Infrared large-area-array multi-module automatic splicing mechanism

An automatic splicing, multi-module technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of high requirements for glue material coating process, scrapped focal plane of splicing, and high risk, and achieves high maintainability, low stress, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

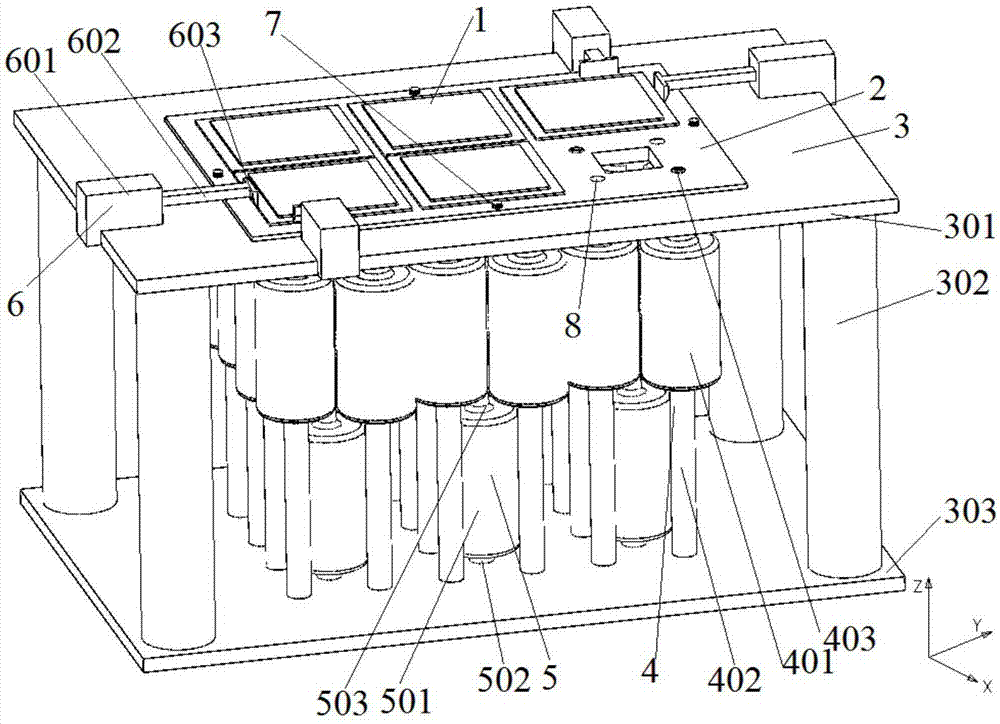

[0065] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

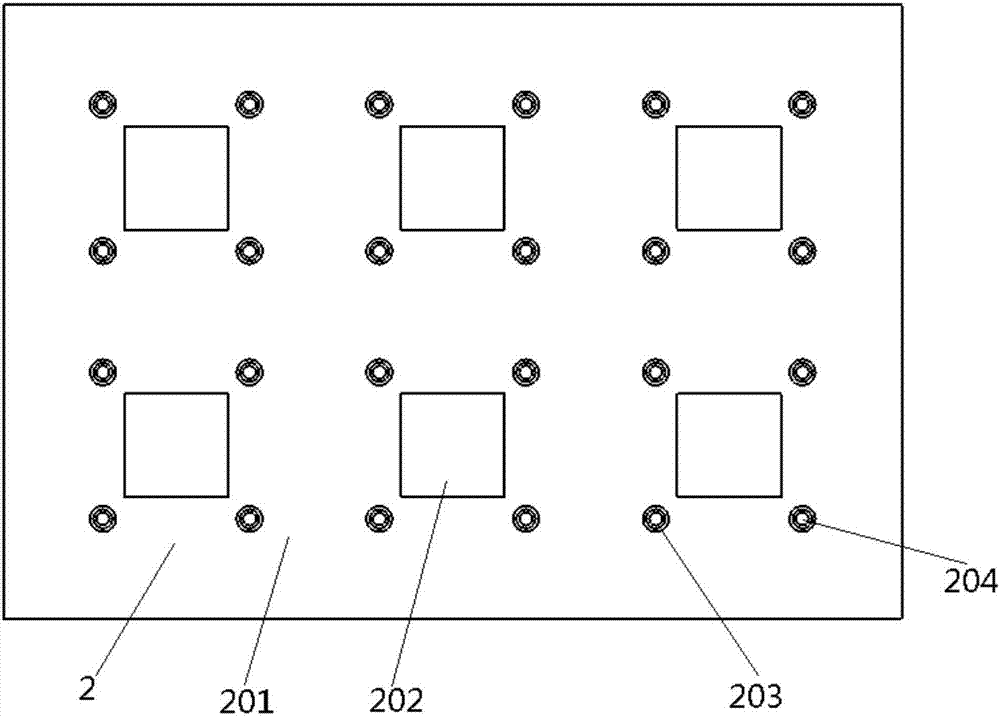

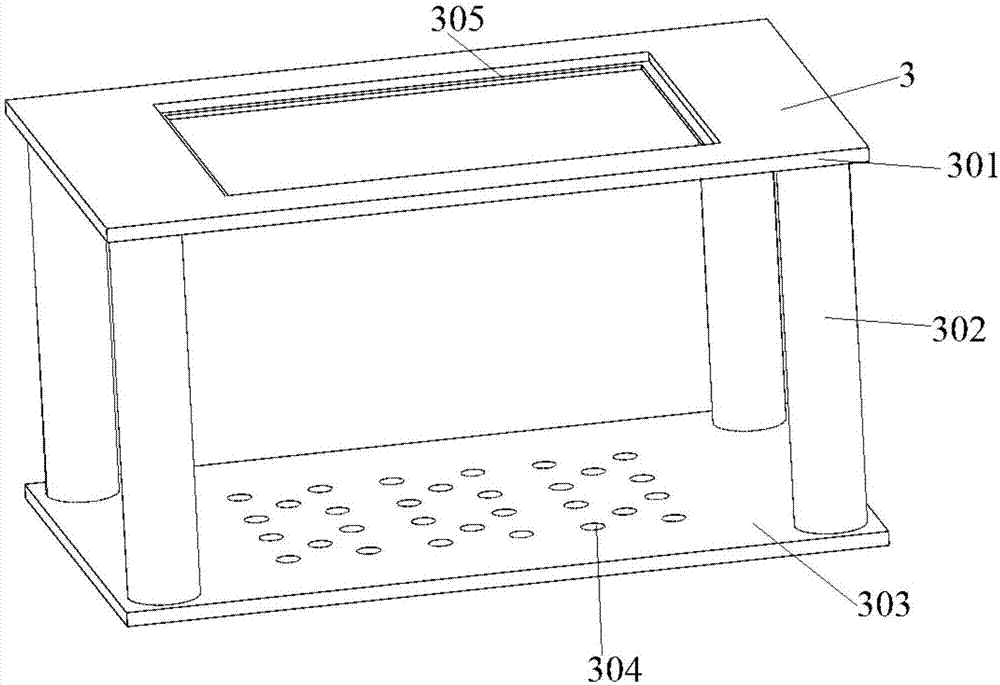

[0066] This embodiment is a large area array infrared detector for an aerospace pre-research project, which consists of four short-wave 1K×1K large-scale detector modules 1 spliced with high precision, and its mounting surface size is 22.1mm×28.3mm. required to follow figure 2 Splicing is carried out in the form of SiC / Al mounting substrate 201, and the centers of the modules are arranged in parallel to form a square. The three-dimensional spatial position relationship of the large area array detector module 1 is: the distance between the centers of the photosensitive surfaces satisfies 22.530mm±0.005mm in the X direction and 28.40mm in the Y direction. mm±0.005mm, the height difference in the Z direction between the photosensitive surfaces of the major area array detector modules 1 is ≤0.005mm, and the deviation between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com