Colored light diffusion ink coating

A technology of colored light and ink, applied in coatings, anti-corrosion coatings, etc., can solve the problems of easy scratching of coatings, uneven and soft light intensity, glare of light, etc., and achieve good insulation, soft and beautiful light effects

Inactive Publication Date: 2021-06-22

宝盛材料科技(苏州)有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] 1. When the label is pasted on a strong light source such as LED, the naked eye can still see the dazzling light from the front of the light source, and the light intensity is not uniform and soft enough;

[0005] 2. Because the back of the label should be attached to the light source, the ink needs to be printed on the outer surface of the product, but the use of nano light guide powder in the ink often makes the coating easy to scratch;

[0006] 3. The requirement for the FU value of the ink surface cannot be higher than that of the label material itself

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

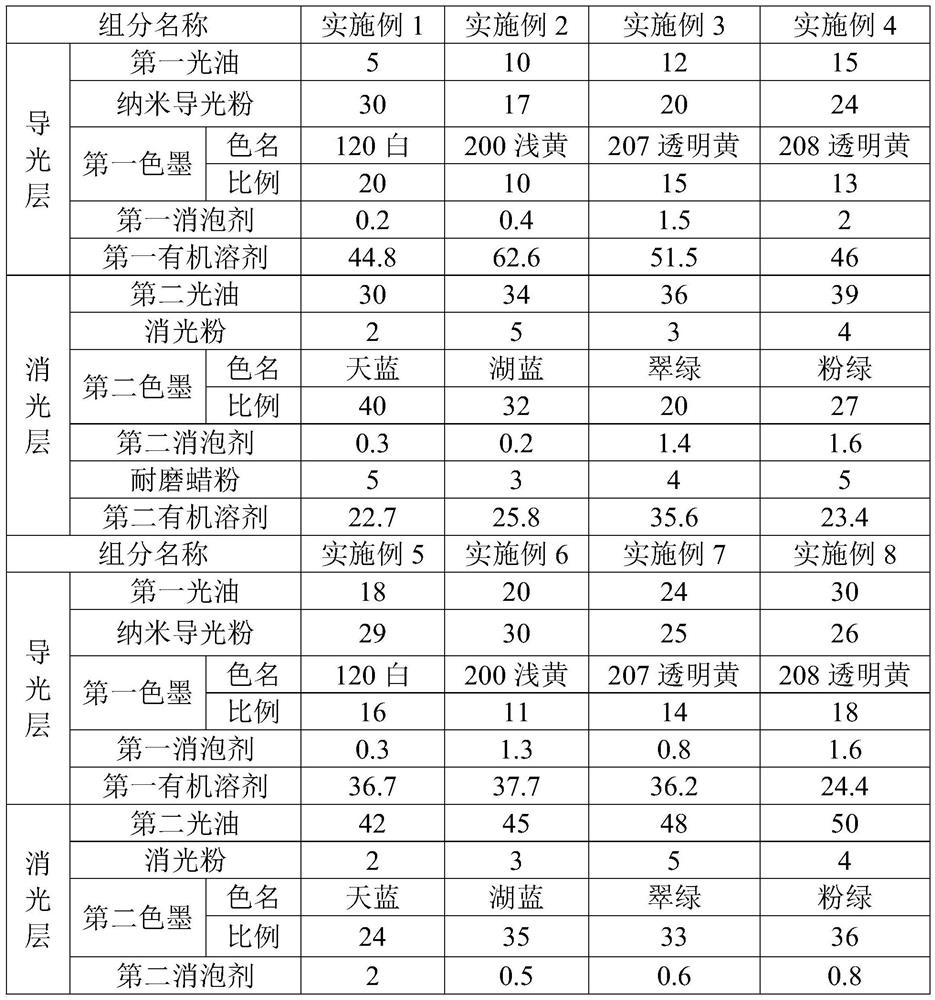

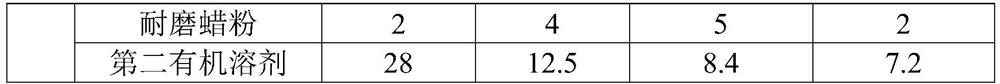

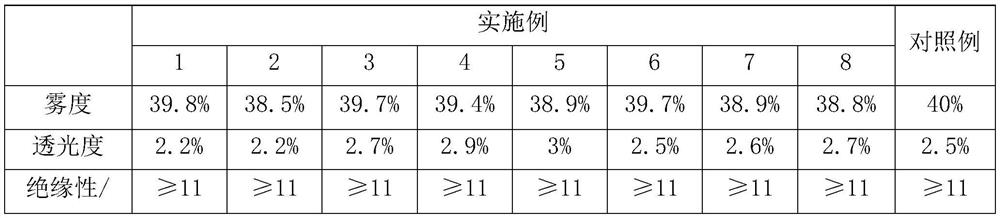

Embodiment 1~8

[0020] The ink of the color light diffusion ink coating light guiding layer and the matting layer of Example 1 to 8 is disposed according to the formulation of Table 1, and then the light guiding layer ink is applied to the surface of the substrate, 30 minutes at 70 ° C, and then The extinction layer ink was coated, cured at 70 ° C for 30 minutes.

[0021] Table 1: Unit: wt%

[0022]

[0023]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of printing ink, and particularly relates to a colored light diffusion printing ink coating which comprises a light guide layer directly coated on the surface of a product and an extinction layer coated outside the light guide layer, and the light guide layer comprises the following components in percentage by mass: 5-30wt% of first gloss oil, 15-30wt% of nano light guide powder, 10-20wt% of first color ink, 0.2-2wt% of first defoaming agent and the balance of first organic solvent, and the matting layer comprises the following components in percentage by mass: 30-50wt% of second gloss oil, 2-5wt% of matting powder, 20-40wt% of second color ink, 0.2-2wt% of a second defoaming agent, 2-5wt% of wear-resistant wax powder and the balance of a second organic solvent. According to the invention, the transmission intensity of colored light is ensured, the light is softer and more beautiful, and the coating also has good insulation, wear resistance and corrosion resistance.

Description

Technical field [0001] The present invention relates to the field of ink techniques, and more particularly to a color light diffusion ink coating. Background technique [0002] Some of the surfaces of some PET / PC material labels require printing translucent fresh color inks that make the surface of the label both bright colors, but also make light through the label. [0003] The ink in the prior art often has the following shortcomings: [0004] 1. When the label is attached to the strong light source such as LED, the naked eye can still see the glare rays from the light source, and the light is not uniform and soft; [0005] 2. Because the back of the label should be attached to the light source, the ink needs to print the outer surface of the product, but the ink uses nano-light powder to make the coating easily scratch; [0006] 3. The requirements of the ink surface FU value cannot be higher than the label material itself. [0007] It is therefore necessary to develop a new...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D201/00C09D7/40C09D7/42C09D7/65C09D5/08C09D5/25

CPCC09D201/00C09D7/40C09D7/42C09D7/65C09D5/08C09D5/00

Inventor 吴继明单国建

Owner 宝盛材料科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com