Piston buffer pushing device for electrohydraulic actuator

A technology of electro-hydraulic actuators and driving devices, which is applied in the direction of fluid pressure actuating devices, etc., and can solve problems such as affecting the service life of valves, having no cushioning effect, and damage to pistons and matching parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

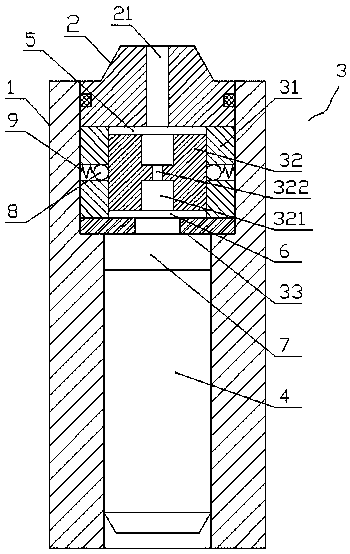

[0018] Example. A piston cushioning and pushing device for an electro-hydraulic actuator, which is composed of figure 1 As shown, the piston cylinder 1 is included, the top of the piston cylinder 1 is provided with a seal seat 2, the bottom of the seal seat 2 is provided with a buffer mechanism 3, and the bottom of the buffer mechanism 3 is provided with a piston rod 4 that can move along the axial direction of the piston cylinder 1; The buffer mechanism 3 includes a shaft sleeve 31, which is fixedly connected with the piston cylinder 1, and a buffer piston 32 is movably connected in the shaft sleeve 31; the sealing seat 2 is provided with a flow channel A21, and the buffer piston 32 is above A flow channel B321 is provided; an oil chamber a5 is provided between the sealing seat 2 and the buffer pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com