Light multifunctional lattice structure and laser additive material manufacturing method thereof

A lattice structure, multi-functional technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficult to realize pre-embedding, heat transfer, internal space sealing, etc., and achieve reduction of processing technology procedures, good Tensile resistance and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

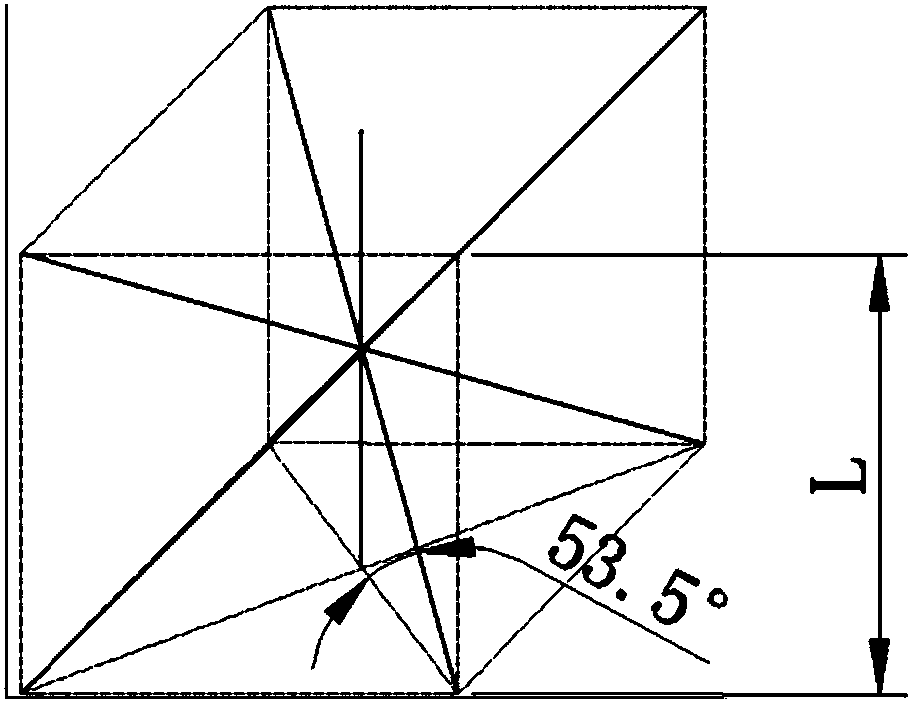

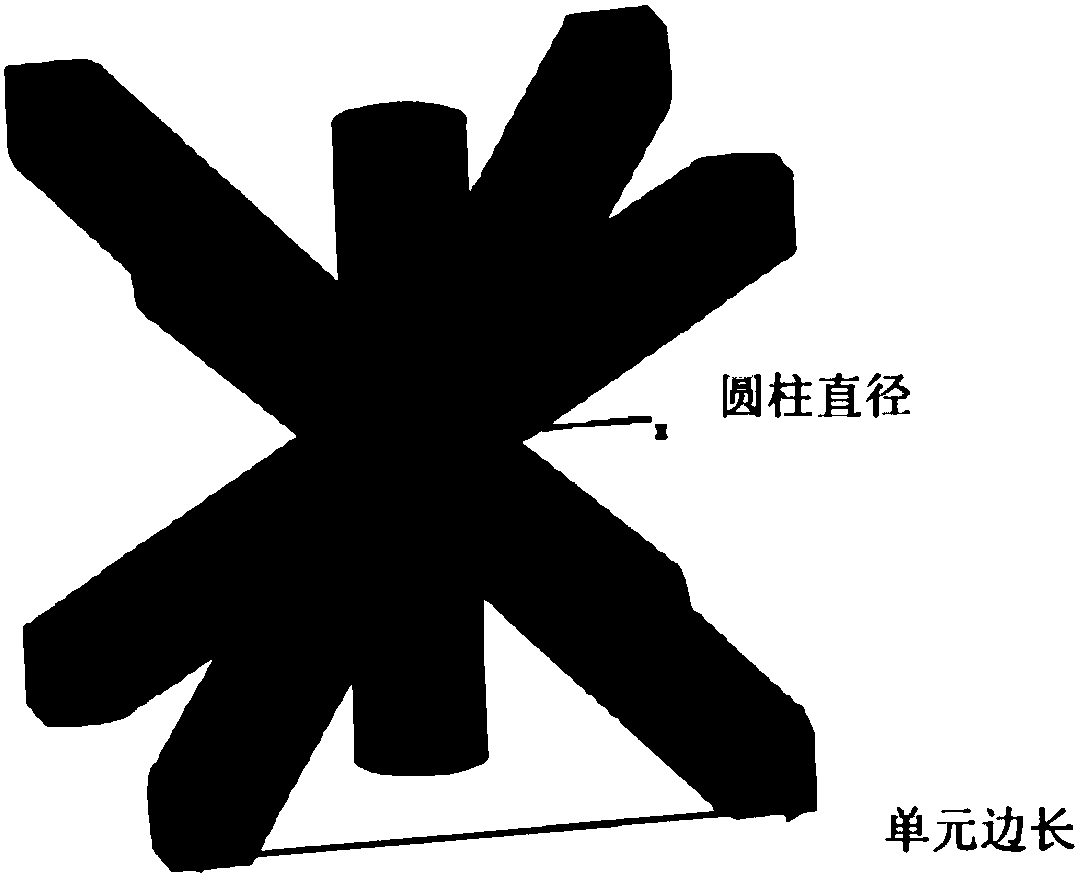

[0032] Such as Figure 1 to Figure 3 Shown, a kind of lightweight multifunctional lattice structure of the present invention, this lattice structure design is as follows:

[0033] 1) Lattice structure unit

[0034] a) Determine the filling side length L and the filling diameter a;

[0035] b) completing the lattice central pillar whose side length is L and whose diameter is a;

[0036] c) According to the angle of 53.5° with the bottom surface, four inclined pillars are designed in the lattice, the length of the inclined pillar is 1.732L, the diameter is a, and the spatial position is the body diagonal of a tetrahedron whose side length is L;

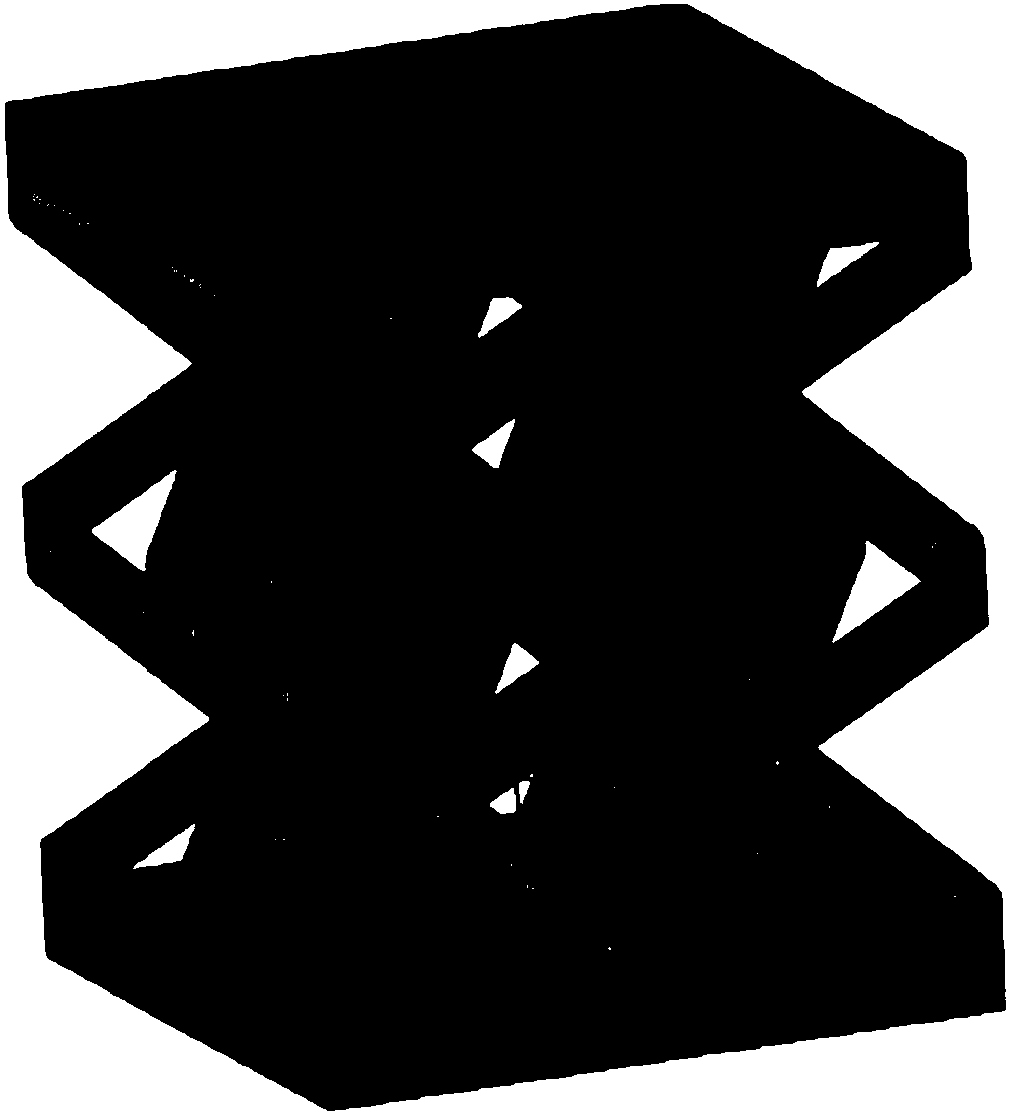

[0037] 2) Lattice structure unit filling

[0038] a) Determine the position to be filled in the component model as required;

[0039] b) Filling the lattice structural units described in step 1) in a three-dimensional software to form a component model.

[0040] The above-mentioned lattice structure unit, the side length of the uni...

Embodiment 2

[0042] A kind of lightweight multifunctional lattice structure and its laser additive manufacturing method described in the present invention, its described lattice structure design is as follows:

[0043] 1) Lattice structure unit

[0044] c) Determine the filling side length L and the filling diameter a;

[0045] d) completing the lattice central pillar whose side length is L and whose diameter is a;

[0046] c) According to the angle of 53.5° with the bottom surface, four inclined pillars of the lattice are designed, the length of the inclined pillars is 1.732L, the diameter is a, and the spatial position is the body diagonal of a tetrahedron whose side length is L;

[0047] 2) Lattice structure unit filling

[0048] a) Determine the position to be filled in the component model as required;

[0049] b) Carry out the filling of the lattice structural unit described in step 1) in the 3D software, and then carry out triangular faceting to form a component model and import i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com