Sensorless mechanical arm collision detection method

A technology of collision detection and manipulators, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of increasing factory operating costs, inconvenience, false positives and false negatives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Embodiments of the present invention are described in detail below. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention. In addition, it should be noted that, for the convenience of description, only parts related to the present invention are shown in the drawings but not all content.

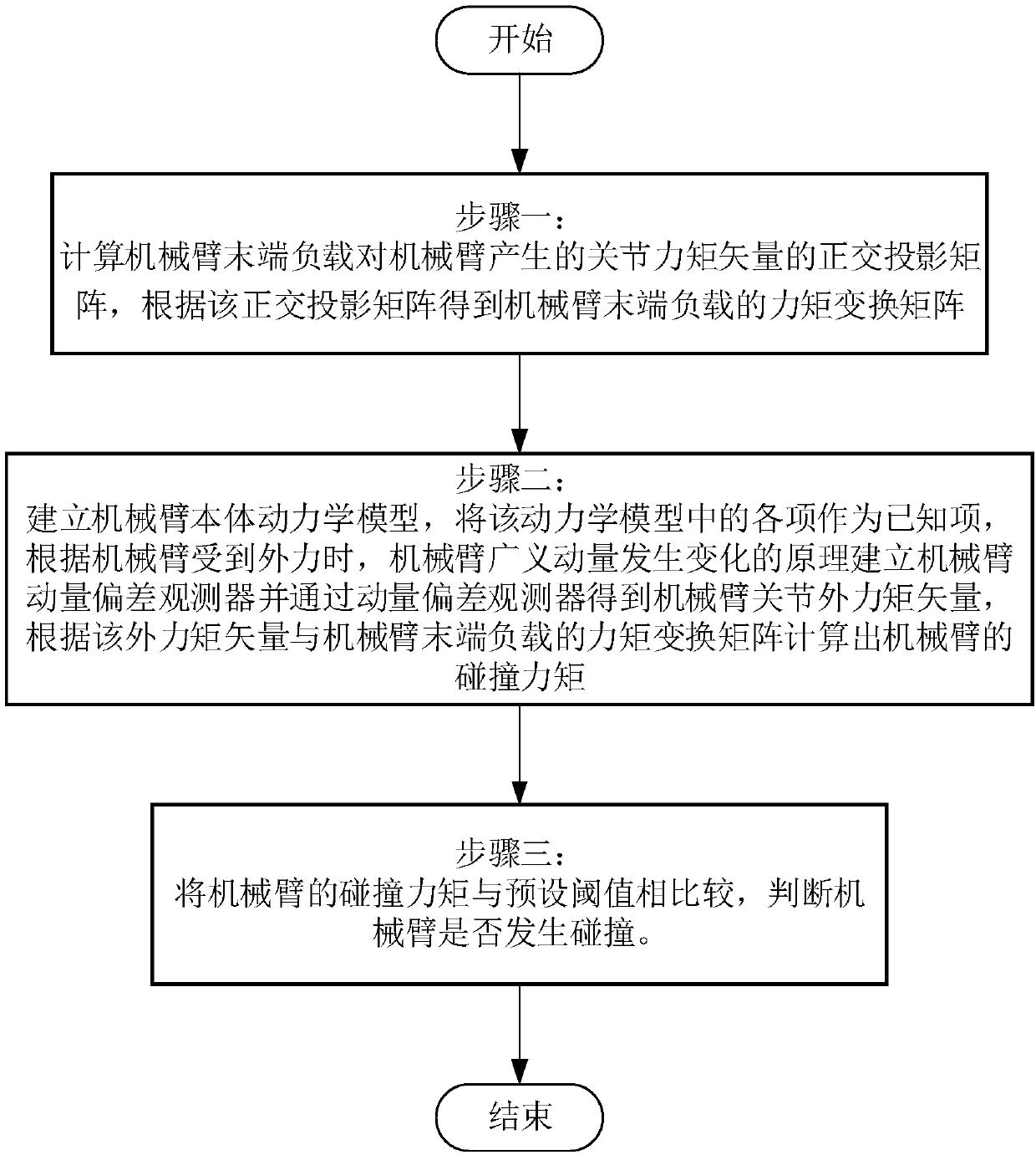

[0062] Such as figure 1 as shown, figure 1 It is a flowchart of a sensor-free robotic arm collision detection method in an embodiment of the present invention. The robotic arm body used in this specific embodiment is a seven-axis collaborative robot. The specific steps are as follows:

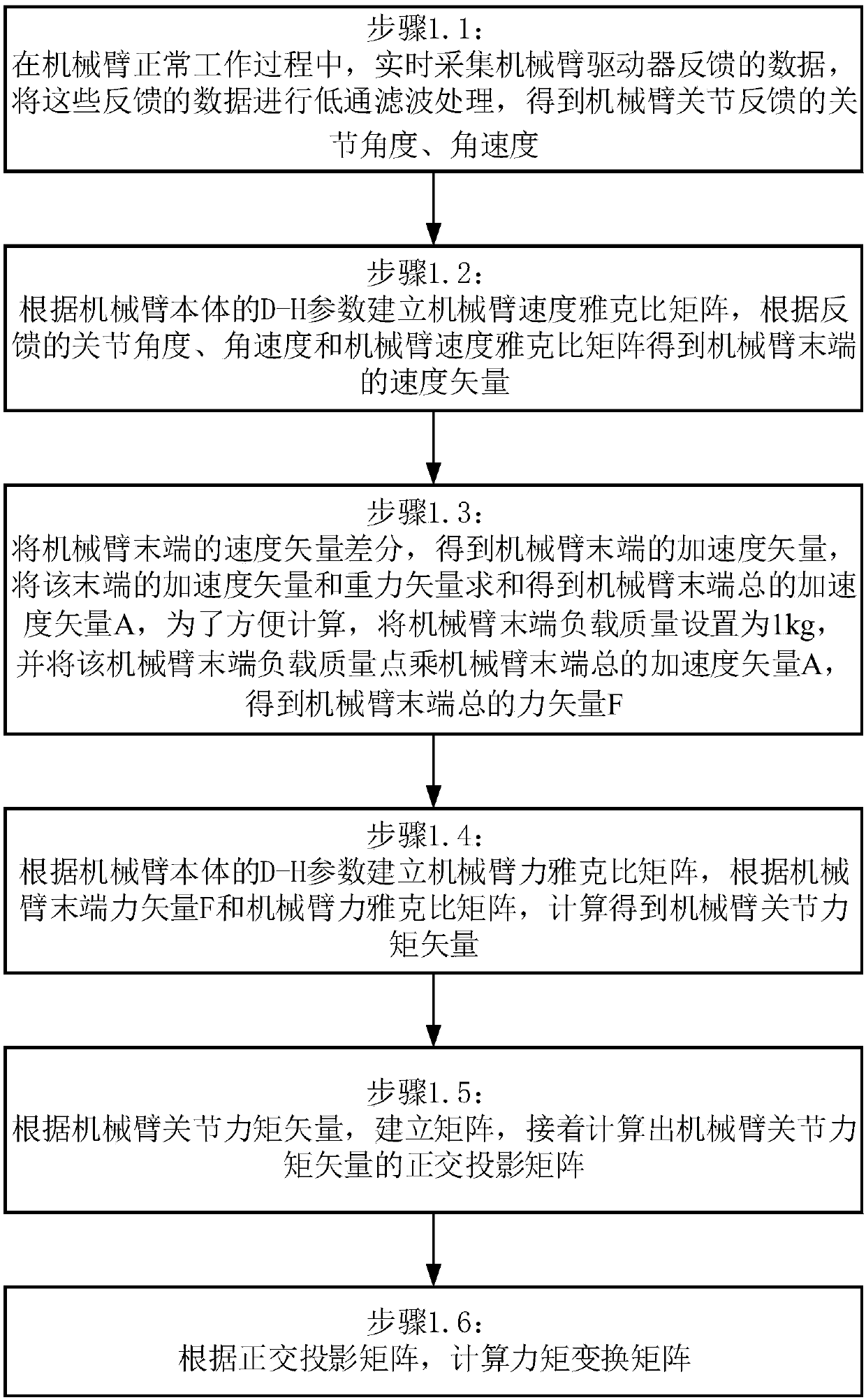

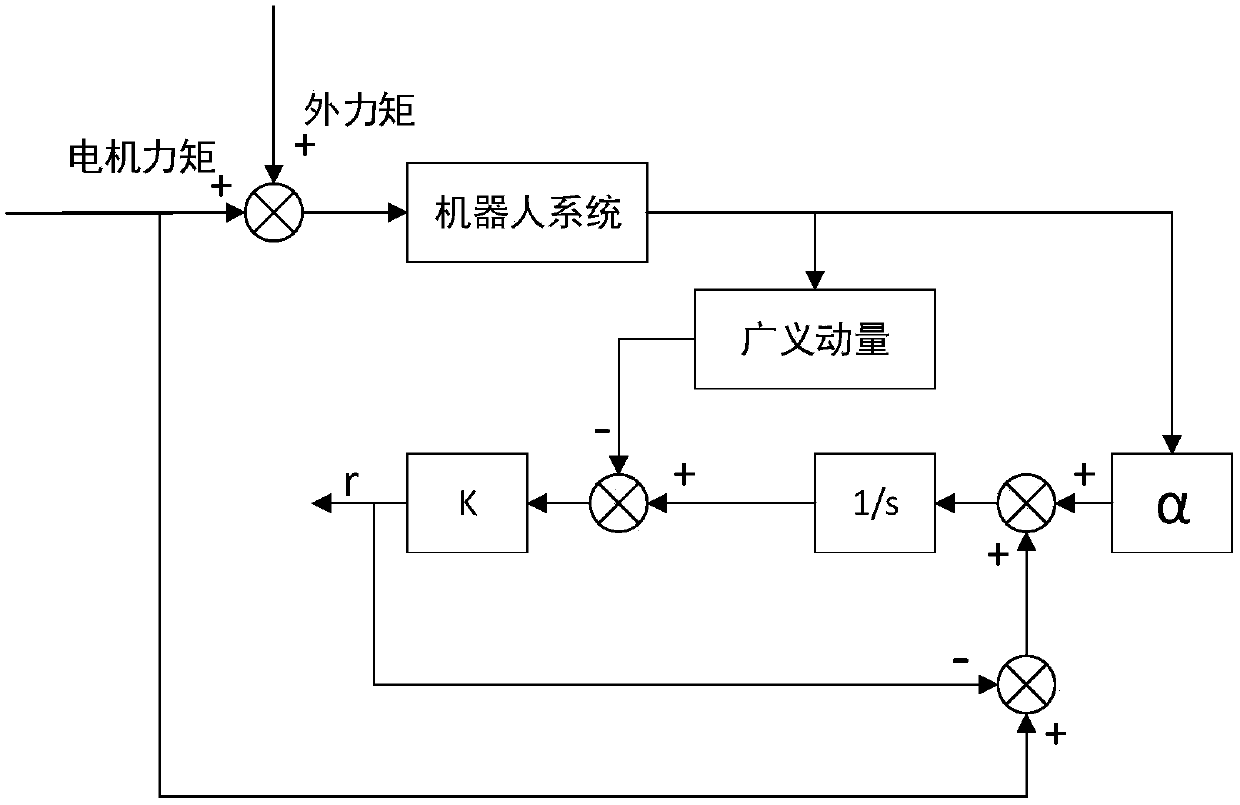

[0063] Step 1: Calculate the orthogonal projection matrix PF of the joint torque vector generated by the end load of the manipulator to the manipulator, and obtain the torque transformation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com