A ceramic firing method for ceramic glaze with invisible anti-counterfeiting function

A technology of functional ceramics and ceramics, which is applied in the field of ceramics and can solve problems such as low temperature resistance and short shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

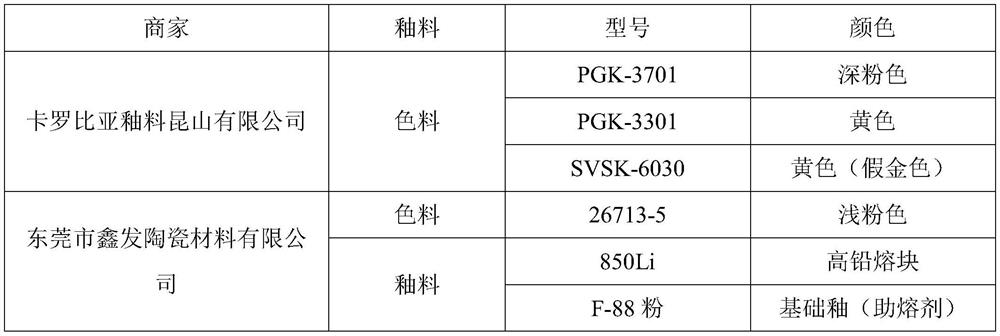

Method used

Image

Examples

Embodiment 1

[0025] 1): Mix glaze powder of any color with anti-counterfeit powder (Youpin Bao Technology (Technology) Beijing Co., Ltd.) in a ratio of 100:0.3 to prepare anti-counterfeit glaze powder;

[0026] 2): In step 1), put the mixed anti-counterfeit glaze powder into a ball mill tank, add 30% water of the total weight, and continue ball milling for more than 24 hours to obtain a water glaze;

[0027] 3): The water glaze obtained in step 2) is filtered with a 200-mesh sieve to obtain a flow rate of 11m / s and a specific gravity of 130g / cm 3 water glaze;

[0028] 4): After the step 3) is completed, immerse the ceramic body in the water glaze to absorb the glaze for 3 seconds, take it out, and wipe the bottom of the body clean;

[0029] 5): The glaze base obtained in step 4) is subjected to high-temperature reduction firing for 9 hours at a firing temperature of 780° C., and is kept for 0.5 hours according to the actual maximum temperature of the water glaze to obtain a finished produ...

Embodiment 2

[0032] 1): Mix the glaze powder of any color with the anti-counterfeit powder according to the ratio of 100:1 to prepare the anti-counterfeit glaze powder;

[0033] 2): In step 1), put the mixed anti-counterfeit glaze powder into a ball mill jar, add 40% water of the total weight, and continue ball milling for more than 24 hours to obtain a water glaze;

[0034] 3): The water glaze obtained in step 2) is filtered with a 200-mesh sieve to obtain a flow rate of 13m / s and a specific gravity of 140g / cm 3 water glaze;

[0035] 4): After the step 3) is completed, immerse the ceramic green body in the water glaze to absorb the glaze for 4 seconds, take it out, and wipe the bottom of the green body clean;

[0036] 5): The glaze blank obtained in step 4) is subjected to high-temperature reduction firing for 10 hours at a firing temperature of 1100° C., and is kept for 1 hour according to the actual maximum temperature of the water glaze to obtain a finished product.

[0037] The prep...

Embodiment 3

[0039] 1): Mix any color glaze powder and anti-counterfeit powder according to the ratio of 100:1.5 to prepare anti-counterfeit glaze powder;

[0040] 2): In step 1), put the mixed anti-counterfeit glaze powder into a ball mill tank, add 50% water of the total weight, and continue ball milling for more than 24 hours to obtain a water glaze;

[0041] 3): The water glaze obtained in step 2) is filtered with a 200-mesh sieve to obtain a flow rate of 15m / s and a specific gravity of 150g / cm 3 water glaze;

[0042] 4): After the step 3) is completed, immerse the ceramic body in the water glaze to absorb the glaze for 5 seconds, take it out, and wipe the bottom of the body;

[0043] 5): The glaze base obtained in step 4) is subjected to high-temperature reduction firing for 12 hours at a firing temperature of 1320° C., and is kept for 1.5 hours according to the actual maximum temperature of the water glaze to obtain a finished product.

[0044] The prepared anti-counterfeiting cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com