A Method for Preserving Skipjack Meat by Coupling Application of Ultrahigh Pressure and ε-Polylysine

A technology of polylysine and skipjack fish meat, which is applied in the preservation of meat/fish with coating protection layer, ultra-high pressure food processing, application, etc., can solve the problem of broad-spectrum killing of harmful microorganisms and accumulation of metmyoglobin , fresh-keeping methods and other problems, to achieve the effect of reducing the rate of deterioration, inhibiting growth and reproduction, and prolonging the effective period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

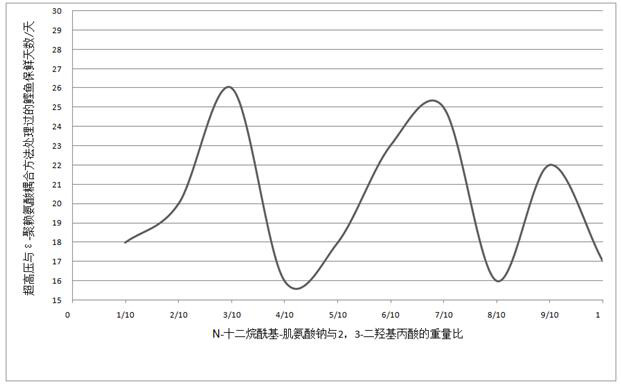

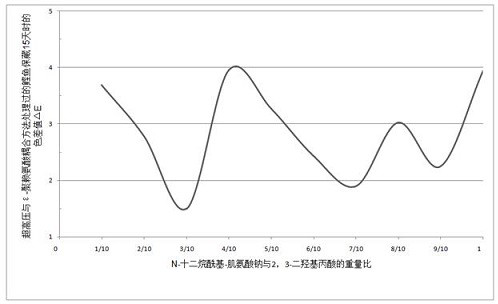

Image

Examples

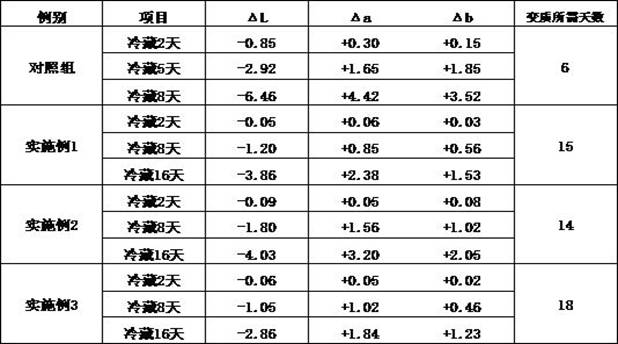

Embodiment 1

[0022] A method for preserving skipjack flesh by coupled application of ultrahigh pressure and ε-polylysine, comprising the following steps:

[0023] 1) Take the frozen skipjack and thaw it quickly with 8°C running water, remove the tail, fins, viscera and other impurities, cut it into fish pieces of 4.0cm×2.5cm×1.0cm, wrap it in plastic wrap and freeze it at low temperature; put the skipjack Cutting the fish into small pieces is helpful for the penetration of antibacterial liquid and improving the preservation effect; 2) Accurately weigh 0.050 parts of curcumin and completely dissolve it in 15 parts of absolute ethanol, and weigh 0.060 parts of ε-polylysine, 0.006 1 part of natamycin, 0.100 part of kojic acid, 0.002 part of VC, and 0.003 part of VE were dissolved in 100 parts of distilled water under stirring, and the ethanol solution of curcumin was slowly added to the aqueous solution, and stirred until it was stable and uniform to obtain a mixed antibacterial solution; The...

Embodiment 2

[0025] A method for preserving skipjack flesh by coupled application of ultrahigh pressure and ε-polylysine, comprising the following steps:

[0026] 1) Pretreatment: Take the frozen skipjack and thaw it quickly with running water at 10°C, remove the tail, fins, internal organs and other impurities, cut it into fish pieces of 5.0cm×3.0cm×1.0cm, wrap it in plastic wrap and store it in a low temperature freezer ;Cut the bonito meat into small pieces to help the penetration of the antibacterial solution and improve the preservation effect;

[0027] 2) Soaking: Accurately weigh 0.055 parts of curcumin, 0.016 parts of L-(+)-2,3-dihydroxypropionic acid, 0.004 parts of L-(-)-2,3-dihydroxypropionic acid and completely dissolve in 16 parts In absolute ethanol, weigh 0.065 parts of ε-polylysine, 0.007 parts of natamycin, 0.120 parts of kojic acid, 0.003 parts of VC, and 0.004 parts of VE, and dissolve them in 150 parts of distilled water under stirring. Slowly add the ethanol solution ...

Embodiment 3

[0031] A method for preserving skipjack fish meat by coupled application of ultrahigh pressure and ε-polylysine, comprising: pretreatment, soaking, ultrahigh pressure treatment, and preservation, specifically including the following steps:

[0032] Pretreatment: Take the frozen skipjack tuna and thaw it quickly with running water at 10°C, remove impurities such as the tail, fins, and internal organs, and then cut it into fish pieces of 4.0cm×3.0cm×1.0cm, wrap it in plastic wrap and store it in a low temperature freezer; Cutting bonito meat into small pieces helps the penetration of the antibacterial liquid and improves the freshness preservation effect;

[0033] Soaking: Accurately weigh 0.050 parts of curcumin complete, 0.02 parts of L-(+)-2,3-dihydroxypropionic acid, 0.005 parts of L-(-)-2,3-dihydroxypropionic acid dissolved in 15 parts of anhydrous In ethanol, weigh 0.060 parts of ε-polylysine, 0.006 parts of natamycin, 0.120 parts of kojic acid, 0.003 parts of VC, 0.004 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com