Automatic cleaning system for display screen

A technology for automatic cleaning and display, applied in the direction of cleaning flexible objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as damage to LCD screens, achieve labor-saving, manpower-saving, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

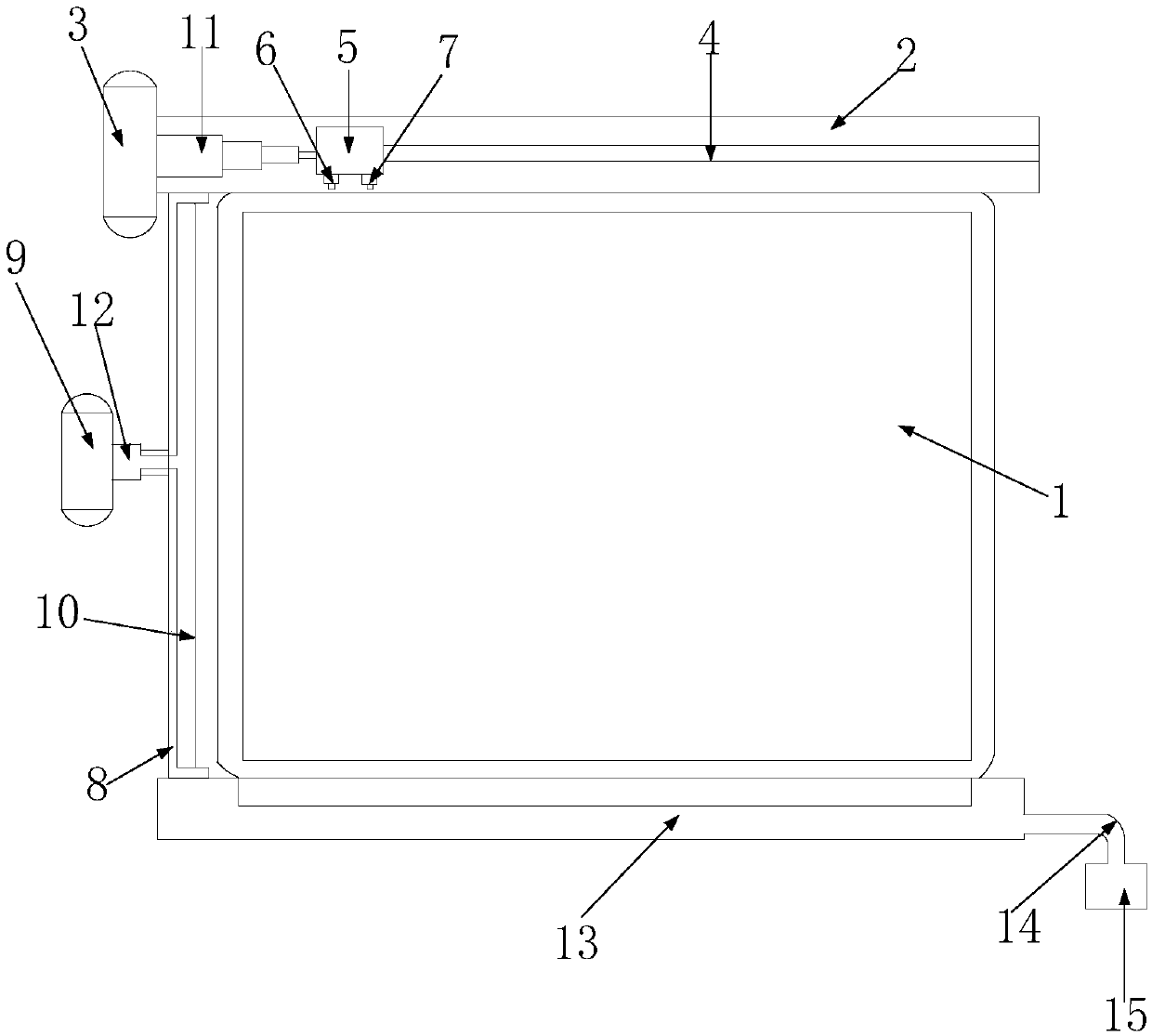

[0020] Such as figure 1 As shown, the display screen automatic cleaning system includes a liquid crystal screen 1, a first support rod 2 is arranged horizontally on the top of the liquid crystal screen 1, a first drive motor 3 is arranged on the left side of the first support rod 2, and a first support rod 3 is arranged on the left side of the first support rod. 2. A chute 4 is set in the middle, and a slide plate 5 is set on the chute 4. A water spray head 6 and a liquid spray head 7 are set on the slide plate 5. The slide plate 5 and the first drive motor 3 pass through the first telescopic The rod 11 is connected, the left side of the screen is vertically provided with a second support rod 8, the left side of the second support rod 8 is provided with a second drive motor 9, the surface of the second support rod 8 is provided with a cleaning cloth 10, and the cleaning The cloth 10 is a dust-free wiping cloth or a superfine fiber dust-free cloth. The second support rod 8 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com