A pcb board welding maintenance device

A technology for overhauling device and PCB board, applied in the field of electricity, can solve the problems of virtual welding between PCB board and electrical component pins, inconvenient collection and processing of solder blocks, inconvenient placement of electric soldering iron, etc., so as to improve cleanliness and maintenance efficiency. and its quality, the effect of preventing untimely processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

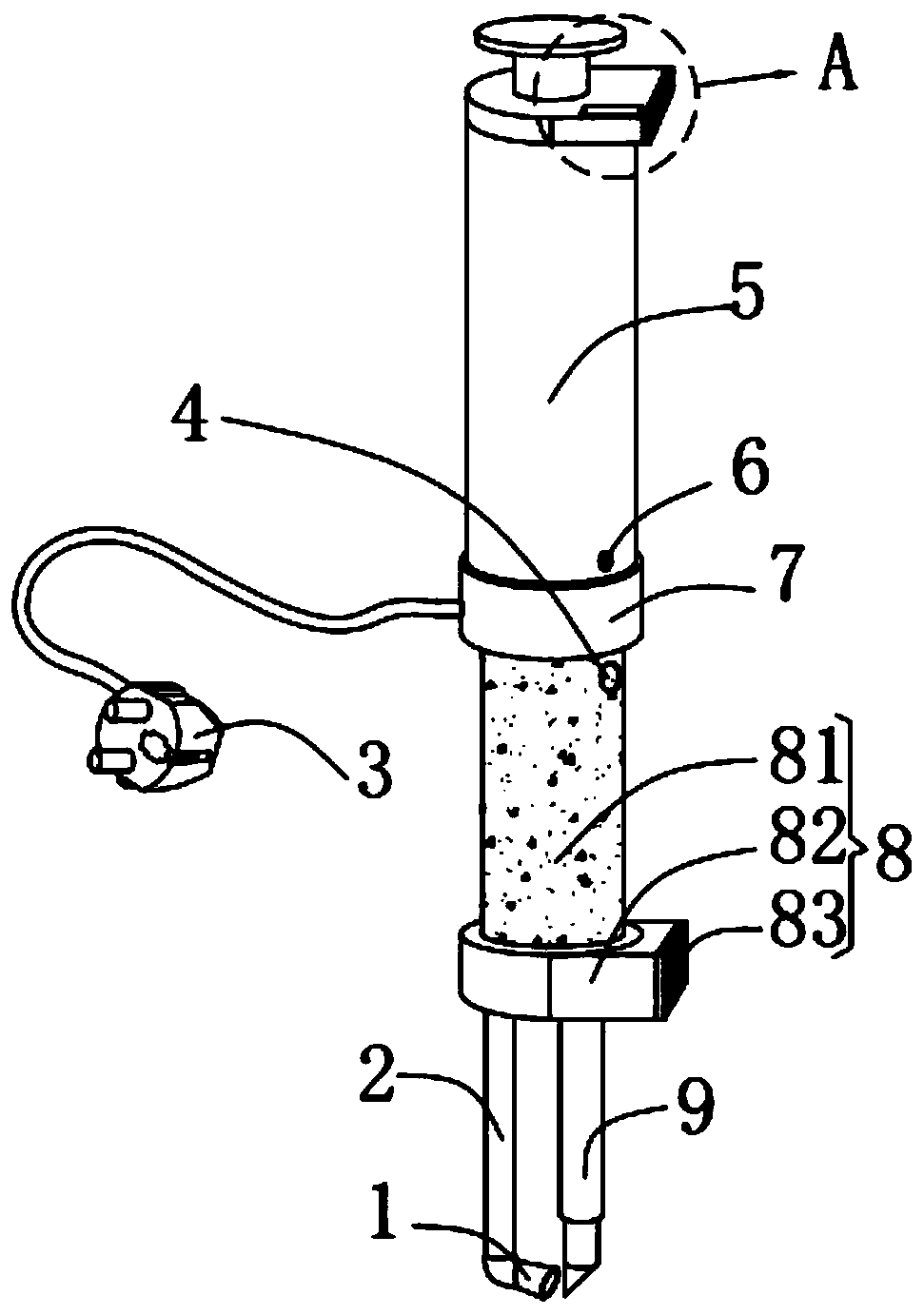

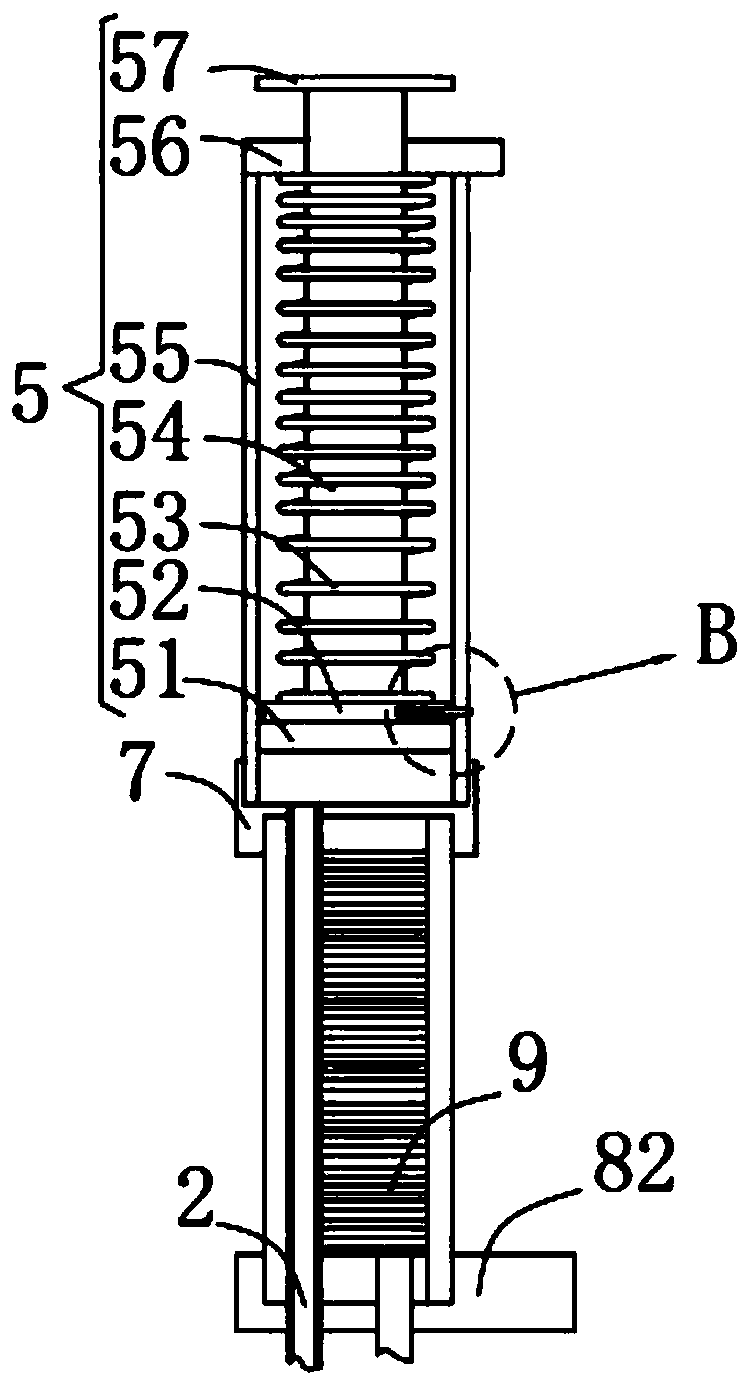

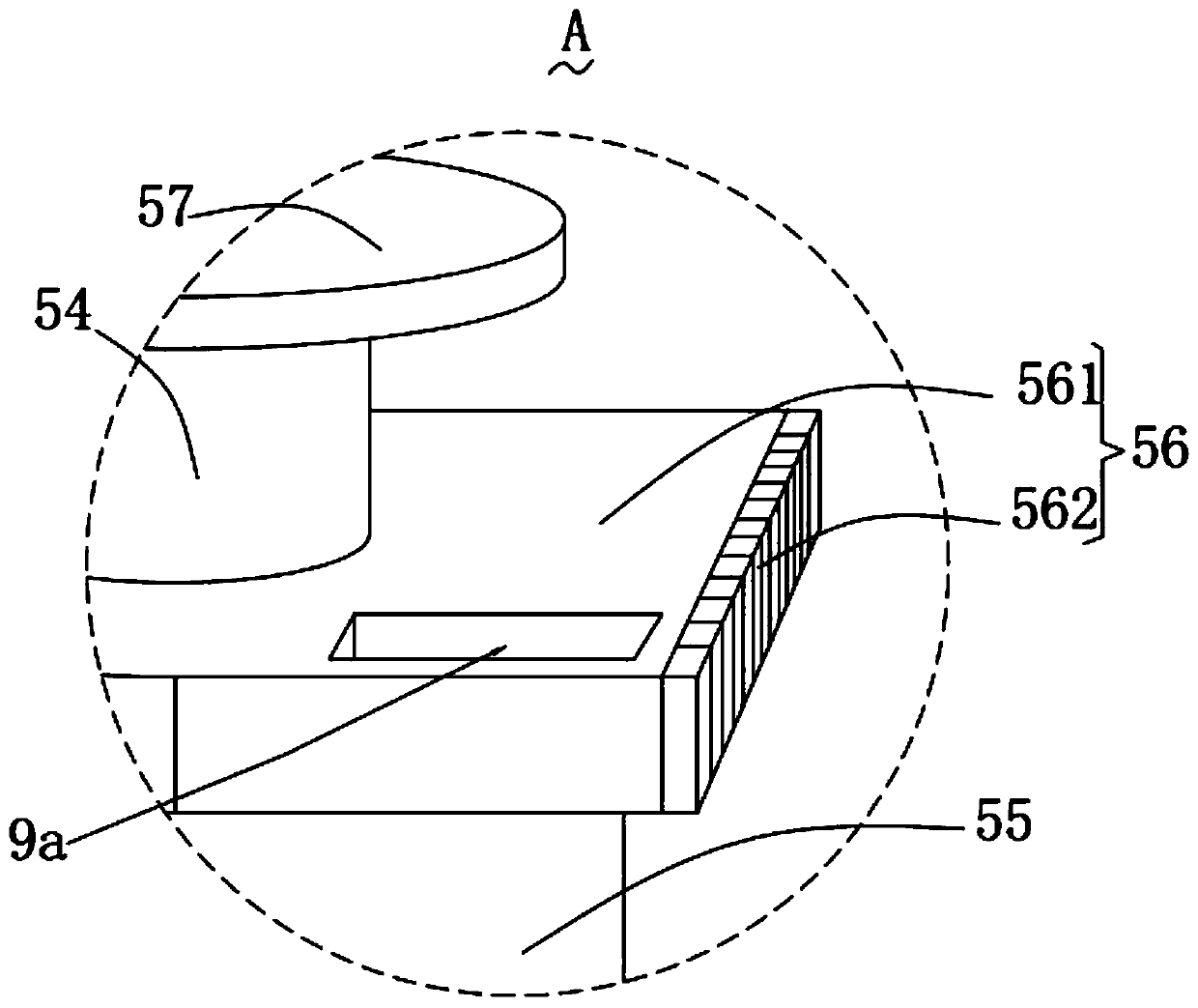

[0029] Such as figure 1As shown, a PCB board welding maintenance device according to Embodiment 1 of the present invention includes a chip removal structure 1, an air duct 2, a plug 3, a switch 4, a driving structure 5, a limiting structure 6, and a limiting sleeve 7 , a second fixed structure 8 and an electric soldering iron 9; one end of the air guide tube 2 is connected to the chip removal structure 1, and the other end of the air guide tube 2 extends through the second fixed structure 8 to the drive Structure 6; the electric soldering iron 9 is arranged on the second fixed structure 8, the electric soldering iron 9 is electrically connected to the switch 4 arranged on the second fixed structure 8, and the switch 4 is connected to the plug 3. Electrical connection; the limiting sleeve 7 is connected to the driving structure 5 and the second fixing structure 8; the limiting structure 6 penetrates through the driving structure 5.

[0030] Specifically, such as figure 1 As s...

Embodiment 2

[0036] Such as figure 1 As shown, a PCB board welding maintenance device according to the second embodiment of the present invention includes a chip removal structure 1, an air duct 2, a plug 3, a switch 4, a driving structure 5, a limiting structure 6, and a limiting sleeve 7 , a second fixed structure 8 and an electric soldering iron 9; one end of the air guide tube 2 is connected to the chip removal structure 1, and the other end of the air guide tube 2 extends through the second fixed structure 8 to the drive Structure 6; the electric soldering iron 9 is arranged on the second fixed structure 8, the electric soldering iron 9 is electrically connected to the switch 4 arranged on the second fixed structure 8, and the switch 4 is connected to the plug 3. Electrical connection; the limiting sleeve 7 is connected to the driving structure 5 and the second fixing structure 8; the limiting structure 6 penetrates through the driving structure 5.

[0037] Specifically, such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com