Hay cutting equipment for animal husbandry

A cutting equipment, animal husbandry technology, applied in cutting equipment, agriculture, application and other directions, can solve the problems of manual picking, inconvenient collection, time-consuming and laborious cutting, etc., to achieve the effect of stable cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

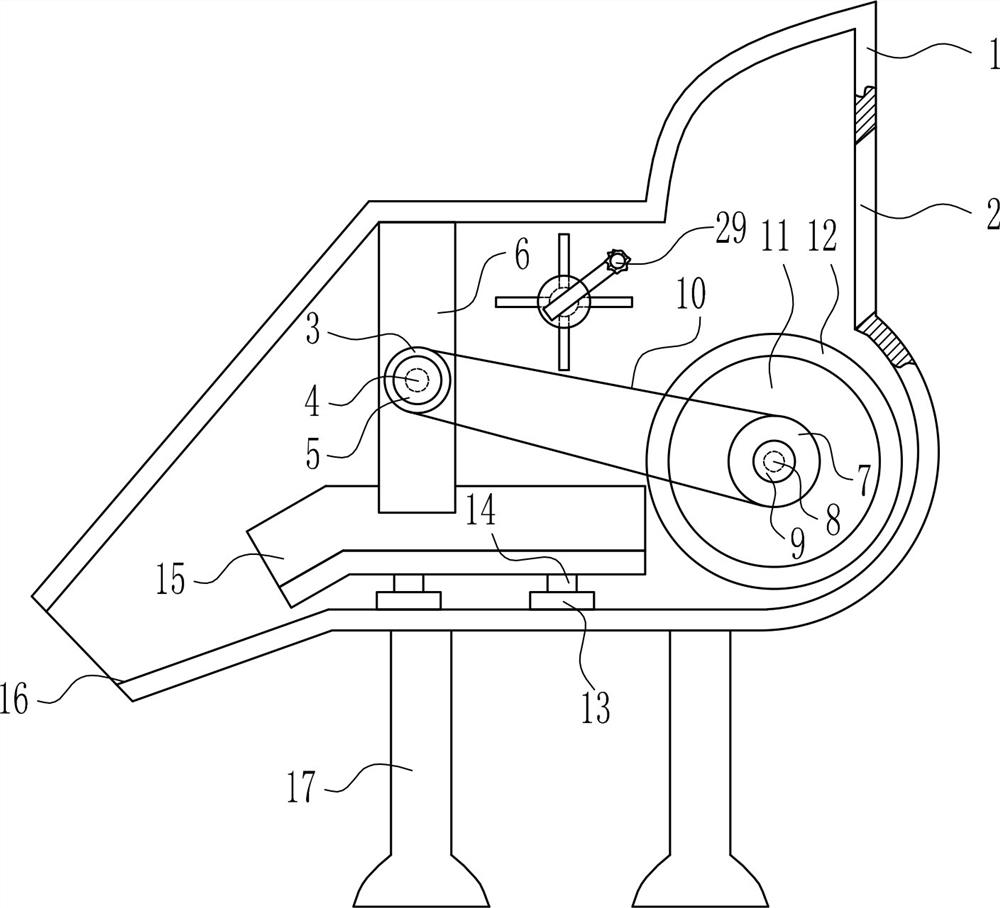

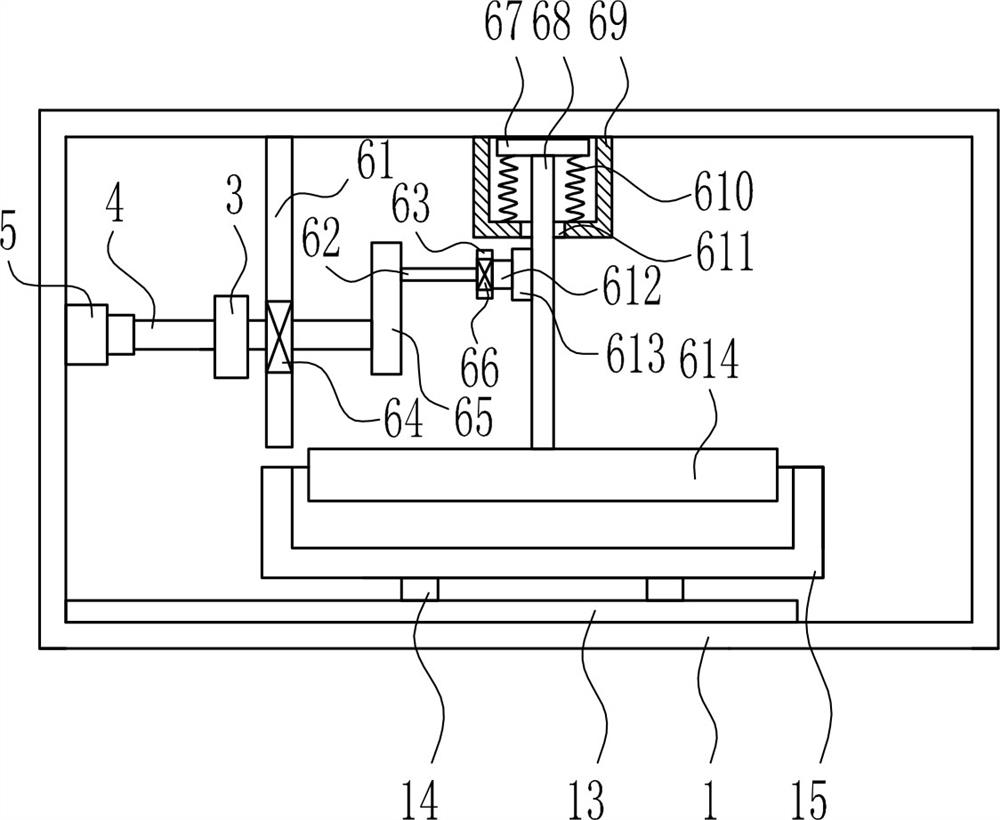

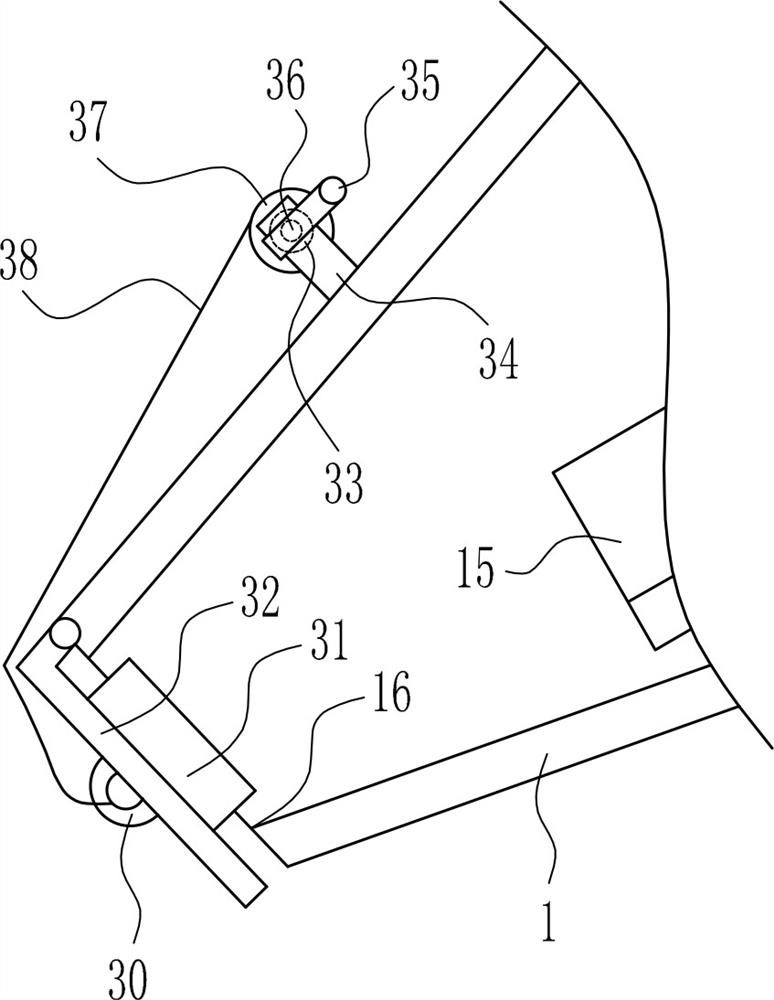

[0032] A kind of forage cutting equipment for animal husbandry, such as Figure 1-7 As shown, it includes a box body 1, a driving wheel 3, a first rotating shaft 4, a motor 5, a mowing device 6, a driven wheel 7, a third rotating shaft 8, a third bearing seat 9, a flat belt 10, a cylinder 11, a guide Circular ring 12, second slide rail 13, second slide block 14, cutting guide rail 15 and pillar 17, pillars 17 are symmetrically arranged at the bottom of box body 1, outlet 16 is arranged at the left part of box body 1, and the upper right wall of box body 1 is arranged There is an entrance 2, a third bearing seat 9 is arranged on the front wall and the lower right part of the rear wall of the box body 1, a third rotating shaft 8 is arranged on the third bearing seat 9, a cylinder 11 is arranged on the third rotating shaft 8, and a cylinder 11 A guide ring 12 is arranged symmetrically on the upper and lower sides, a driven wheel 7 is arranged on the third rotating shaft 8, and th...

Embodiment 2

[0034] A kind of forage cutting equipment for animal husbandry, such as Figure 1-7 As shown, it includes a box body 1, a driving wheel 3, a first rotating shaft 4, a motor 5, a mowing device 6, a driven wheel 7, a third rotating shaft 8, a third bearing seat 9, a flat belt 10, a cylinder 11, a guide Circular ring 12, second slide rail 13, second slide block 14, cutting guide rail 15 and pillar 17, pillars 17 are symmetrically arranged at the bottom of box body 1, outlet 16 is arranged at the left part of box body 1, and the upper right wall of box body 1 is arranged There is an entrance 2, a third bearing seat 9 is arranged on the front wall and the lower right part of the rear wall of the box body 1, a third rotating shaft 8 is arranged on the third bearing seat 9, a cylinder 11 is arranged on the third rotating shaft 8, and a cylinder 11 A guide ring 12 is arranged symmetrically on the upper and lower sides, a driven wheel 7 is arranged on the third rotating shaft 8, and th...

Embodiment 3

[0037] A kind of forage cutting equipment for animal husbandry, such as Figure 1-7 As shown, it includes a box body 1, a driving wheel 3, a first rotating shaft 4, a motor 5, a mowing device 6, a driven wheel 7, a third rotating shaft 8, a third bearing seat 9, a flat belt 10, a cylinder 11, a guide Circular ring 12, second slide rail 13, second slide block 14, cutting guide rail 15 and pillar 17, pillars 17 are symmetrically arranged at the bottom of box body 1, outlet 16 is arranged at the left part of box body 1, and the upper right wall of box body 1 is arranged There is an entrance 2, a third bearing seat 9 is arranged on the front wall and the lower right part of the rear wall of the box body 1, a third rotating shaft 8 is arranged on the third bearing seat 9, a cylinder 11 is arranged on the third rotating shaft 8, and a cylinder 11 A guide ring 12 is arranged symmetrically on the upper and lower sides, a driven wheel 7 is arranged on the third rotating shaft 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com