Automatic assembly machine for connector

A connector and assembly machine technology, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problems that the output and quality cannot meet customer requirements, reduce the market competitiveness of enterprises, and ensure product quality is difficult to achieve. The effect of good assembly quality, improved efficiency and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

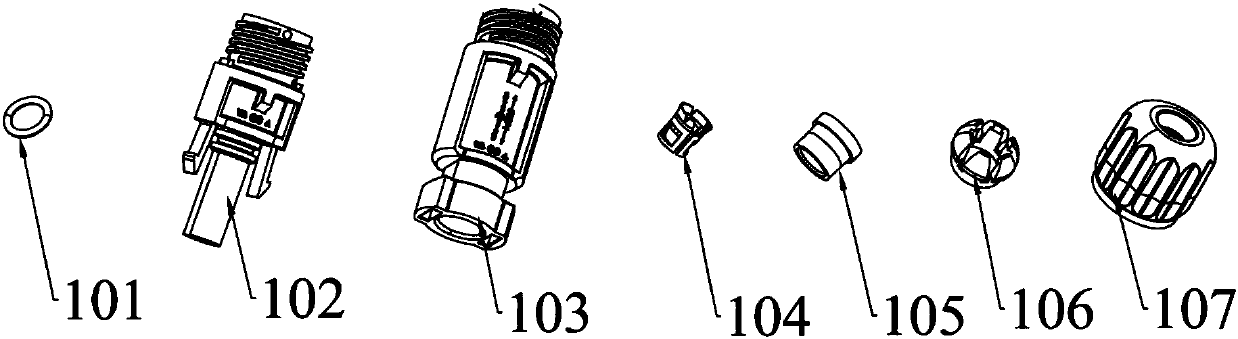

[0049] The connector provided by the present invention, such as figure 1 As shown, its main components include: sealing ring 101, connector positive pole 102, connector negative pole 103, stop ring 104, inner plug 105, turnbuckle 106 and nut 107, and the assembly sequence is: connector positive pole 102 and sealing ring After 101 is assembled, put the anti-retraction ring 104 into the card slot of the positive connector 103 and press it tightly. and tighten the cap 107; on the other side, install the anti-retraction ring 104 in the card slot of the negative pole of the connector 103, press it tightly, and then install the assembled inner plug flange, and then install the nut 107 on the screw port of the negative pole of the connector 103 and tighten; finally, the assembled connector positive pole 102 and the connector negative pole 103 are matched and connected to obtain a connector product. Therefore, after the sealing ring 101 is assembled on the positive electrode 102 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com