Rigid and flexible two-stage locking ball joint

A ball joint and locking ball technology, applied in the field of medical devices, can solve the problems of not being able to operate multiple surgical tools and instruments at the same time, and the operator of clamping surgical tools and instruments cannot operate at the same time, so as to improve the experimental efficiency and Success rate, avoiding overwork, reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

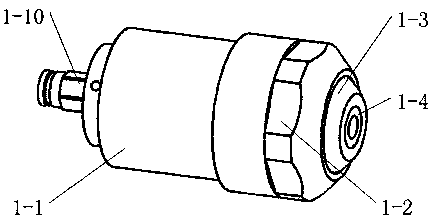

[0028] refer to figure 1 , a rigid-flexible two-stage locking ball joint according to the present invention, its external basic structure is composed of a joint sleeve 1-1, a ball joint cover 1-2, a spherical part 1-3 and a fluid quick connector 1-10. Among them, the ball joint cover 1-2 is connected with the joint sleeve 1-1 through threads, and the outer circumference of the ball joint cover 1-2 has a tightening structure to tighten the two; the fluid quick connector 1-10 is installed on the joint sleeve 1-1 Tail, for the fluid inlet;

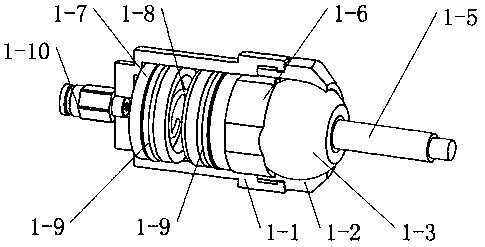

[0029] refer to figure 2 , The ball joint module is composed of a ball joint metal bush 1-4 embedded in the spherical part 1-3, and a connecting rod 1-5 constitutes the ball joint movement part. The main piston 1-6 and the secondary piston 1-7 are covered with a sealing ring 1-9, which can slide in the inner cavity of the joint sleeve 1-1; the main piston 1-6 and the secondary piston 1-7 are installed There is a spring 1-8, and the spring 1...

Embodiment 2

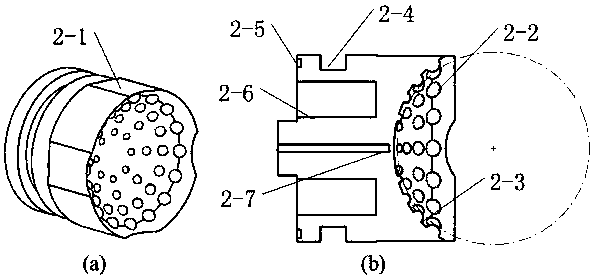

[0035] This embodiment is transformed on the basis of Embodiment 1. In this embodiment, the ball joint module 1 in Embodiment 1 is replaced by a ball joint 4 with a concentric ventilation structure. The concentric ventilation structure can maintain the locking function while The fluid of the ball joint is allowed to flow into the lumen of the adjacent ball joint through the internal flow passage of the local joint. When the concentric ventilation structure ball joint 4 is expanded, one fluid inlet can be used to see that the inner cavities of other ball joints are completely filled.

[0036] see Figure 6 , the concentric air ball joint 4 is composed of a joint sleeve 1-1, a ball joint cover 1-2 and a masonry spherical part 4-3, a ball joint metal bushing 4-4, a hose 4-5, a main piston 4-6, The secondary piston 4-7, the sliding joint 4-8, the sealing ring 4-9, the inner ring sealing ring 1-10 and the fluid quick connector 1-10 are composed. Among them, the ball joint cover 1...

Embodiment 3

[0041] The present embodiment is transformed on the basis of the second embodiment. The exhaust valve 6-3 in the second embodiment can also close the flexible pipe 4-5 at one end of the concentric ventilation ball joint 4 at the end, and other parts are not Change, also realize the locking function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com