Stacking ring shearing box and stacking ring shearing test based on stacking ring shearing box

A technology of shear box and wall ring, which is applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., and can solve the problem of small shear distance in direct shear test, affecting experimental results, and fault tolerance of fixed shear surface Low rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0074] Example 1: Traditional Ring Shear Test

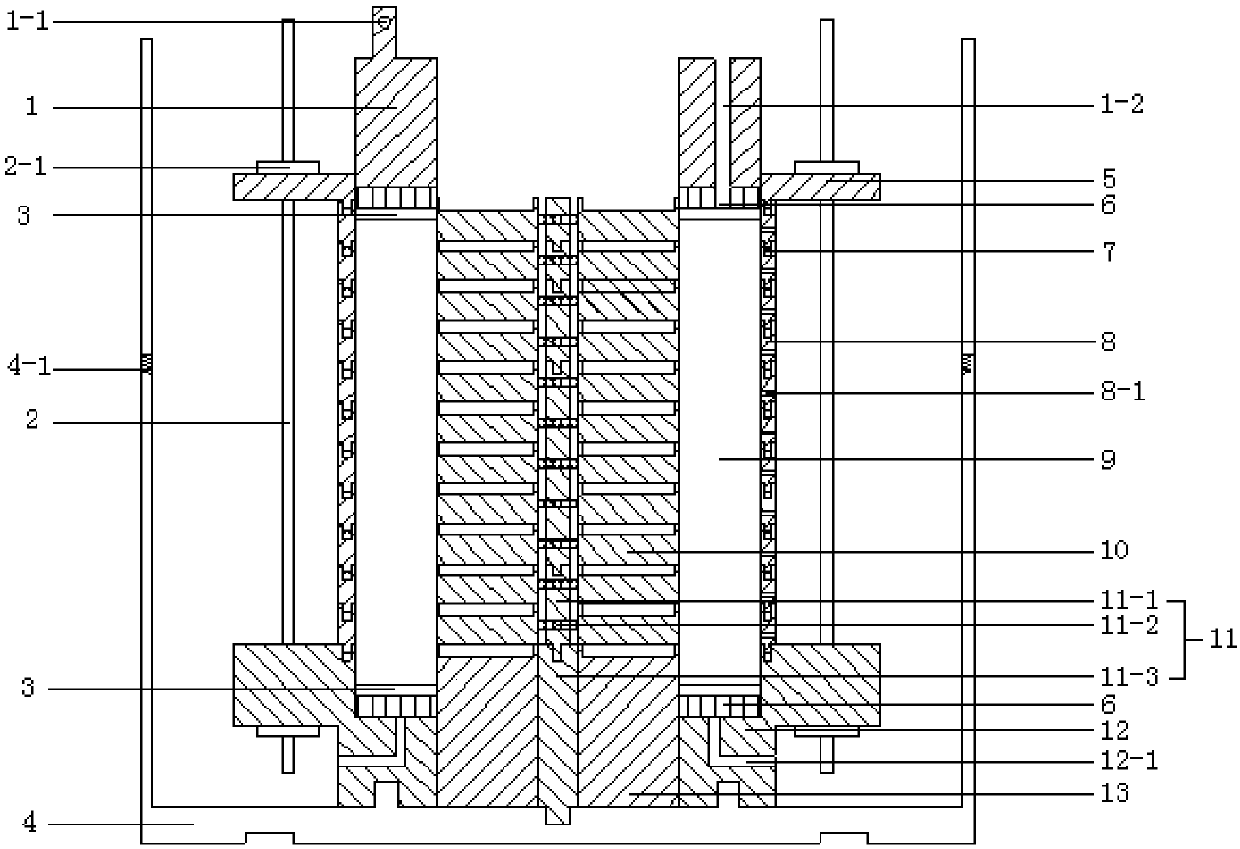

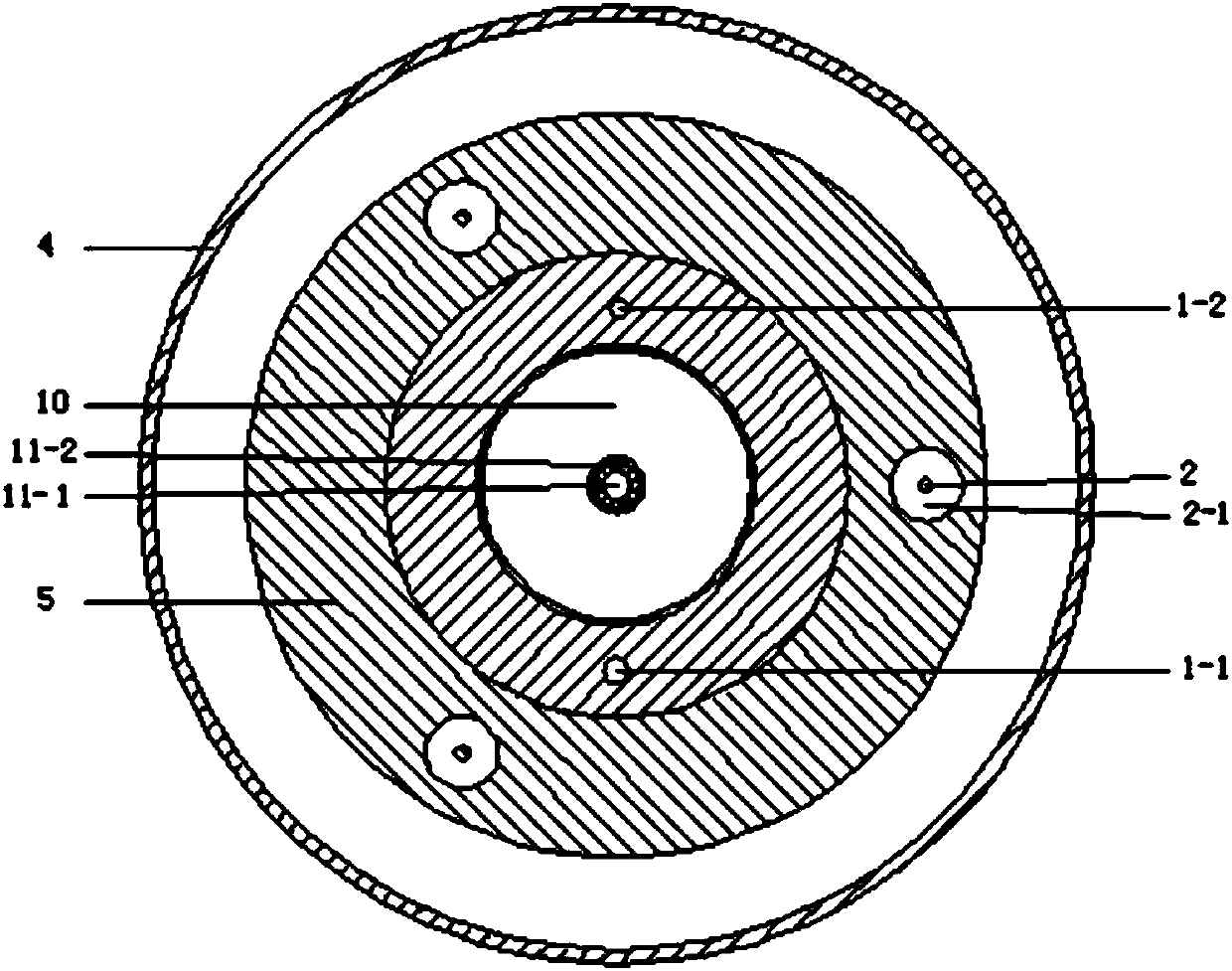

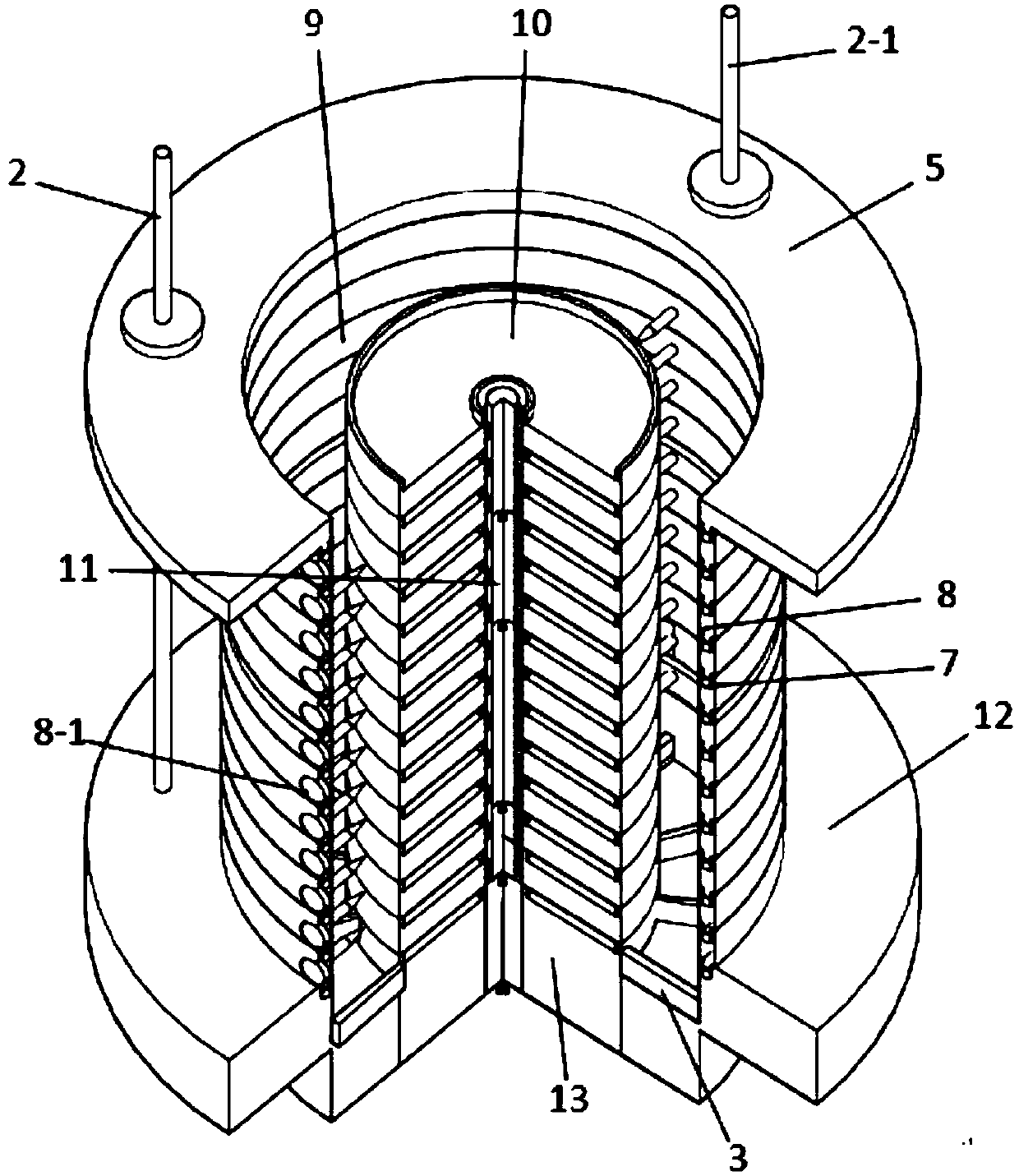

[0075] To carry out the traditional ring shear test, it is only necessary to remove the redundant shear box unit and only keep one shear box unit. During the test, the vertical stress is transmitted and consolidated through the cutter head 1, and the torque is transmitted through the lower shear box 12 during the test, so that The sample is sheared circumferentially along the preset shear plane.

example 2

[0076] Example 2: Stacked Ring Shear Test of Remodeled Soil

[0077] The remolding soil sample preparation process adopts the layered sample preparation mode. First, place the bottom column 13 in the round hole of the lower shear box 12, and insert the fixed shaft 11-3 to fix it. Place the second ball in the annular groove of the lower shear box 12, add a certain amount of lubricating oil, and put a movable wall ring 8 to form the bottom sample groove. Put the soil sample into the sample groove, compact it layer by layer to the height of the wall ring, then place balls in the groove of the upper wall ring and put a layer of wall ring and stack ring. Repeat the above until the required height for the test is reached. Put on the collar 5, insert the shear box support 2 and lock it with the nut 2-1 to complete the sample preparation. After the sample preparation is completed, the completed assembly is moved to the water bath box 4, and the vertical pressure is applied to the sa...

example 3

[0078] Example 3: Undisturbed soil stacked ring shear test

[0079] The sample preparation of the undisturbed soil-stacked ring shear test needs the help of a sample preparation device, which is a cylindrical thin-walled ring cutter, which is characterized in that the assembled movable ring group can be embedded in the cylinder in advance. Insert the sampler together with the movable ring group into the undisturbed soil to take soil samples. Take off the sample preparation device, place the movable ring group and the sample on the lower shear box 12, and ensure that the protrusion on the movable ring 8 engages with the groove of the lower shear box 12. The undisturbed soil is pressed into the lower shear box 12 grooves, and the redundant movable wall ring 8 is sloughed off. Then, a hole is opened in the center of the sample through a ring knife with the same diameter as the lamination. The ring knife is inserted from the upper part of the sample and penetrates to the round ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com