Intrinsic safety and explosion isolation separated pneumatic valve positioner

A technology of pneumatic valves and positioners, applied in valve details, valve devices, valve housing structures, etc., can solve problems such as difficult installation, large volume, poor seismic performance, etc., to achieve enhanced reliability, convenient installation, and reduced The effect of volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

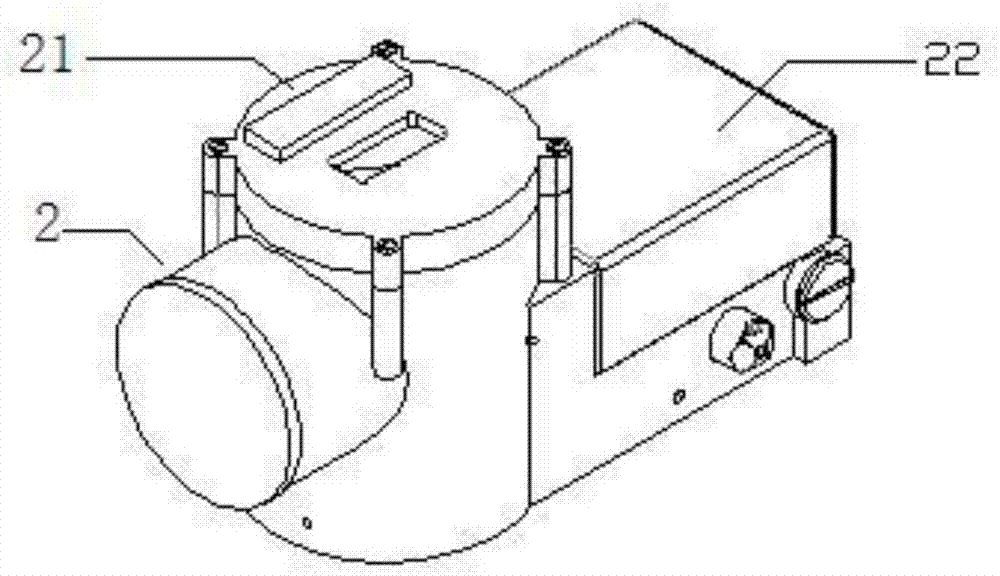

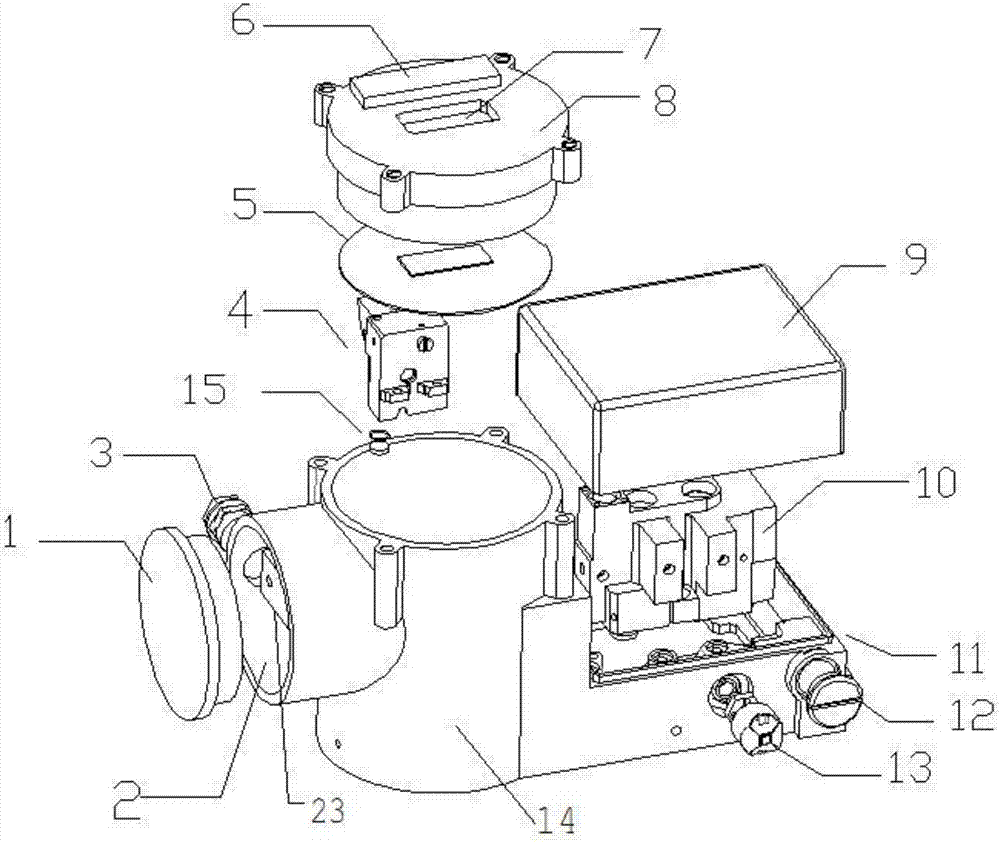

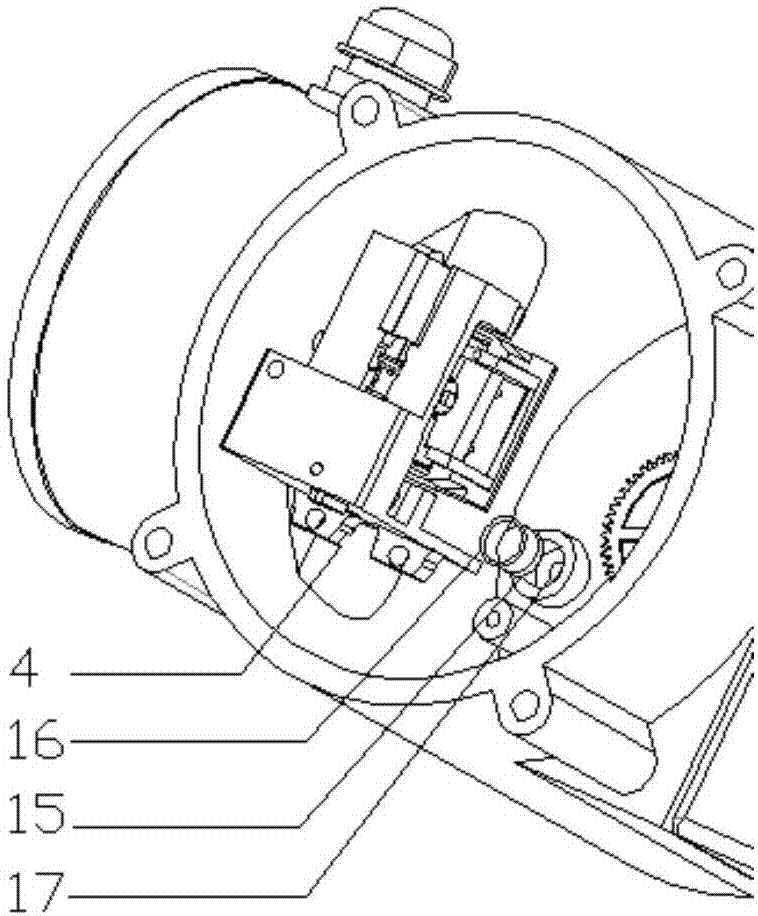

[0017] A pneumatic valve positioner with intrinsically safe and flameproof separation, comprising a flameproof chamber 21 and an intrinsically safe chamber 22. The explosion-proof chamber 21 includes a chamber body 14 , a cover body 8 sealing the chamber body 14 , and a wiring chamber 2 arranged on the side wall of the chamber body 14 . The cavity 14 is provided with a circuit board 5 , nozzle assembly 4 and sensor assemblies 18 , 19 , 20 , and the cover 8 is provided with an explosion-proof display window 7 , an explosion-proof button and a button cover 6 . The wiring cavity 2 is provided with lead terminals 23 , and the side wall of the wiring cavity 2 is provided with a flameproof cable interface 3 , and the wiring cavity 2 is sealed by the wiring cavity cover 1 .

[0018] Wherein, the wiring chamber 2 and the wiring chamber cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com