Peripheral surface contact torque sensor and the electric power-assisted vehicle

A pressure sensor and sensor technology, applied in the field of sensors, can solve problems such as difficulty in meeting market needs, inability to achieve self-sufficiency, complex structure, etc., and achieve the effects of compact structure, accurate measurement, and simple transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

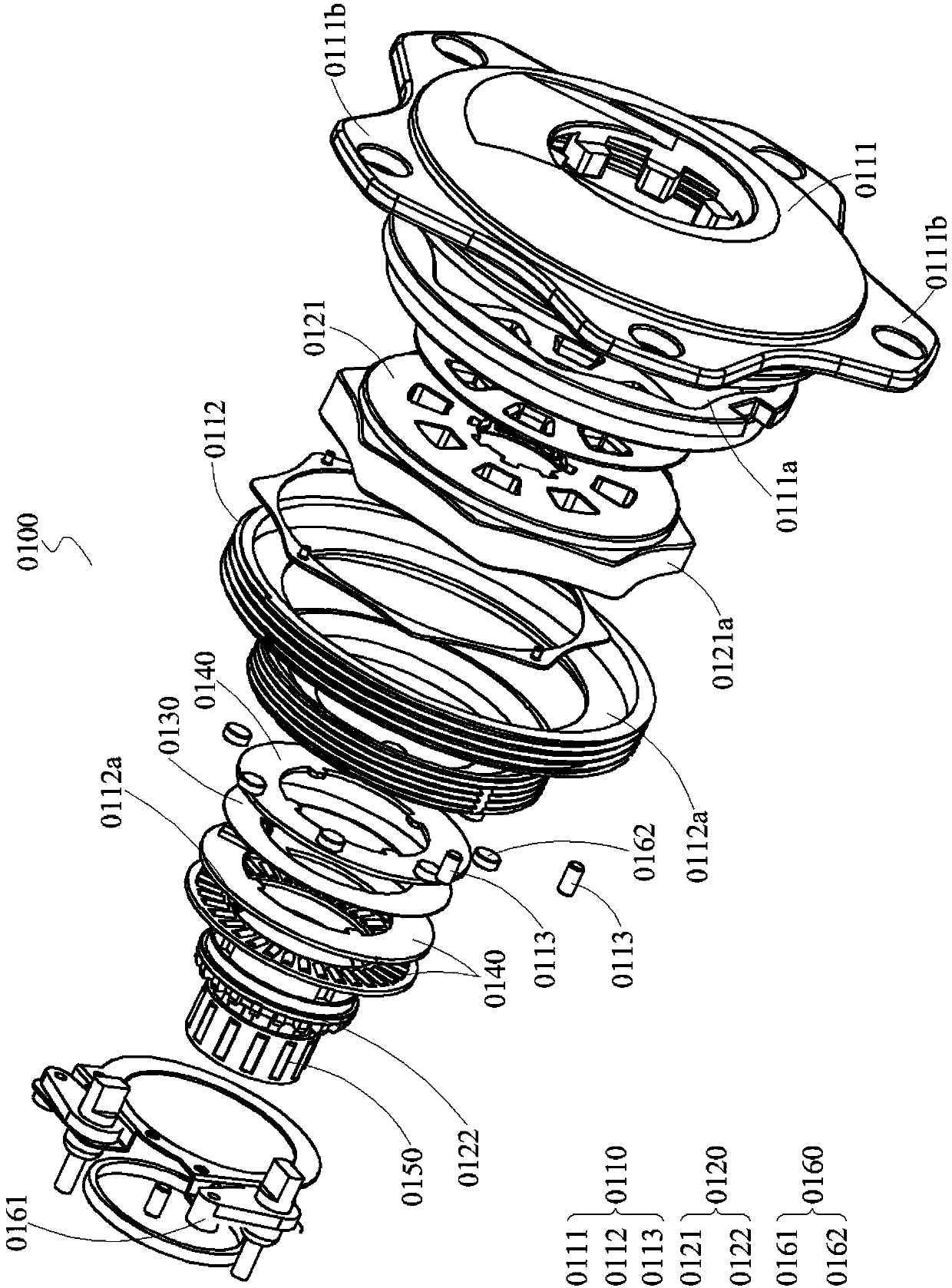

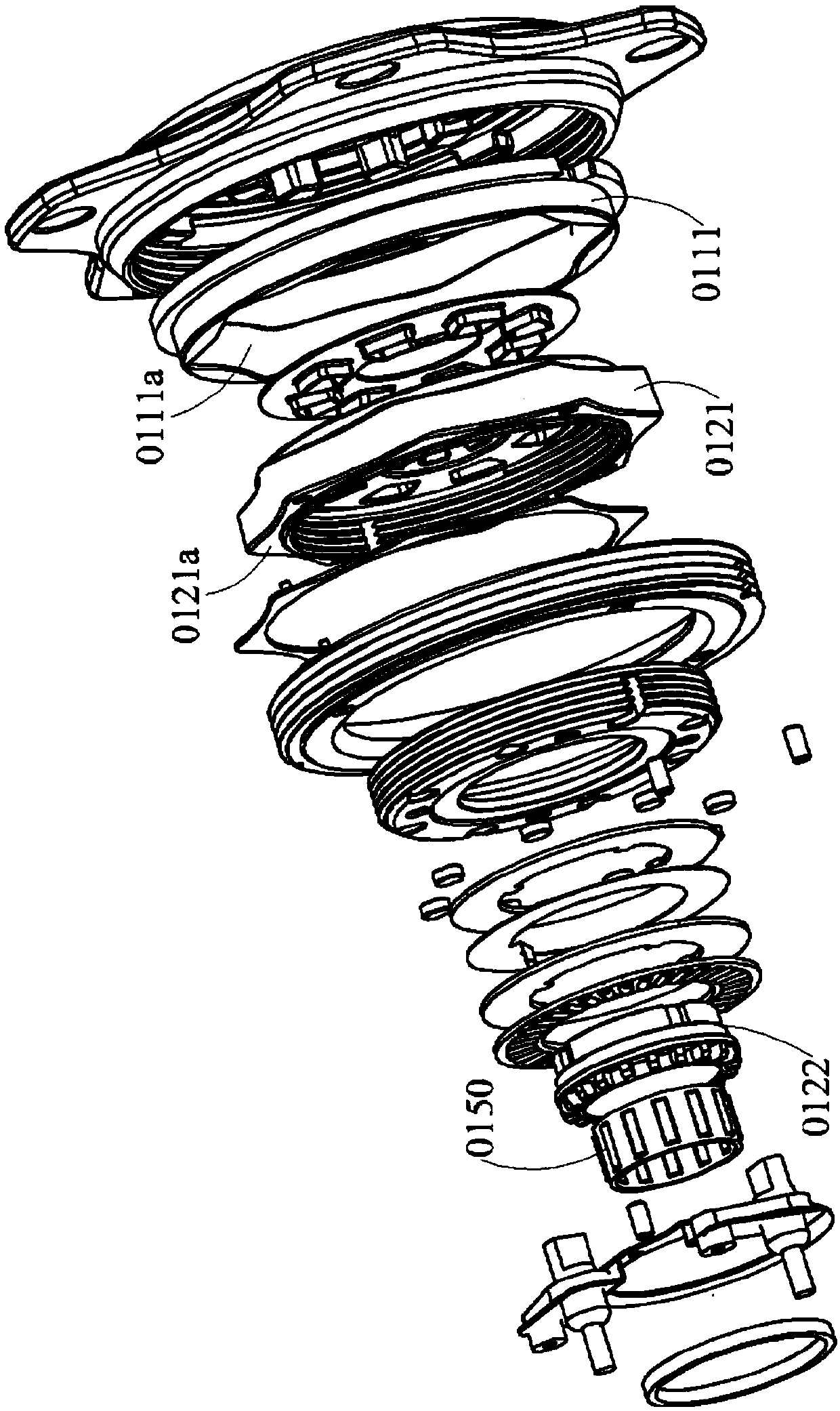

[0035] Please refer to Figure 1~2 , the present embodiment provides a peripheral surface contact torque sensor 0100, the peripheral surface contact torque sensor 0100 includes a body unit 0110, a torque input terminal 0120 and a pressure sensor 0130, to realize quick and accurate measurement of torque, with a compact structure , responsive, accurate measurement and other advantages. The main structure of the peripheral surface contact torque sensor 0100 will be introduced in detail below.

[0036] First of all, in this embodiment, the torque to be measured is input from the torque input terminal 0120, and is converted into an axial force by the peripheral surface contact between the torque input terminal 0120 and the body unit 0110, and then transmitted to the pressure sensor 0130. Realize inductive measurement.

[0037] The body unit 0110 includes a first active surface 0111a and a second active surface 0112a oppositely disposed. The first acting surface 0111a is used to ...

Embodiment 2

[0050] Please refer to Figure 1~2 , On the basis of Embodiment 1, this embodiment provides a peripheral surface contact torque sensor 0100 with an improved structure, and the improvement lies in the specific structure of the body unit 0110 . The structure of the body unit 0110 will be described in detail below, and the rest of the parts that have been described in Embodiment 1 will not be repeated here.

[0051] The body unit 0110 can adopt an integral molding structure, or a split splicing structure. Preferably, the body unit 0110 includes a fixed installation body 0111 and a press-fit cover 0112, the side of the installation body 0111 facing the torque input end 0120 has a first action surface 0111a, and the side of the press-fit cover 0112 facing the torque input end 0120 has a The second active surface 0112a.

[0052] Install the body 0111 and the press-fit cover 0112 by nailing, welding, etc., so that there is no relative movement between the two. Preferably, the inst...

Embodiment 3

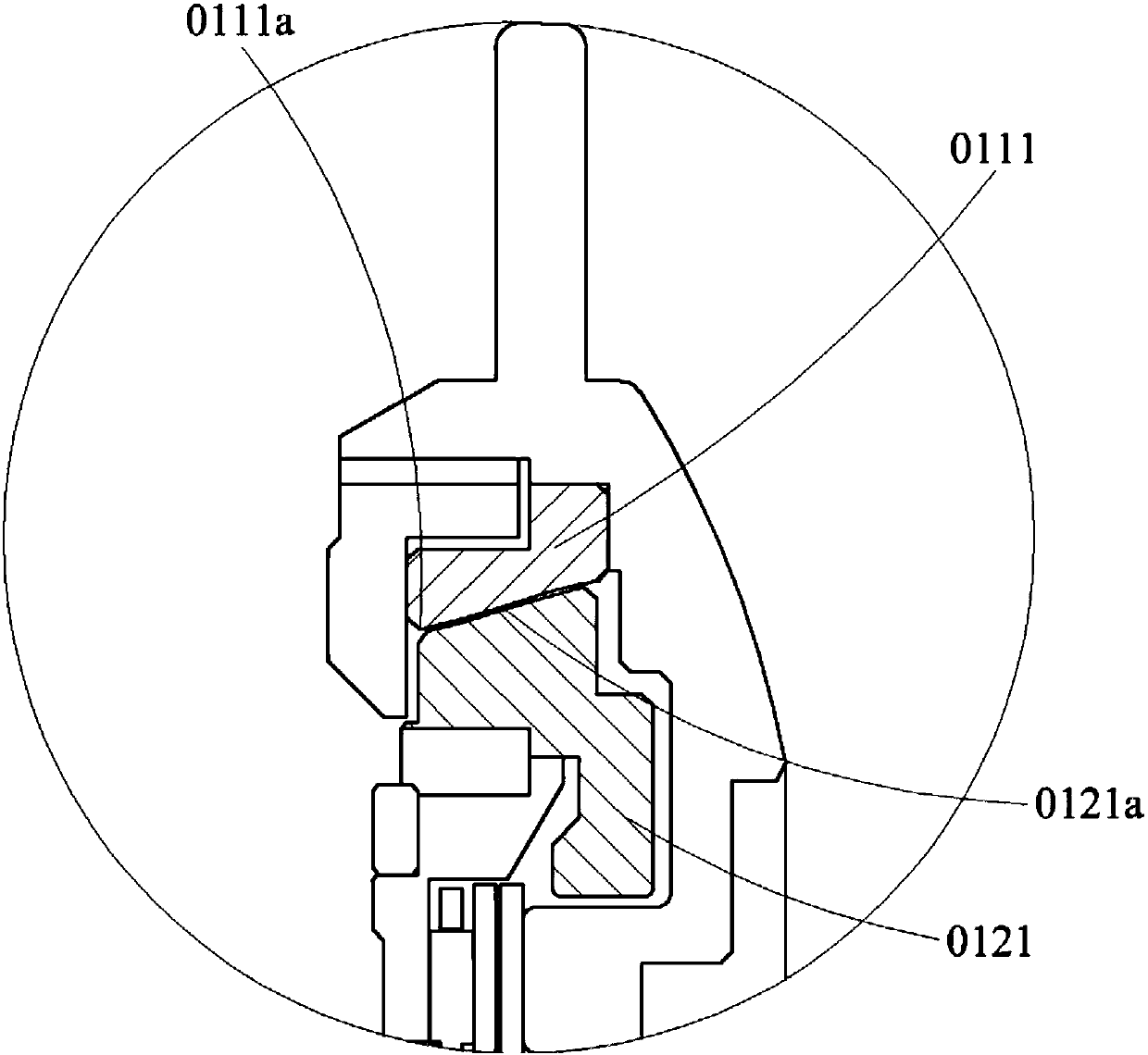

[0057] Please refer to Figure 1~2 , On the basis of Embodiment 1 or 2, this embodiment provides a peripheral surface contact torque sensor 0100 with an improved structure, and the improvement lies in the specific form of the peripheral surface contact. The structure of the peripheral surface contact will be described in detail below, and the other parts that have been described in Embodiment 1 or 2 will not be repeated here.

[0058] Preferably, the torque input end 0120 has a transmission curved surface 0121a on the peripheral side of one end facing the first acting surface 0111a, and the driving curved surface 0121a and the first acting surface 0111a have the same surface profile and form a peripheral surface contact engagement relationship. It should be understood that the so-called peripheral side of one end is not limited to the end of the axial outer contour of the torque input end 0120, but only refers to the outer peripheral surface of the exposed end directly facing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com