A device and method for on-line cleaning of cracks at corners of hot billets

A corner crack and cleaning method technology, which is applied in the field of continuous casting production, can solve problems such as inability to clean up, and achieve the effects of not occupying land resources, saving a lot of energy, and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

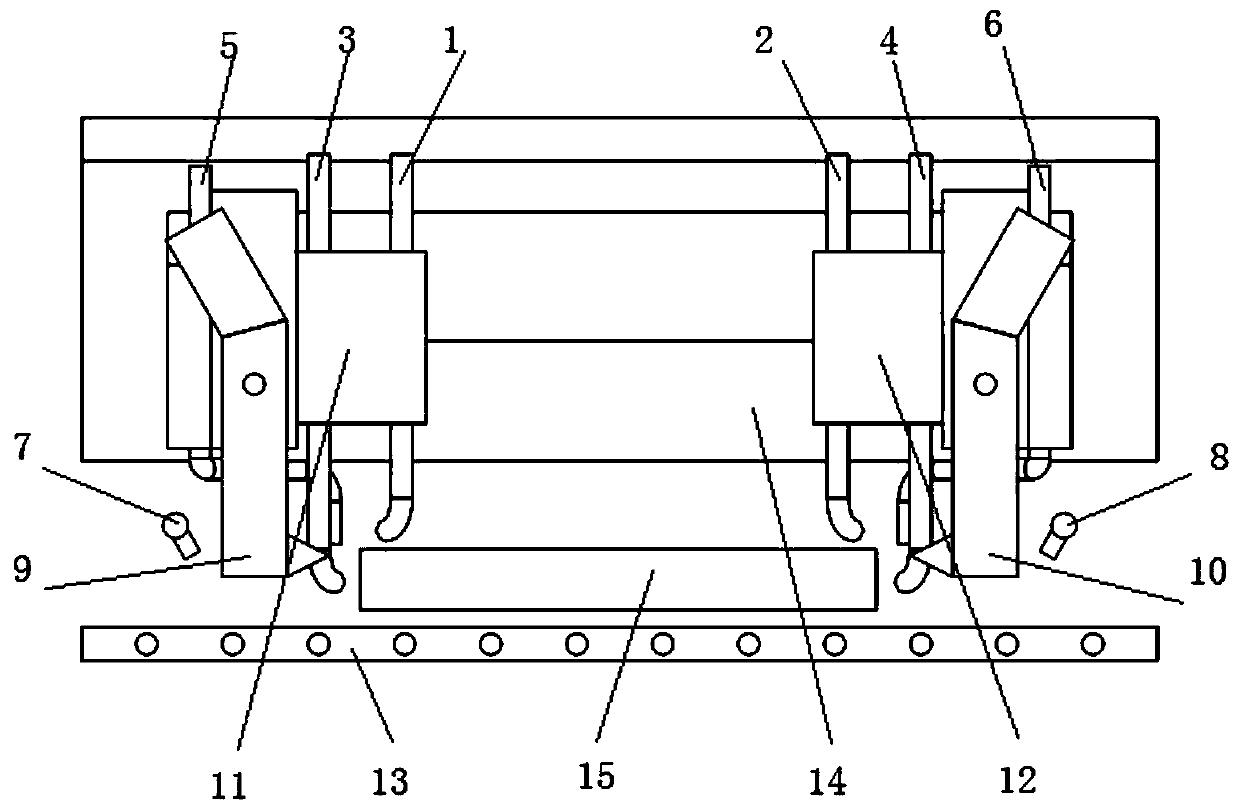

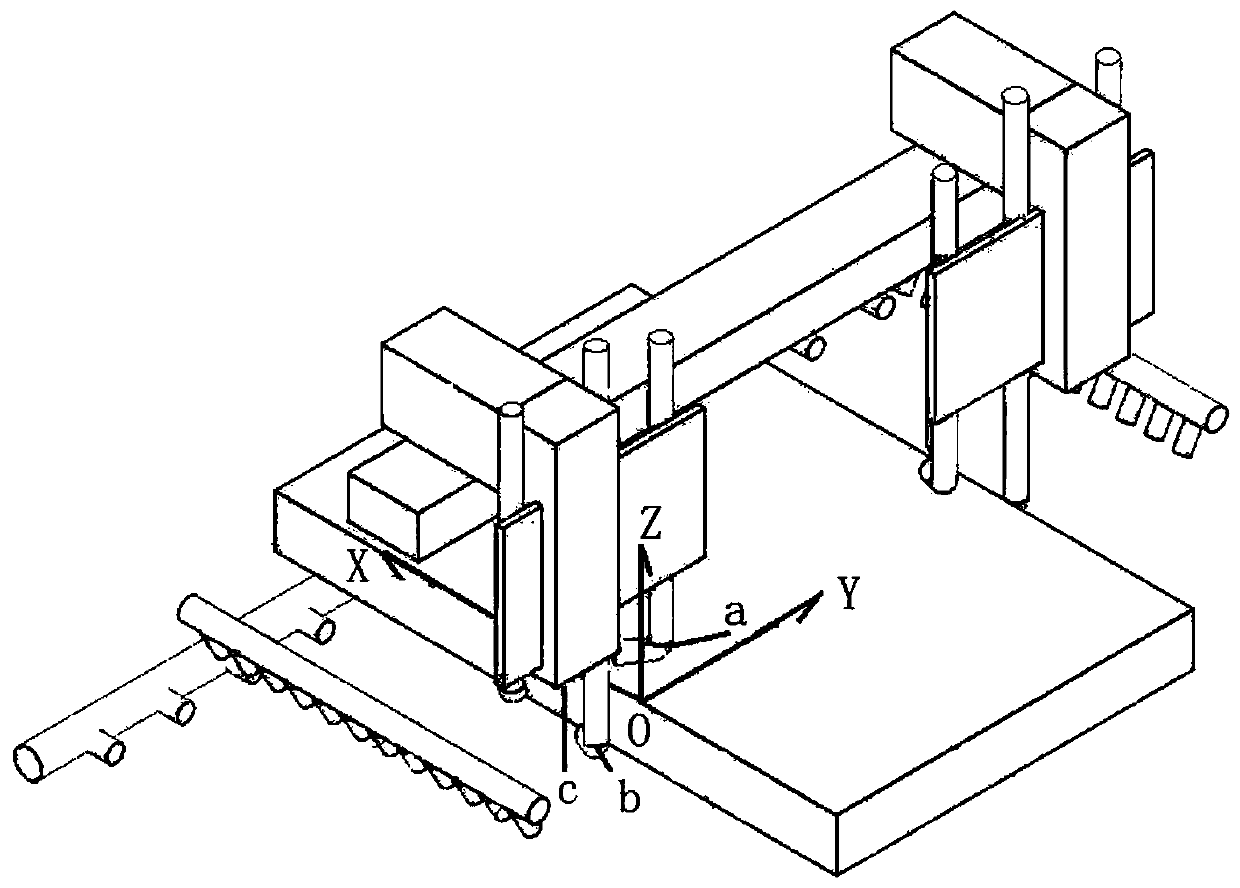

[0039] Such as figure 1 As shown, a hot billet corner crack online cleaning device according to the present invention is arranged between the segment of the continuous casting machine and the torch cutter, and includes inner arc cleaning guns 1, 2, outer arc cleaning guns 3, 4, Side slag treatment water guns 5, 6, inner arc water curtains 7, 8; outer arc water curtains 13; clamps 9, 10, trolleys 11, 12 and cart 14; cart 14 spans above the slab conveying roller table, The two trolleys 11 and 12 are respectively arranged on both sides of the cart 14 and can reciprocate along the direction perpendicular to the conveying direction of the slab 15; Billet 15, clamps 9, 10 clamp the billet 15 and drive the cart 14 to follow the billet 15; 2 sets of inner arc cleaning guns 1, 2, 2 sets of outer arc cleaning guns 3, 4 and 2 sets of side slag treatment On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com