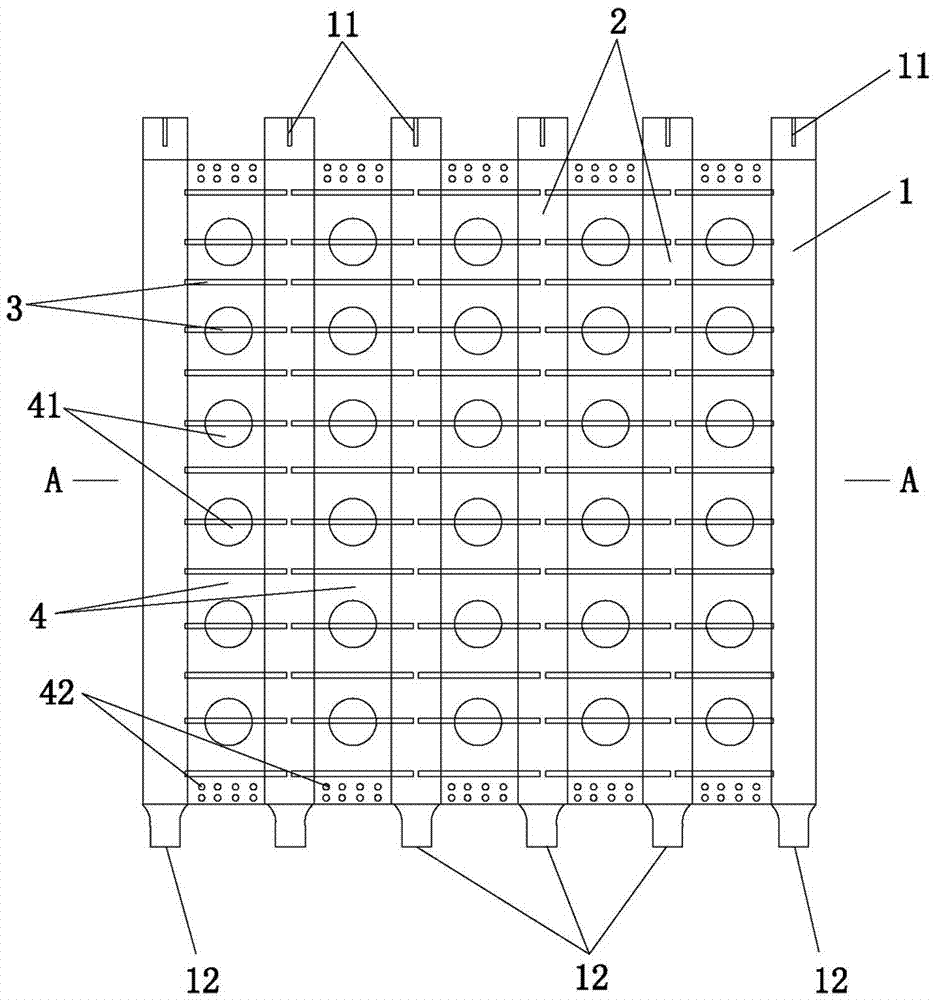

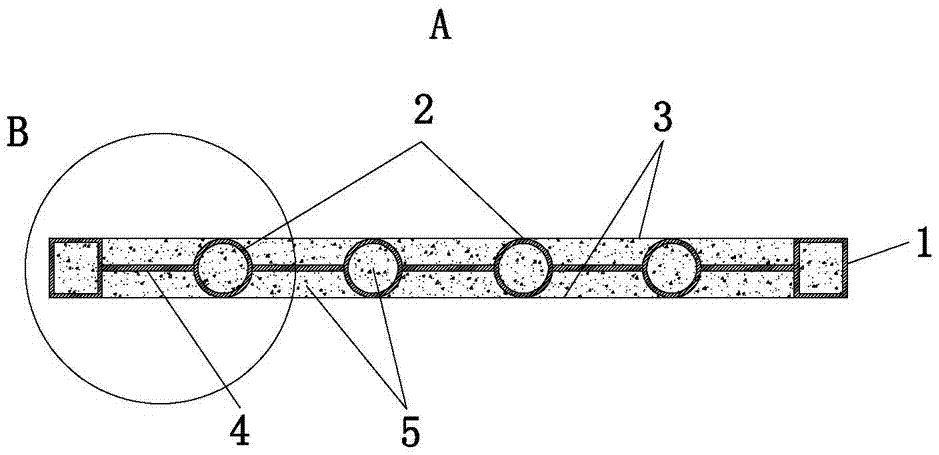

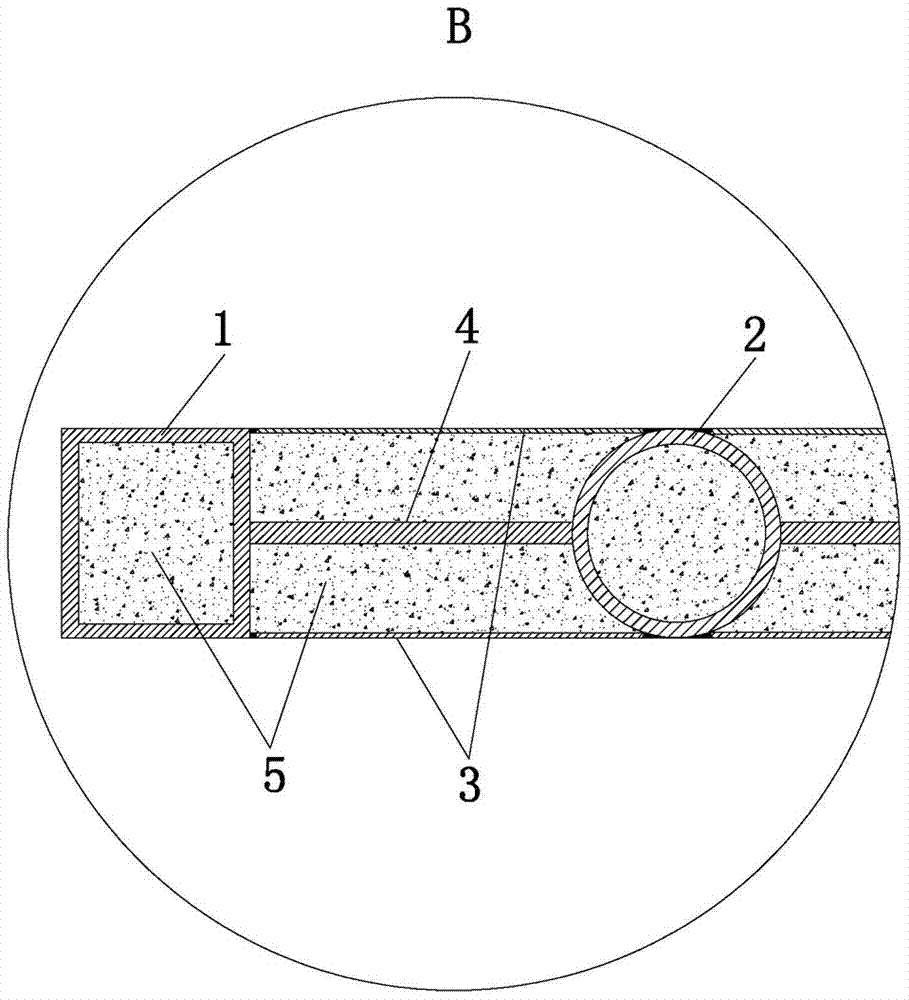

[0030] Such as figure 1 , 2 , a kind of inline assembled core column steel plate shear wall shown in 3, comprises square edge stiffening column 1, circular core column 2, flat steel tie bar 3, web 4 and concrete 5, and described circular core Columns 2 are evenly arranged in a font to form circular core column 2 walls, and square edge stiffening columns 1 are respectively provided at both ends of circular core column 2 walls. The square edge stiffening column 1 and circular core column 2 are both The webs 4 are welded to each other by groove penetration welding to form a straight wall, and a number of flat steel tie rods 3 are evenly arranged on the two outer surfaces of the wall, and the two ends of the flat steel tie rods 3 are respectively welded to the adjacent two sides. On the core column, it plays the role of constraining the outer concrete 5, improving the compressive pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com