Laser-machining head and laser-machining machine comprising same

A laser processing head, laser technology, applied in manufacturing tools, laser welding equipment, metal processing equipment and other directions, can solve problems such as adverse observation accuracy and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

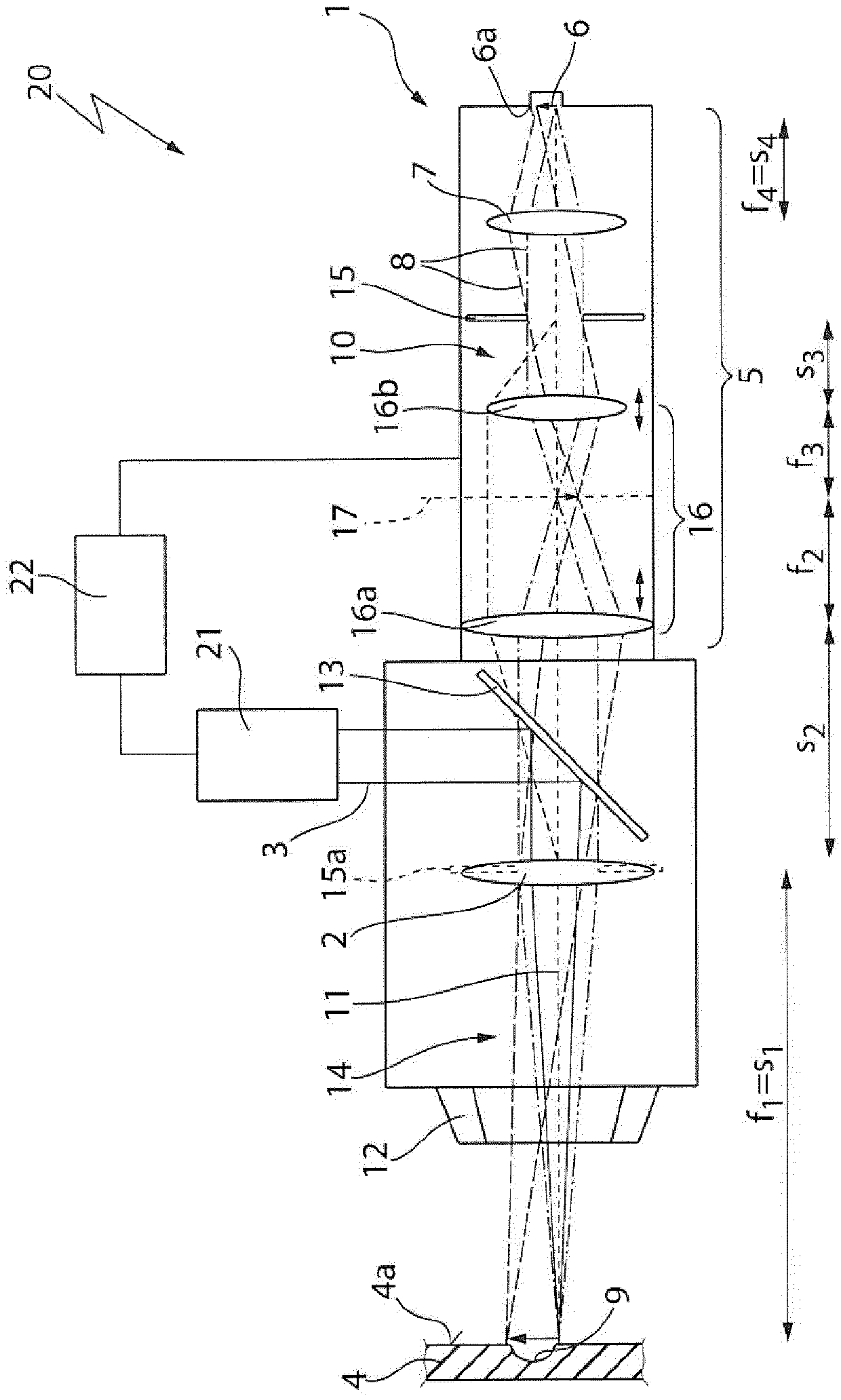

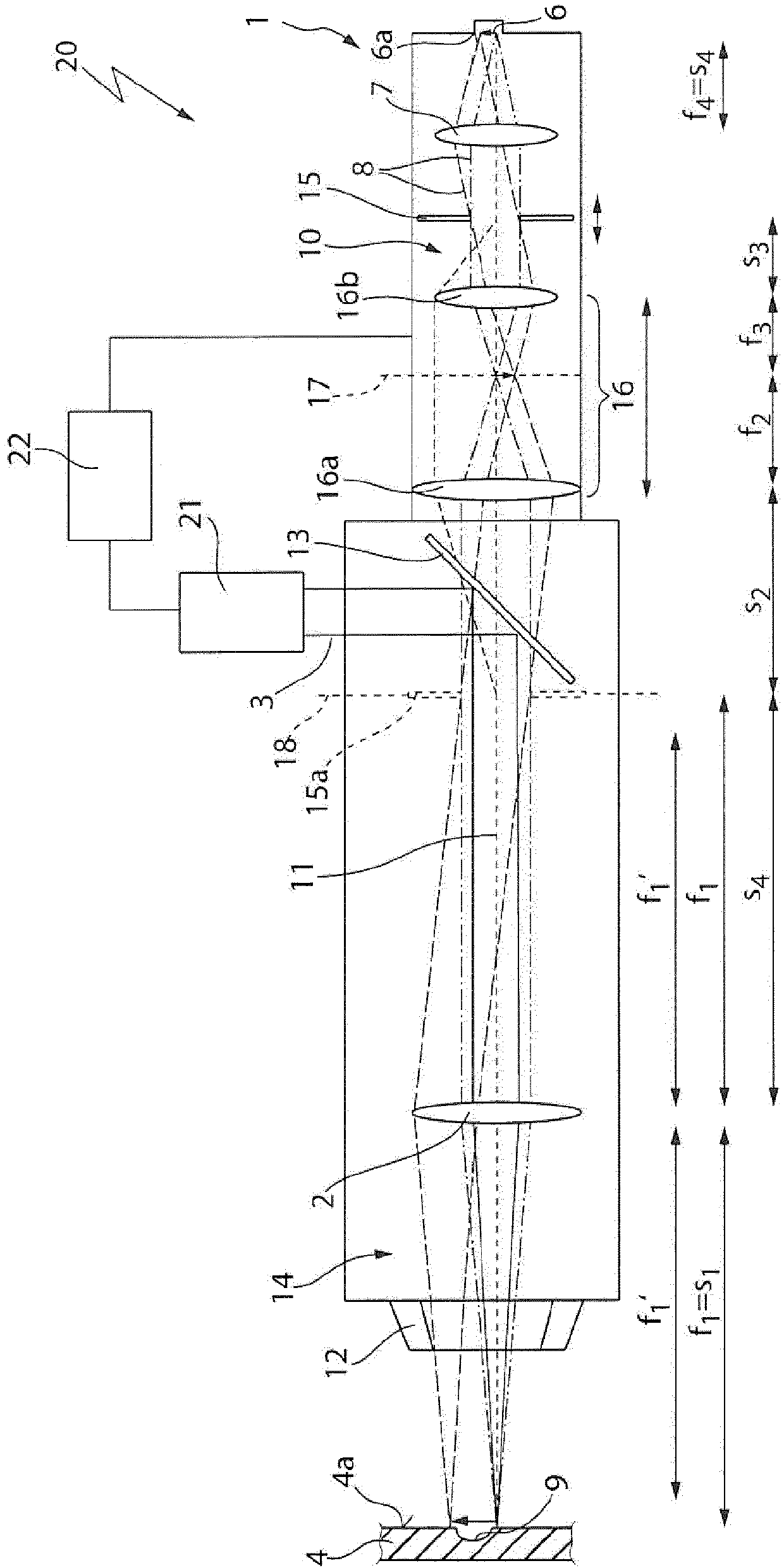

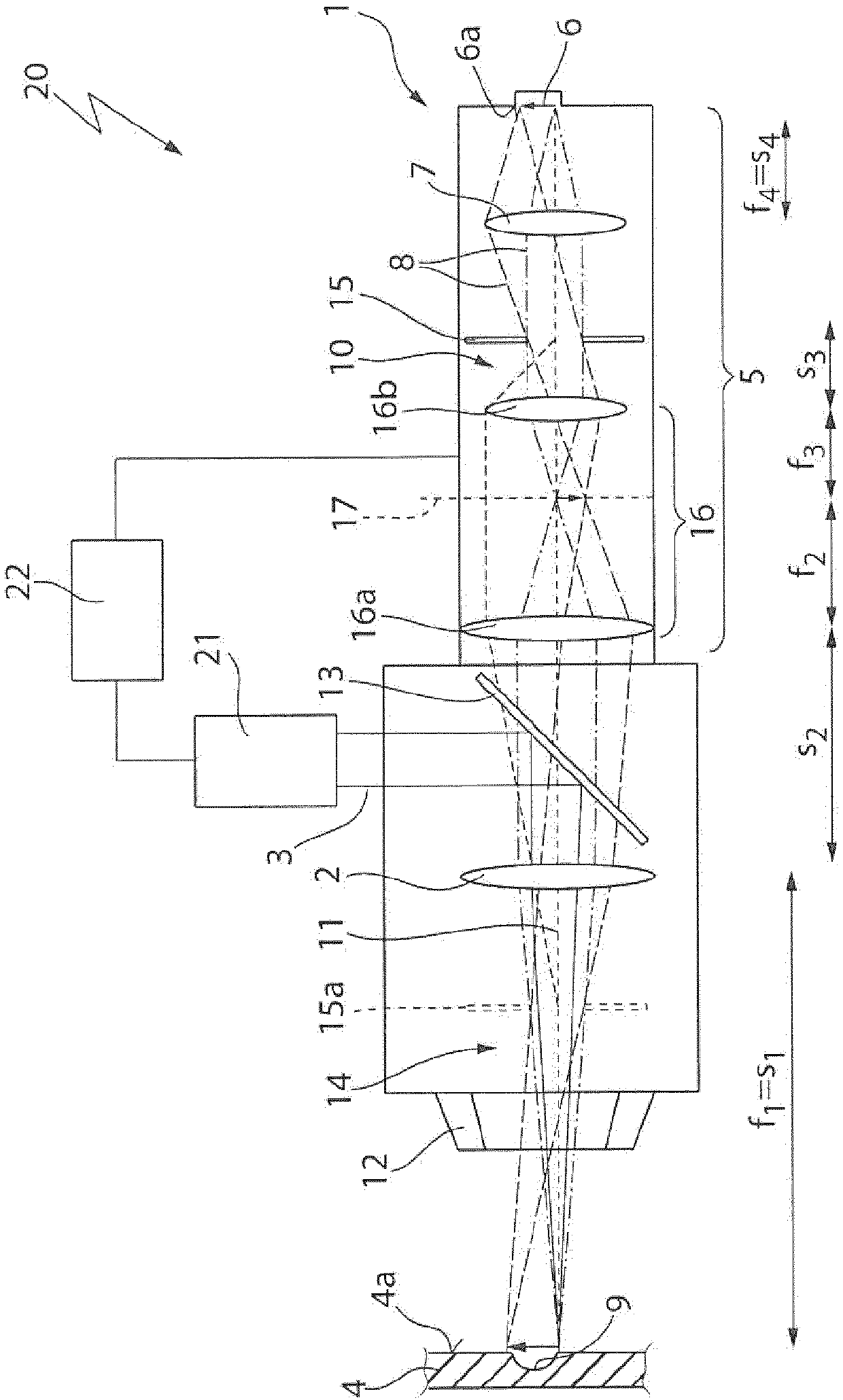

[0036] figure 1 The structure of a laser machining head 1 is shown by way of example, which has a focusing device in the form of a focusing lens 2 for focusing a machining laser beam 3 onto a workpiece 4 . In the example shown, the workpiece 4 , more precisely the workpiece surface 4 a is arranged at a distance with respect to the focusing lens 2 which corresponds to the focal length f of the focusing lens 2 . 1 or object distance s 1 . Furthermore, the laser processing head 1 has an optical imaging device 5 with a detector 6 . The optics 7 in the form of lenses are arranged with the detector 6 in the following distance - this distance is the focal length f of the optics 4 or object distance s 4 , and this optics together with the focusing lens 2 is used to image the workpiece surface 4a, which constitutes the object plane of the optical imaging device 5, onto the following image plane: The detector 6, more precisely the radiation-sensitive surface 6a of the detector 6, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com