A Design Method of Gravure Printing Machine Oven with Consistent Air Nozzle Air Velocity

A design method and technology of gravure printing machine, applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc. The method is simple and clear, the printing speed is improved, and the effect of overprinting inaccuracy is overcome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for designing an oven for a gravure printing machine with consistent air nozzle wind speed, which is specifically implemented according to the following steps:

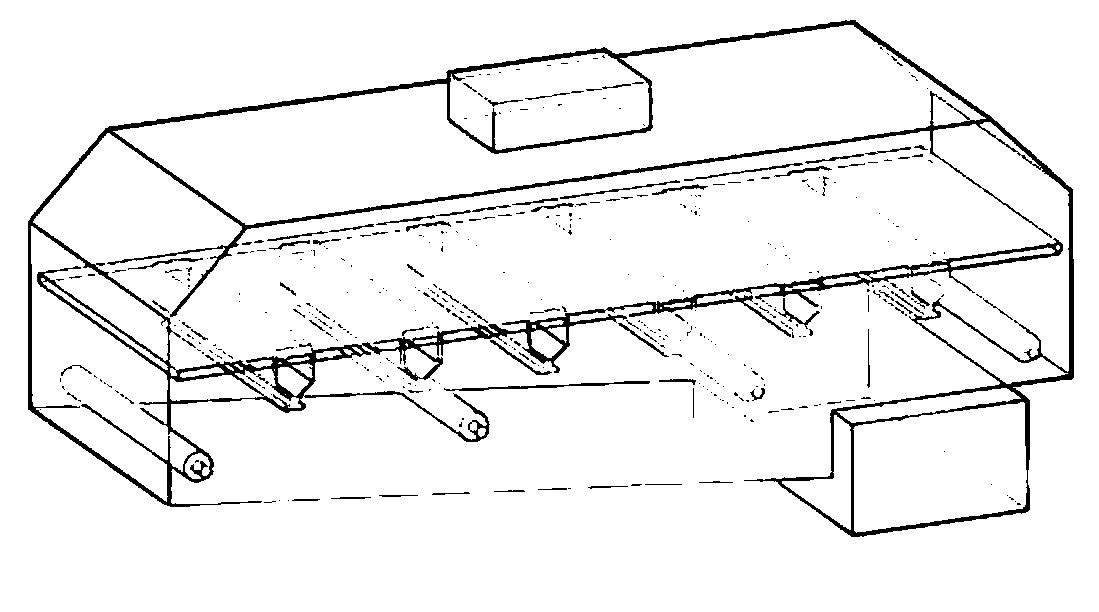

[0045] Step 1: Design the oven structure of the gravure printing machine according to the operating speed of the gravure printing machine, unit space, printing process, and drying requirements, such as figure 1 As shown, the structure design of the gravure printing machine oven includes the structure and arrangement of the fixed box, the movable box, the air inlet, the air outlet, the air nozzle and the guide roller, and the overall size of the oven is determined to be 2020mm*720mm*860mm, and the opening of the air nozzle is uniformly set as 3mm.

[0046] Step 2: Use the 3D design software to model the fluid domain of the designed oven, and then use the grid processing software GAMBIT to discretize the fluid domain, that is, use the method of dividing the grid by area to divide...

Embodiment 2

[0056] This embodiment provides a method for designing an oven for a gravure printing machine with consistent air nozzle wind speed, which is specifically implemented according to the following steps:

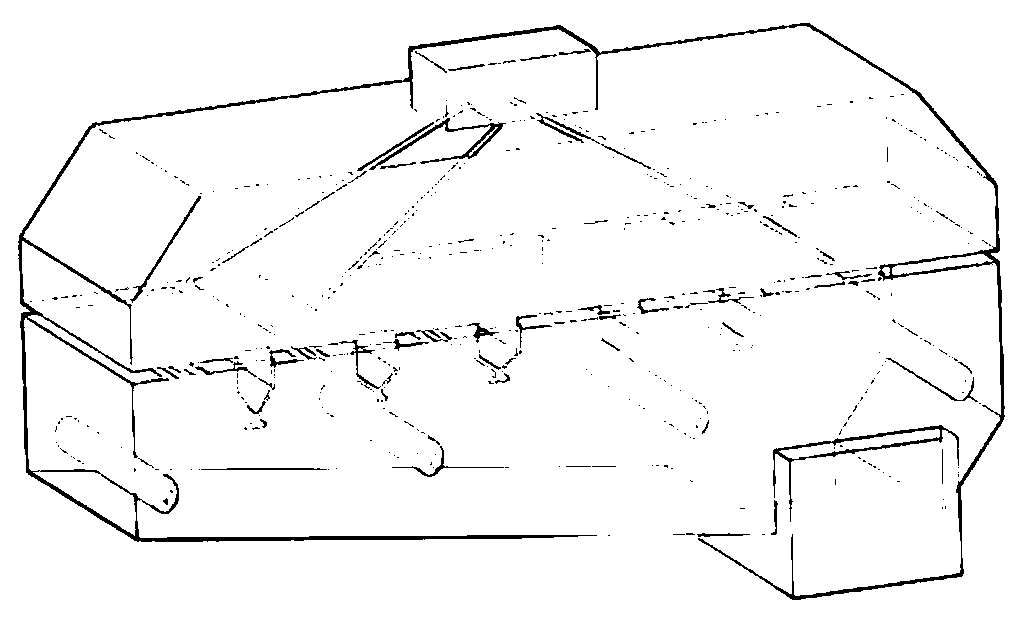

[0057] Step 1: Design the oven structure of the gravure printing machine according to the operating speed of the gravure printing machine, unit space, printing process, and drying requirements, such as image 3 As shown, the structure design of the gravure printing machine oven includes the structure and arrangement of the fixed box, the movable box, the air inlet, the air outlet, the air nozzle and the guide roller, and the overall size of the oven is determined to be 2100mm*800mm*650mm, and the opening of the air nozzle is uniformly set as 4mm.

[0058] Step 2: Use the 3D design software to model the fluid domain of the designed oven, and then use the grid processing software GAMBIT to discretize the fluid domain, that is, use the method of dividing the grid by area to divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com