Auxiliary device for form stripping of pervious concrete test block and form stripping method

A technology of permeable concrete and auxiliary device, which is applied in the directions of measuring device, preparation and sampling of test samples, can solve problems such as difficulty in demoulding of permeable concrete test blocks, and achieve the effect of quick demoulding and eliminating adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

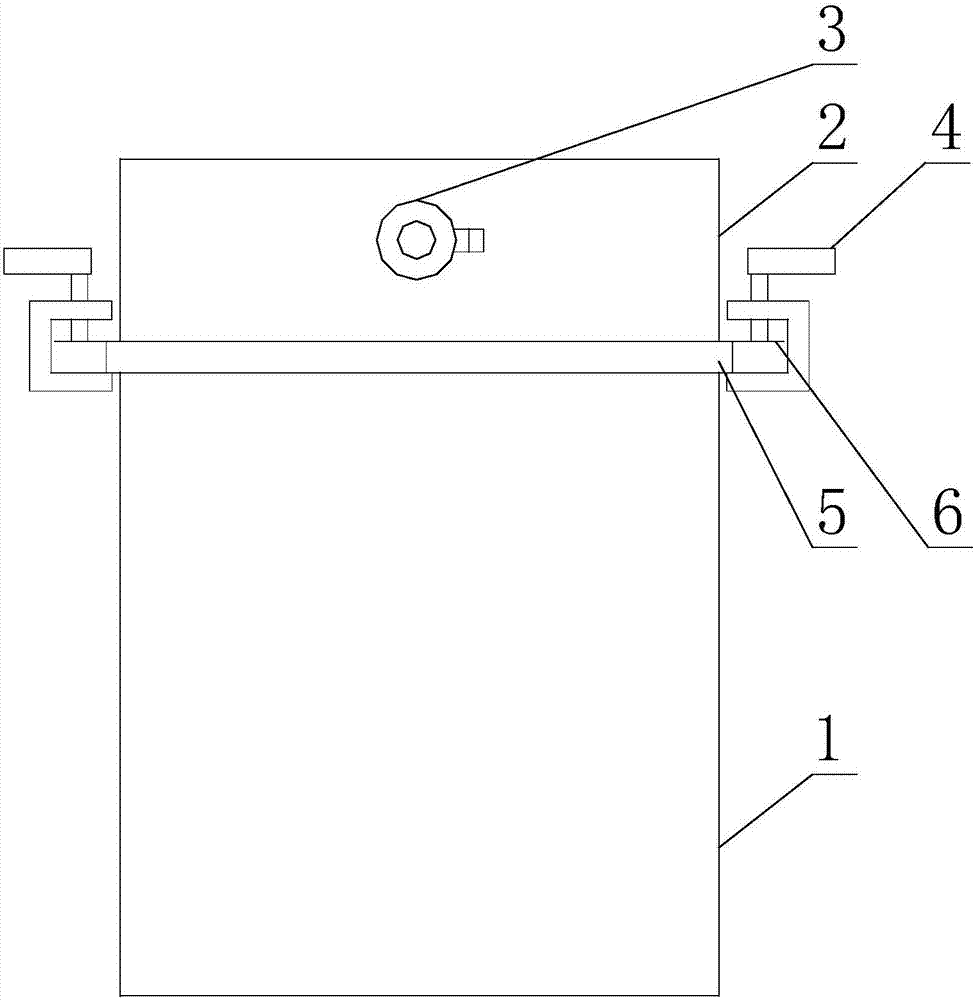

[0036] Such as figure 1 As shown, an auxiliary device for removing the formwork of a permeable concrete test block, including a cover body 2, a sealing strip 5 and a connecting device 4;

[0037] The cover 2 is a box-like structure with an opening at the lower end;

[0038] The opening at the lower end of the cover body 2 is used to dock with the opening at the upper end of the test mold 1, and the sealing strip 5 is annular, and the sealing strip 5 is used as a seal between the above two openings;

[0039] The connecting device 4 is used as a connecting piece between the cover body 2 and the test mold 1 when the above two openings are docked.

[0040] Permeable concrete is different from traditional concrete. Because of the pores between its aggregates, when demolding pervious concrete test blocks, it is impossible to use an air compressor to demolish pervious concrete like ordinary concrete: ordinary concrete is demolished using an air compressor. The principle of the mold i...

Embodiment 2

[0046] Such as figure 1 As shown, this embodiment is further limited on the basis of embodiment 1: after the demoulding is completed by compressed air, in order to realize the rapid pressure relief of the connecting body, it also includes a pressure relief valve arranged on the cover body 2 The pressure relief hole communicates with the inner and outer sides of the cover body 2, and the pressure relief hole is used to connect the pressure relief valve 3. In this solution, a pressure relief hole is provided on the cover body 2, and the pressure relief hole can also be used to repeatedly inflate and deflate the connecting body, so that the permeable concrete and Separation of trial mold 1. The above method of repeatedly inflating and deflating the connecting body is especially suitable for the working conditions where the test mold 1 has a small amount of expansion when it is subjected to internal pressure, such as the test mold 1 is a metal test mold 1, or the test mold 1 itse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com