Efficient electric furnace system

An electric furnace, high-efficiency technology, applied in the direction of electric furnace heating, furnace, crucible furnace, etc., can solve the problems of low working efficiency and narrow application range of the electric furnace system, and achieve the effect of facilitating later use, high working efficiency and simple control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

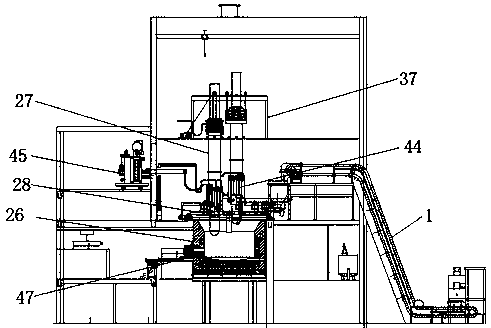

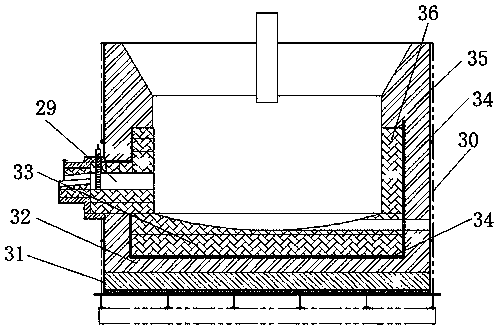

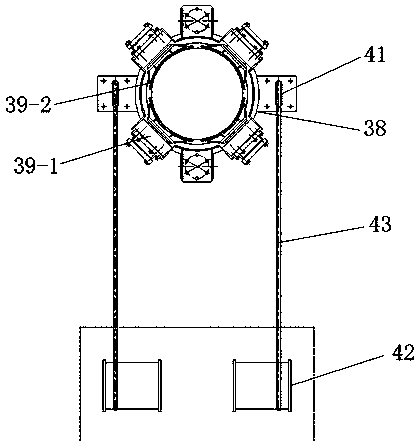

[0025] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] The high-efficiency electric furnace system of this embodiment includes

[0027] Feeding device 1, which feeds raw materials into the electric furnace;

[0028] Additive adding device, add additives to the inside of the electric furnace, and mix with raw materials to form products;

[0029] The additive adding device comprises a raw material tank, a mixing tank and a flow chute, the raw material tank comprises a first resin storage tank 2, a second resin storage tank 3 and an ammonia water tank 4, the output ends of the first resin storage tank and the second resin storage tank After the resin metering pump 5 flows into the mixing tank 6, the output end of the ammonia water tank 4 and the external water source flow into the mixing tank 6 through the pipelines 7 and 8 respectively, and after the stirring and mixing are coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com