Low glossiness nonreflecting soft-touch effect automobile interior material and preparation method thereof

A low-gloss, automotive interior technology, applied in the field of polymer materials, can solve problems such as lack of soft touch, gloss reduction, and material use restrictions, and achieve the effect of enhancing visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

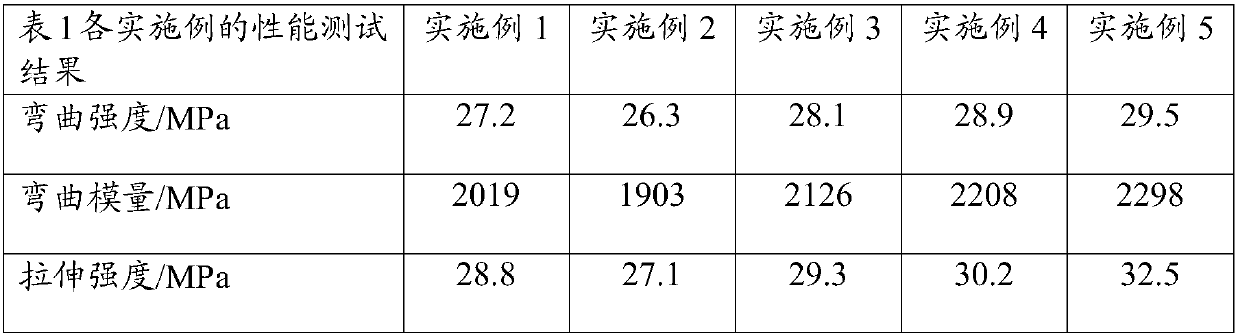

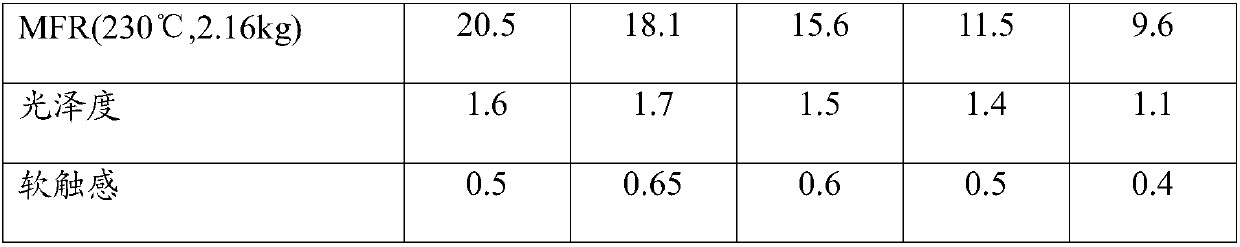

Examples

Embodiment 1

[0021] A preparation method of a low-gloss soft-touch polypropylene composite material, comprising the following steps:

[0022] 40kg of high-strength and high-melt index copolymerized polypropylene material (brand K7100), 30kg of styrene block copolymer (SEBS, brand YH-503, purchased from Sinopec), 5kg of mica powder, and 3kg of maleic anhydride Polypropylene (trademark CMG9801, purchased from Nantong Rizhisheng), 0.25kg of antioxidant 1010 i.e. tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythyl ester (The model is Irganox 1010, BASF of Germany), the antioxidant 168 of 0.25kg is three (2,4-di-tert-butylphenyl) phosphite (the model is Irganox 168, BASF of Germany), the TAF anti-carbon fiber of 1kg is exposed agent, 0.5kg of lubricant (EBS), added to a high-speed mixer and mixed for 5 minutes at a speed of 800 to 1000 rpm to obtain a premix. The premix is added at the main feeding port of the twin-screw extruder, and 20kg of high-strength and high-modul...

Embodiment 2

[0024] A method for preparing a low-gloss soft-touch polypropylene composite material, comprising the following steps:

[0025] 35kg of high-strength and high-melt index copolymerized polypropylene material (brand K7100), 35kg of styrene block copolymer, 5kg of mica powder, 2kg of maleic anhydride grafted polypropylene (brand CMG9801), 0.2kg of anti- Oxygen agent 1010 is tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythyl alcohol ester (model is Irganox 1010, BASF, Germany), 0.2kg of antioxidant 168 is three (2,4-di-tert-butylphenyl) phosphite (model is Irganox 168, BASF, Germany), 0.5kg of TAF anti-carbon fiber exposure agent, 0.3kg of lubricant (EBS). Add it into a high-speed mixer and mix for 8 minutes at a speed of 800-1000 rpm to obtain a premix. The premix is added at the main feeding port of the twin-screw extruder, 20kg of high-strength and high-modulus carbon fiber (brand TC33-3K) is added at the side feeding port, and the temperature of each z...

Embodiment 3

[0027] A method for preparing a low-gloss soft-touch polypropylene composite material, comprising the following steps:

[0028] 30kg of high-strength and high-melt index copolymerized polypropylene material (brand K7100), 35kg of styrene block copolymer, 5kg of mica powder, 5kg of maleic anhydride grafted polypropylene (brand CMG9801), 0.05kg of Oxygen agent 1010 is tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythyl alcohol ester (model is Irganox 1010, BASF, Germany), 0.05kg of antioxidant 168 is three (2,4-di-tert-butylphenyl) phosphite (model is Irganox 168, BASF, Germany), 1.5kg of TAF anti-carbon fiber exposure agent, 0.2kg of lubricant (EBS). Add it into a high-speed mixer and mix for 6 minutes at a speed of 800-1000 rpm to obtain a premix. The premix is added at the main feeding port of the twin-screw extruder, and 25kg of high-strength and high-modulus carbon fiber (brand TC33-3K) is added at the side feeding port. The temperature of each zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com