Process for selective oligomerization of Ethylene

A technology for ethylene oligomerization and ethylene oligomer, which is applied in the field of ethylene oligomerization reaction technology, can solve the problems of temperature drop and rise of reaction mixture, and achieve the effects of minimizing ethylene polymer by-products, high industrialization, and realizing industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

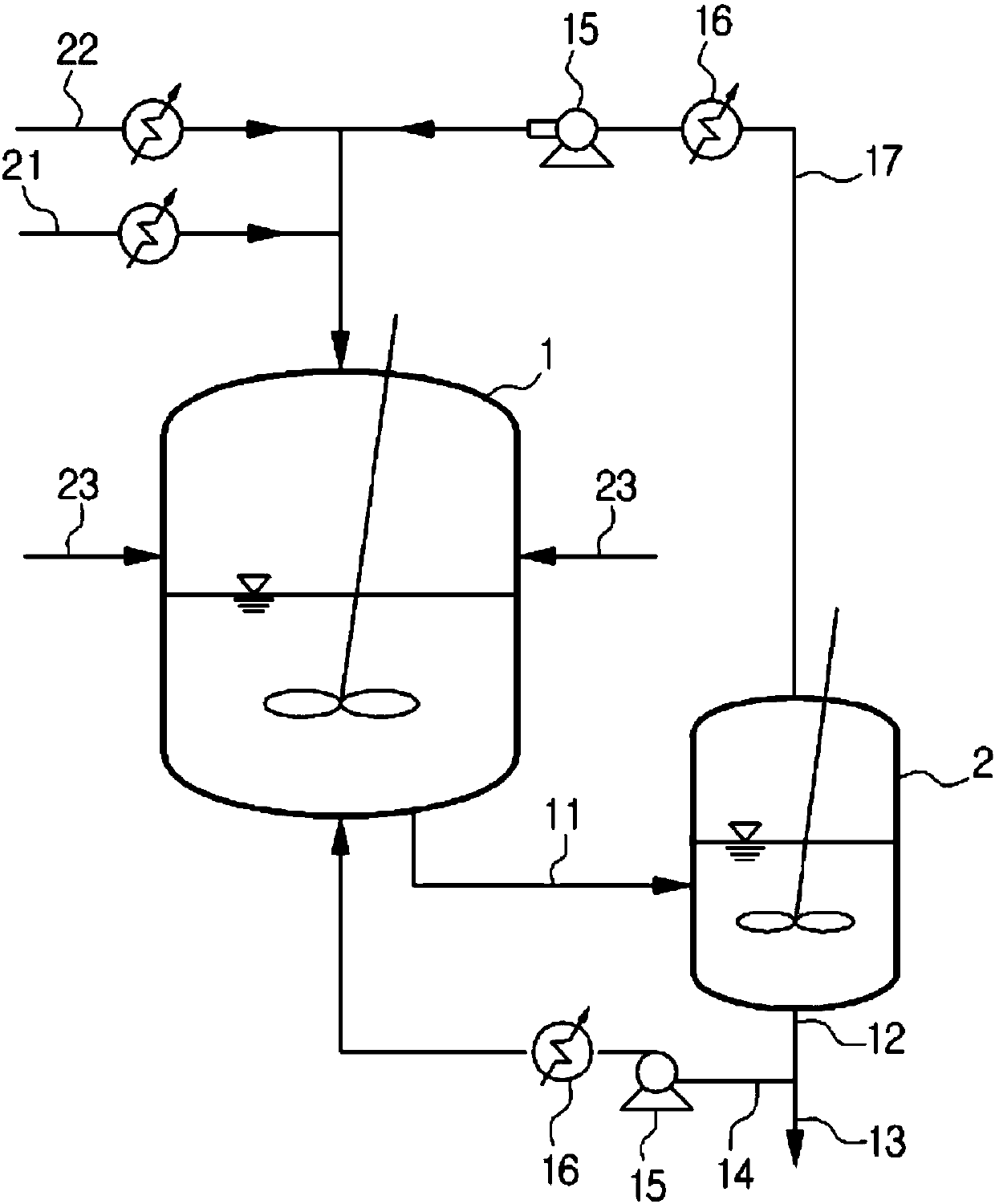

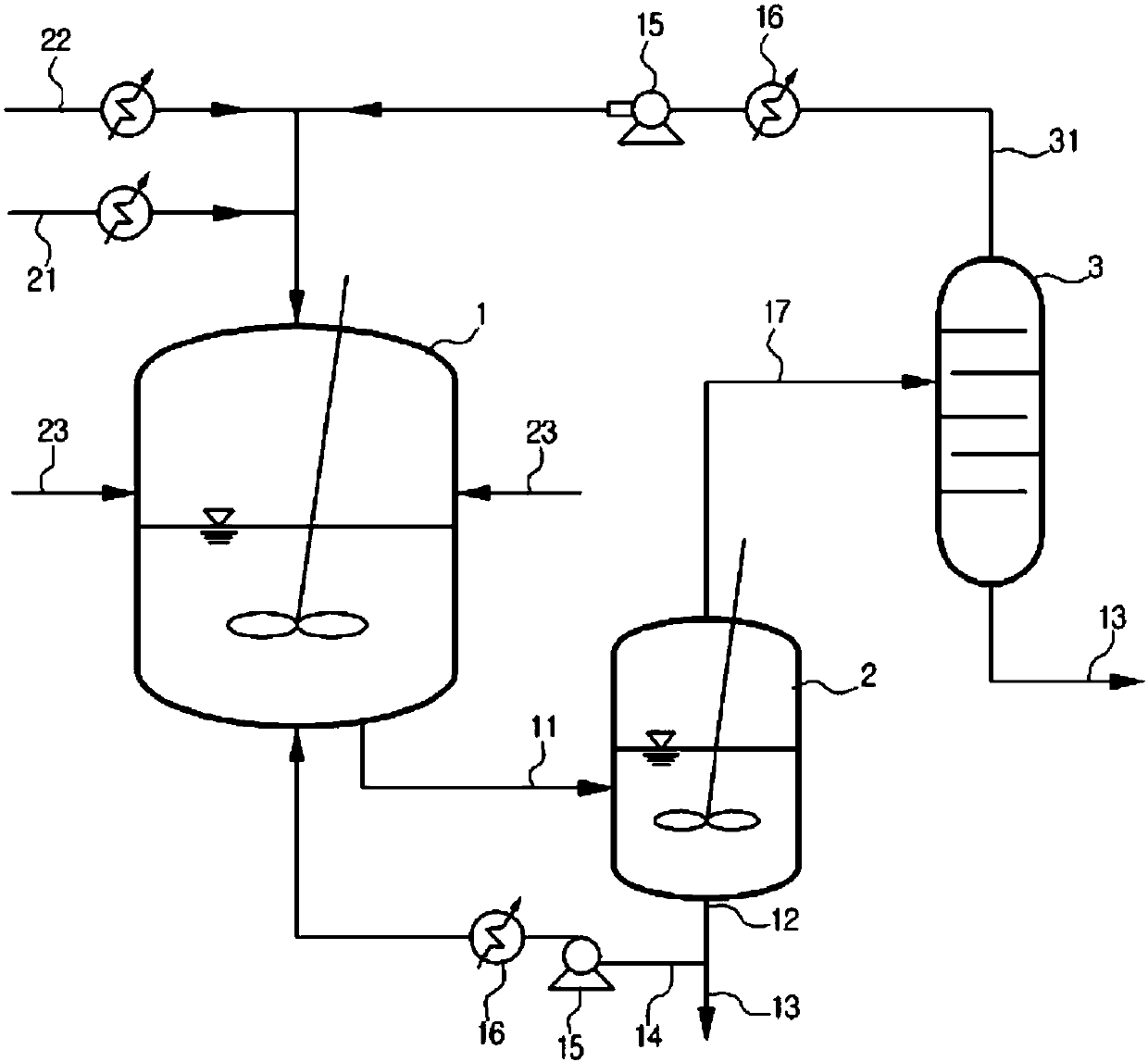

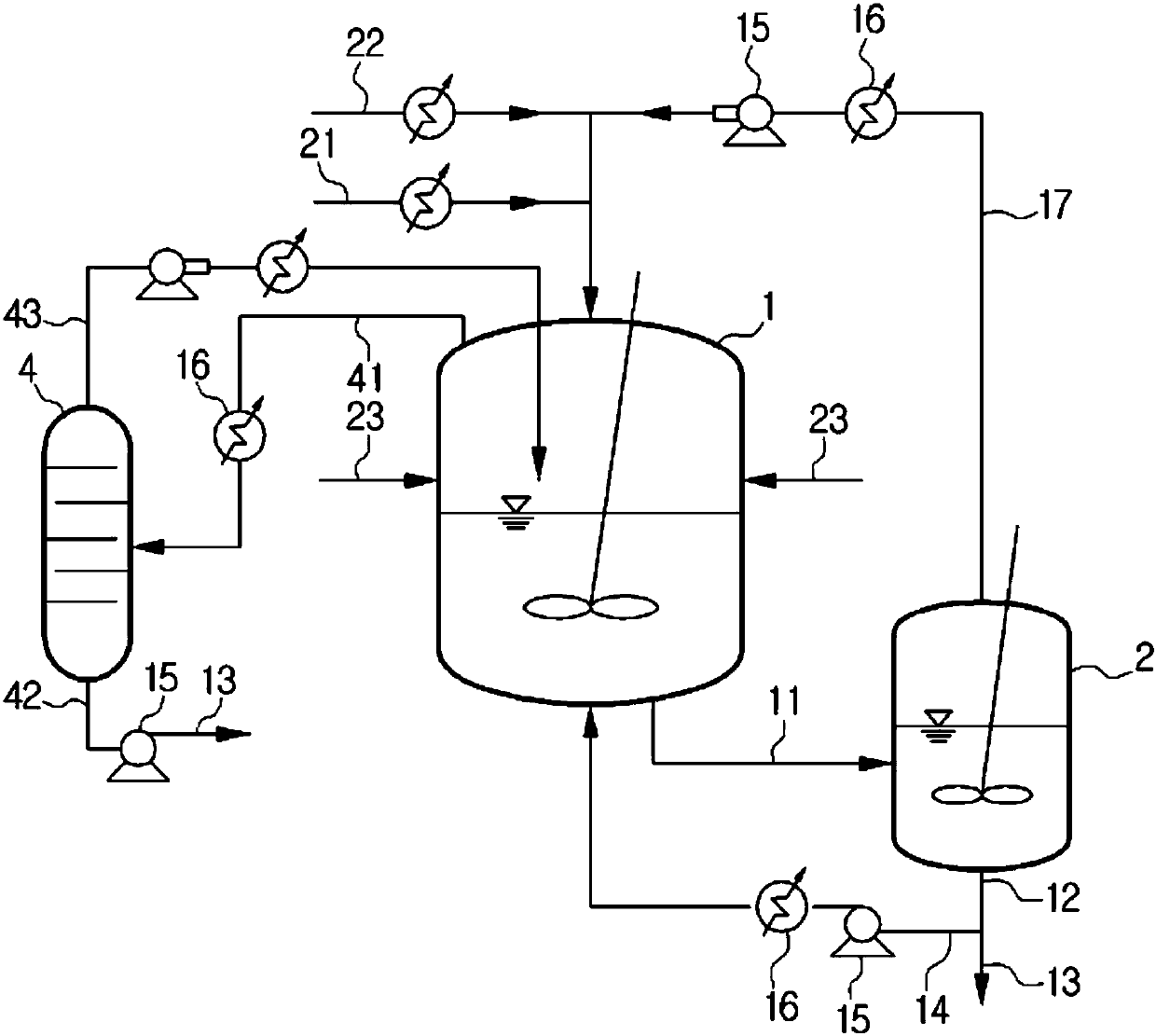

[0053] Hereinafter, the method for producing an oligomer from ethylene according to the present invention will be specifically described. In order to fully convey the idea of the present invention to those skilled in the art, the following embodiments and accompanying drawings are provided. And, unless otherwise defined, the used technical terms and scientific terms have the meanings commonly understood by those having ordinary knowledge in the technical field to which the present invention belongs. In the following description, descriptions of well-known techniques and configurations that obscure the gist of the present invention are omitted.

[0054] Throughout the specification, the term "polyethylene by-product" means, among the products produced in the present invention, "a high molecular weight polyethylene polymer by-product that exists in a solid form at room temperature at 20°C to 30°C"; the term "low The "polymer product" means "by-products of ethylene oligomers t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com