Aluminum alloy fire-resistant window mounting structure

A technology for installing structures and fire-resistant windows, which is applied to windows/doors, fire-resistant doors, building components, etc. It can solve the problems of reduced structural strength, increased overall window weight, and inability to maintain integrity, so as to increase mechanical strength and facilitate disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

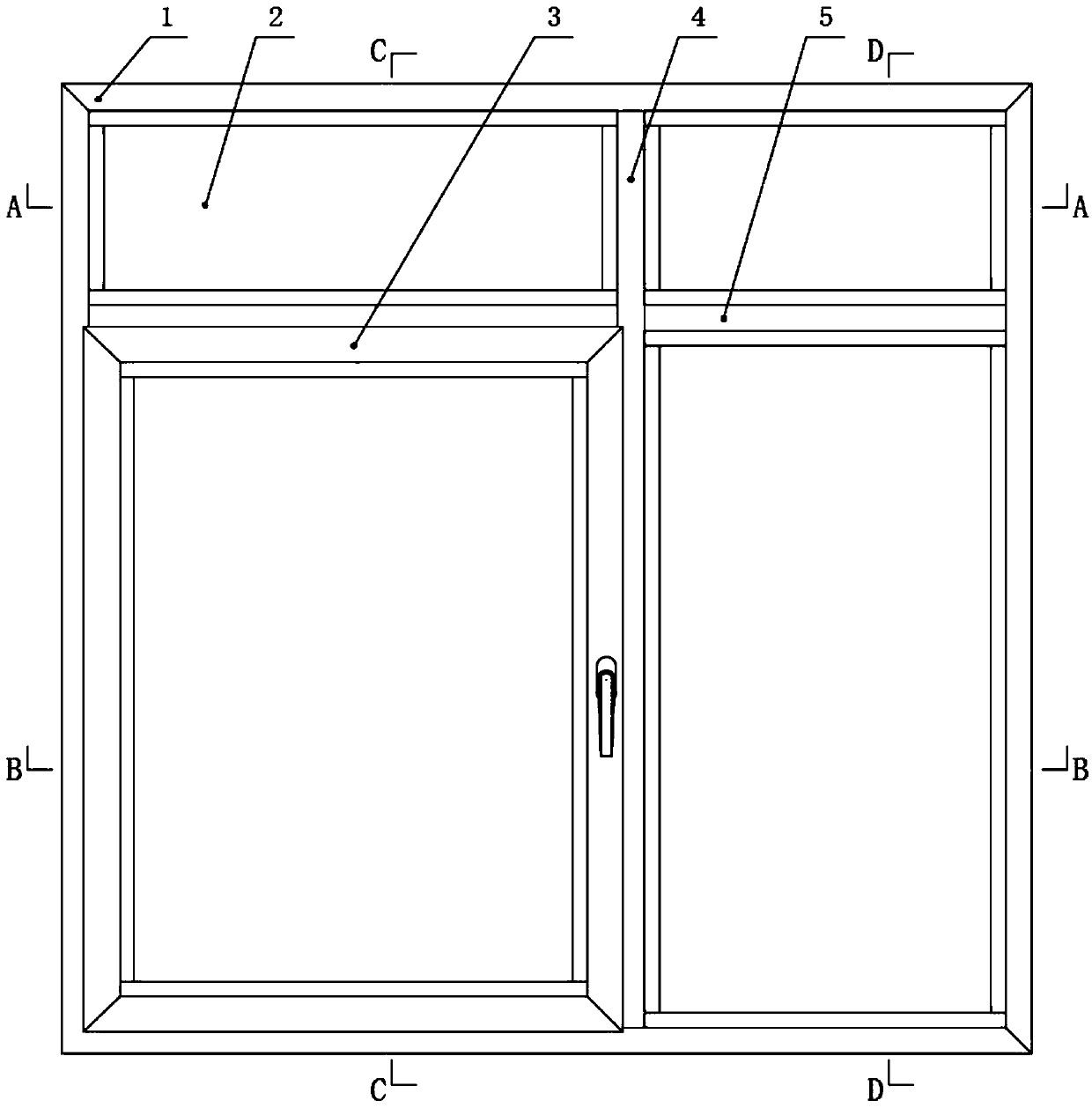

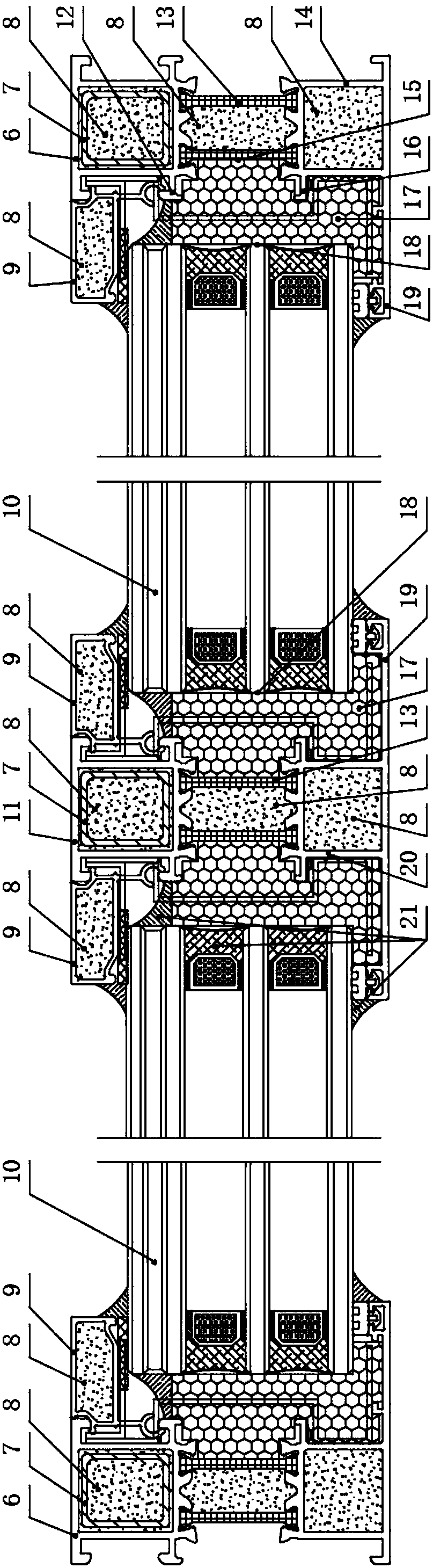

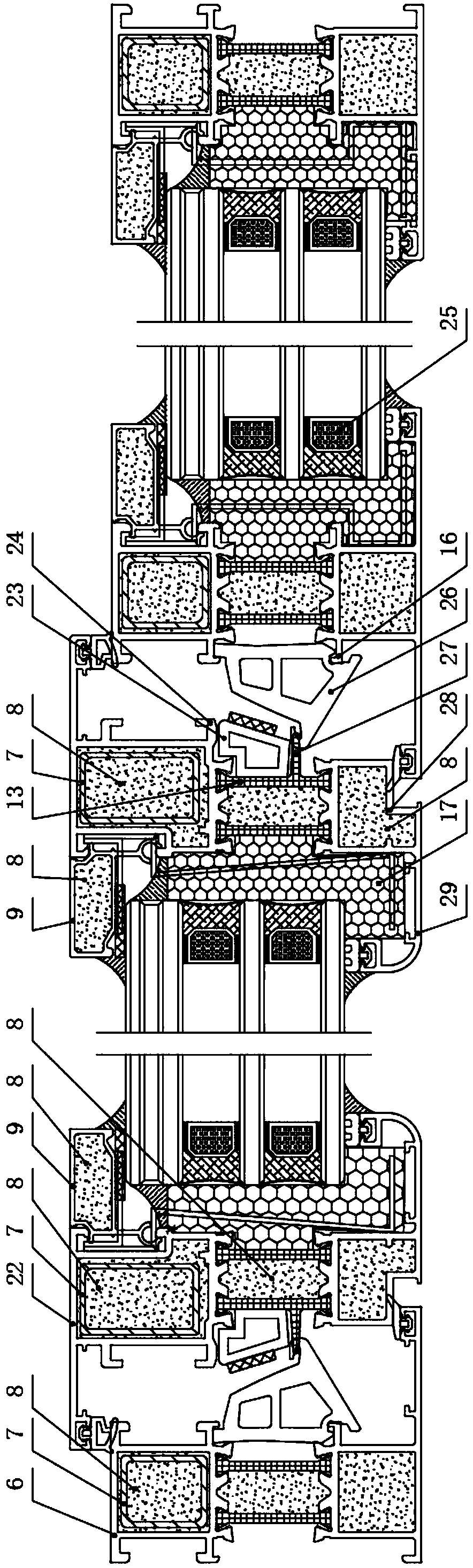

[0044] An aluminum alloy fire-resistant window installation structure, such as Figure 1-22As shown, it includes an outer frame 1, a horizontal middle 5 and a vertical middle 4, and a glass 2 is arranged between the outer frame and the two middle stances. Frame 14 and side inner frame 6, described middle quite comprises the middle very outer frame 20 and middle very inner frame 11 that are installed together by structural member, the inner side of described side inner frame and the both sides of middle very inner frame all are installed with Buckle 9, the outer frame is installed in the window of the building through the mounting parts. The innovation of the present invention is that: the inside of the side inner frame and the middle inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com