Method for guiding a machining head along a track to be machined

A technology for processing and processing heads, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., and can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

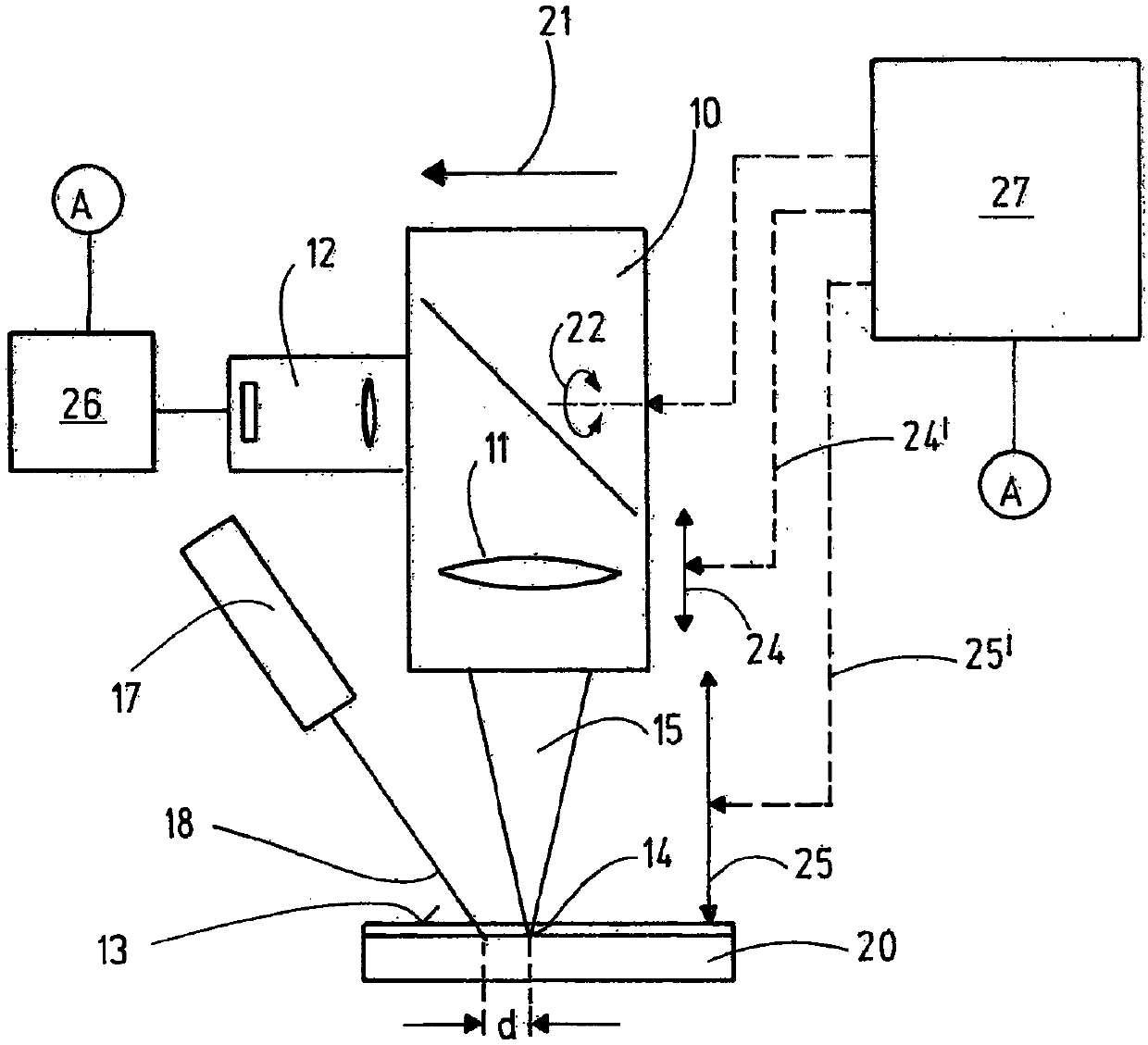

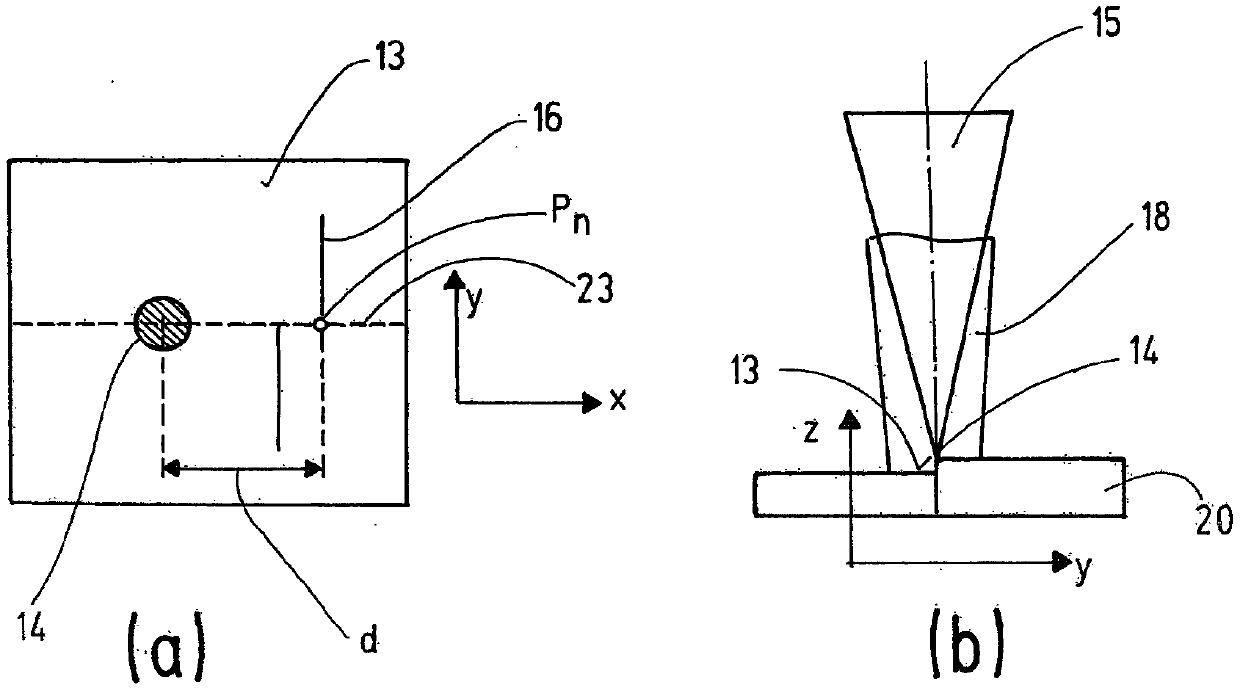

[0021] figure 1 A machining head, in particular a laser machining head 10, is shown in a very simplified manner with a beam-shaping optics 11 and a camera 12 and light 16 for viewing the workpiece surface 13 in the region of the point of incidence 14 of the machining laser beam 15 , which is also referred to below simply as laser beam 15 , which is projected by a light-section projector 17 by means of a light fan 18 onto the surface 19 of the workpiece 20 .

[0022] The laser processing head 10 is guided in the feed direction 21 by a machine control device (not shown in detail) at a speed corresponding to the processing process. As indicated by the double arrow 22, the laser processing head 10 can be pivoted or also moved laterally in order to keep the point of incidence 14 of the laser beam 15 precisely on the trajectory 23 to be processed, ie between the two workpiece parts on the butt seam. The machine controls are also used to adjust the beam shaping optics 11 , in parti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap