A Noise Reducing Marine Propeller

A propeller and marine technology, applied in the direction of rotary propellers, rotary propellers, etc., can solve the problems of affecting the ride experience of crew and passengers, loud noise, etc., and achieve the effects of reducing contact, noise, and flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

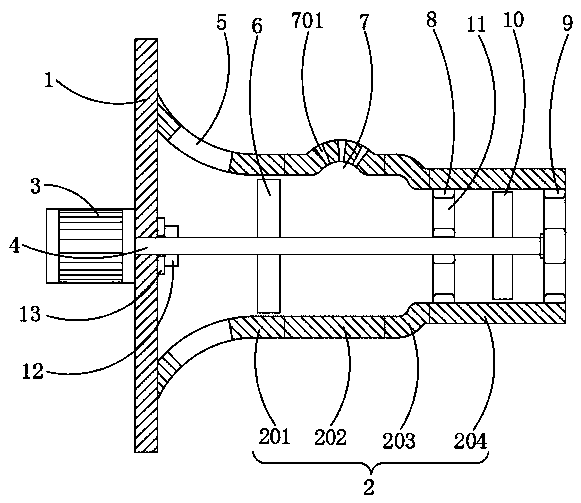

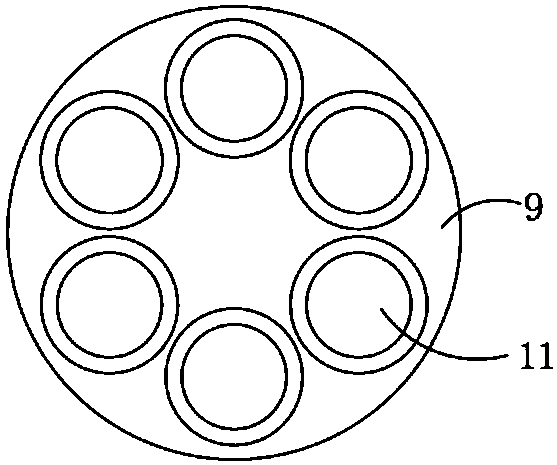

[0018] Such as Figure 1-2 As shown, a noise-reducing marine propeller of the present invention includes a casing 2 fixed on the outside of the hull 1, a driving motor 3 is fixed on the inside of the hull 1, and a rotating shaft 4 is connected to the driving end of the driving motor 3, and the rotating shaft 4 is far away from One end of the driving motor 3 runs through the hull 1 and extends into the casing 2. A locking ring 12 is threaded on the rotating shaft 4. The side of the locking ring 12 close to the hull 1 is provided with a gasket ring 13. There are 13 sets of gasket rings. Set on the rotating shaft 4, by rotating the locking ring 12, the gasket ring 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com