Annular double-sided tooth high-speed miniaturized driving linear motion module

A technology of motion modules and double-sided teeth, which is applied in the direction of gear transmission, transmission, friction transmission, etc., can solve the problems of limiting motion accuracy and speed, large installation space, and easy wear of meshing transmission tooth surfaces, etc., to achieve Guaranteed stability and rigidity, low maintenance costs, and guaranteed transmission strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

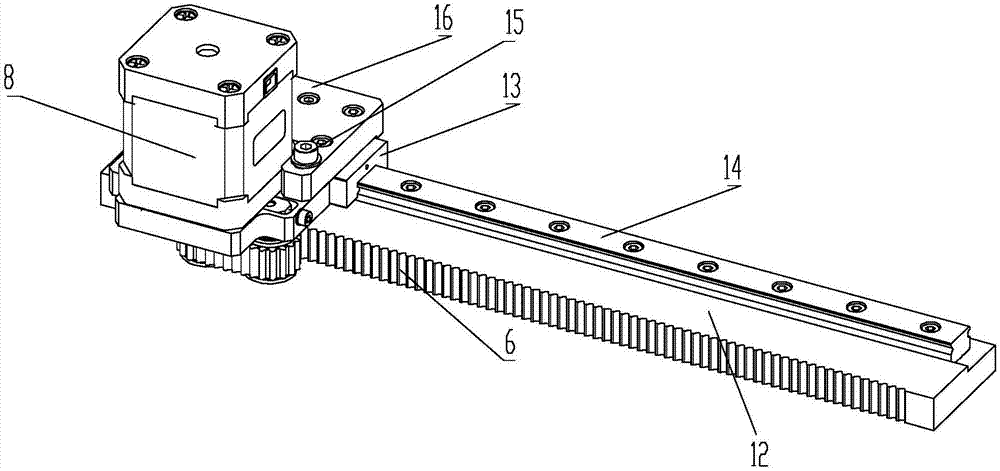

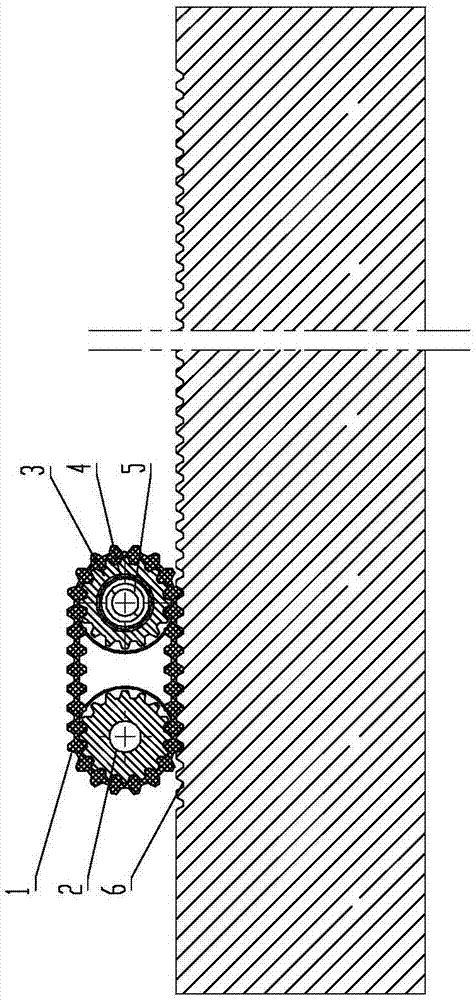

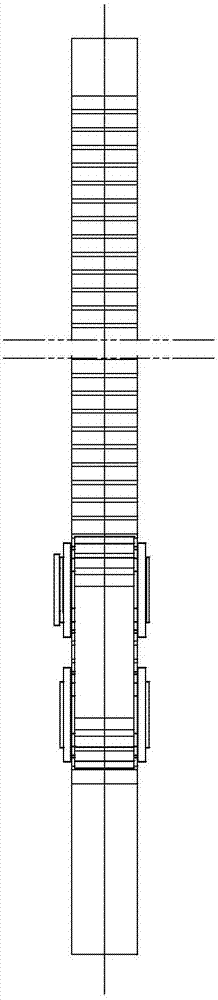

[0036] Such as Figure 1 to Figure 5 The circular double-sided gear high-speed miniaturized drive linear motion module shown includes a module base 12, a motor base 7, a drive motor 8, an annular double-sided tooth synchronous belt transmission mechanism and a guide mechanism, and the side surface of the module base 12 There is a linear synchronous rack and rack 6, the module base 12 and the synchronous rack and rack 6 are integrally processed and formed, the upper surface of the module base 12 is provided with a linear guide rail 14, the length direction of the linear guide rail 14 and the synchronous gear The length direction of the rack 6 is parallel, the motor base 7 is located above the module base 12, the drive motor 8 is installed on the motor base 7, and the ring-shaped double-sided tooth synchronous belt transmission mechanism is connected with the output shaft of the drive motor 8 and the motor base respectively. 7, and the annular double-sided tooth synchronous belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com