Three-jaw type follower rest special for turning large-pitch threaded rods

A technology with tool rest and large pitch, applied in the field of machining equipment, can solve the problems of increased vibration, large pitch of the screw with large pitch, affecting the machining accuracy and surface quality of the turning thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a detailed description of the technical features and usage methods of the present invention in conjunction with the accompanying drawings.

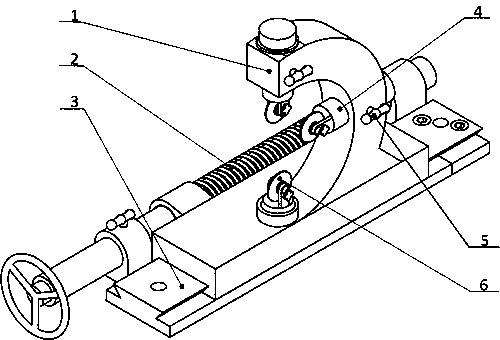

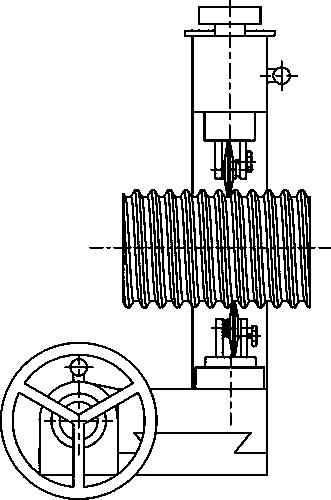

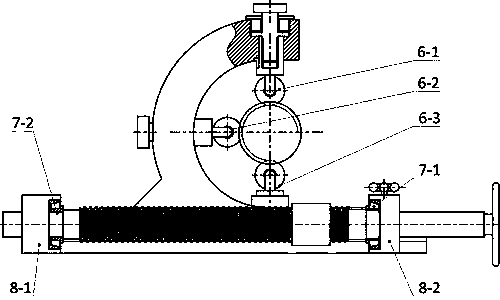

[0023] figure 1 It is a schematic diagram of the overall structure of a special three-jaw heel tool holder for turning large-pitch threaded screws according to the present invention, including a slidable heel tool holder base 3 and a driving device, a semicircular arc-shaped heel tool holder body 1 and an axial axis for centering. Adjustable support claws 6, the slidable heel rest base 3 is installed on the saddle of the machine tool slide box, moves with the slide box, on the slidable heel rest base there is a semicircular arc heel knife The moving track of the frame body is dovetail-shaped, and is precisely matched with the semicircular arc and the tool holder body, so that the semicircular arc and the tool holder body can only move laterally and cannot be separated, so as to achieve stability; On one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com