Construction method of cast-in-place concrete stair closed type formwork

A construction method and concrete technology, which is applied in the preparation of formwork/formwork/work frame, building components on site, construction, etc., can solve problems such as tripping, affecting the regularity of stairs, leaving footprints, etc., to ensure the overall quality, Convenience and quick pouring, easy-to-shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

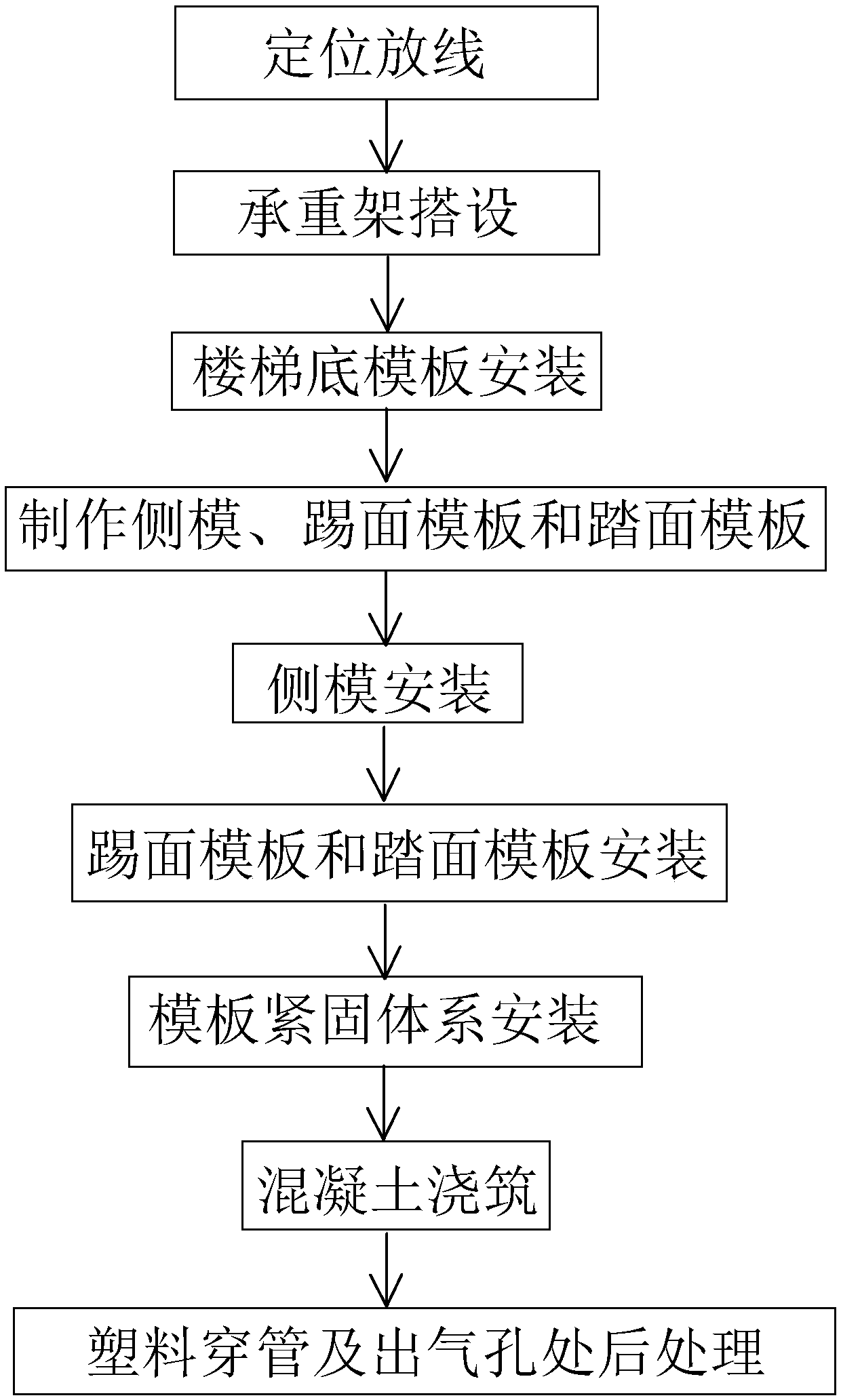

[0023] See figure 1 , the construction method of the cast-in-situ concrete staircase closed formwork of the present embodiment, it is mainly implemented by the following steps:

[0024] ① Positioning and setting out: Use the theodolite to set out the line, and pop up the axis of the stairs.

[0025] ②Load-bearing frame erection: Use seamless steel pipes with a diameter of Φ48mm and a wall thickness of 3.0mm to set vertical poles according to the vertical and horizontal spacing of no more than 90cm, and set up sweeping poles and vertical and horizontal horizontal poles to form a load-bearing frame.

[0026] ③Installation of stair bottom formwork: Determine the oblique length and width of the stairs according to the requirements of the drawing, and after cutting and processing the wooden formwork according to the actual situation on site, install the stair bottom formwork relying on the load-bearing frame.

[0027] ④Make side formwork, riser formwork and tread formwork: Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com