Structure capable of improving thermal performance of under-window wall and method for improving thermal performance of under-window wall

A technology of thermal performance and inner wall, applied in building components, building structure, building maintenance, etc., can solve the problems of large heat transfer coefficient of wall and heat loss, etc., to achieve simple and easy construction, energy saving, increase heat The effect of utilization and room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

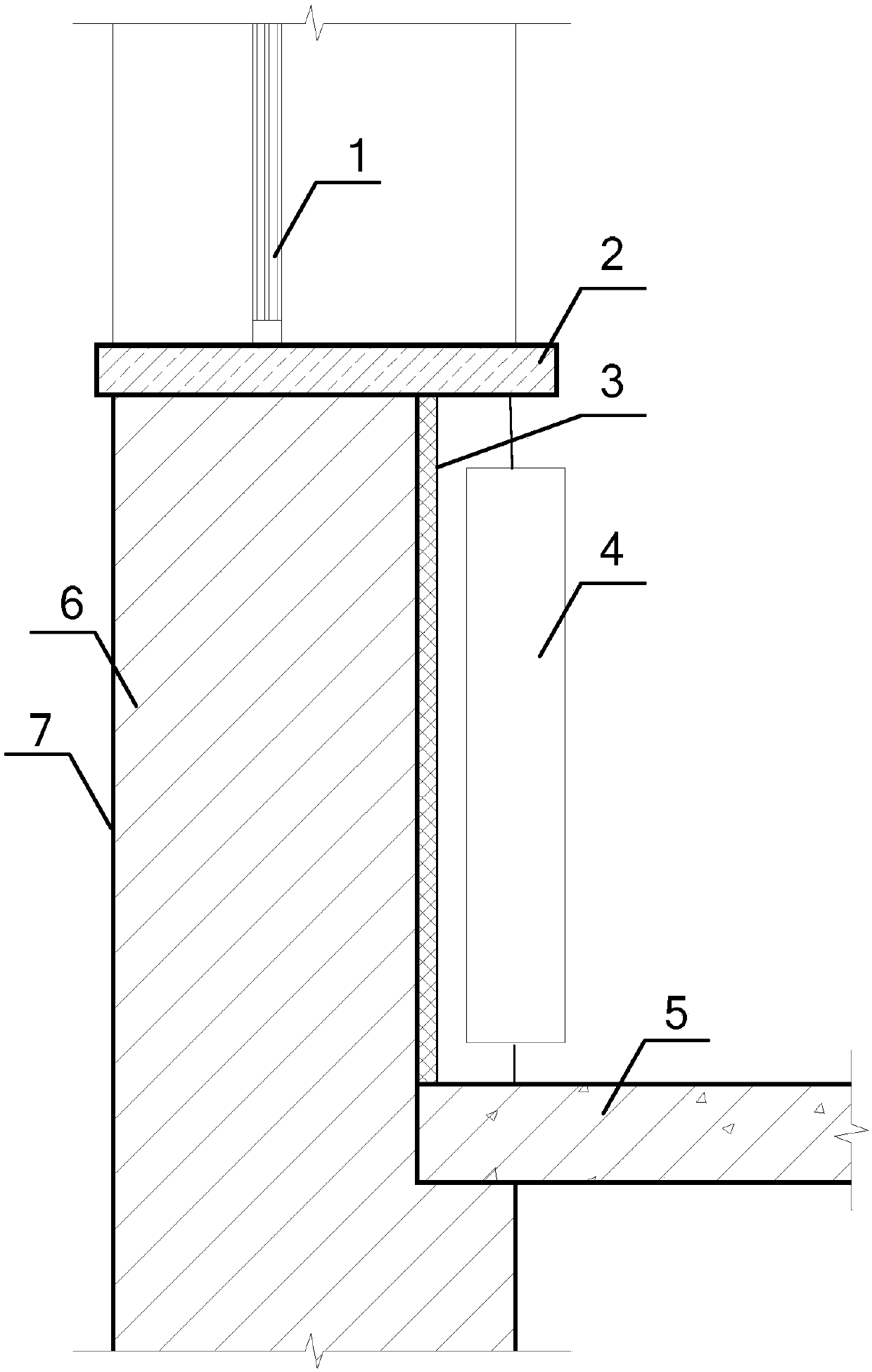

[0016] Specific implementation mode one: refer to figure 1 and figure 2 Describe this embodiment in detail. This embodiment is a structure that can improve the thermal performance of the wall under the window for the purpose of preventing heat from being lost to the outside and at the same time reflecting the heat generated by the radiator to the room. The structure is specifically:

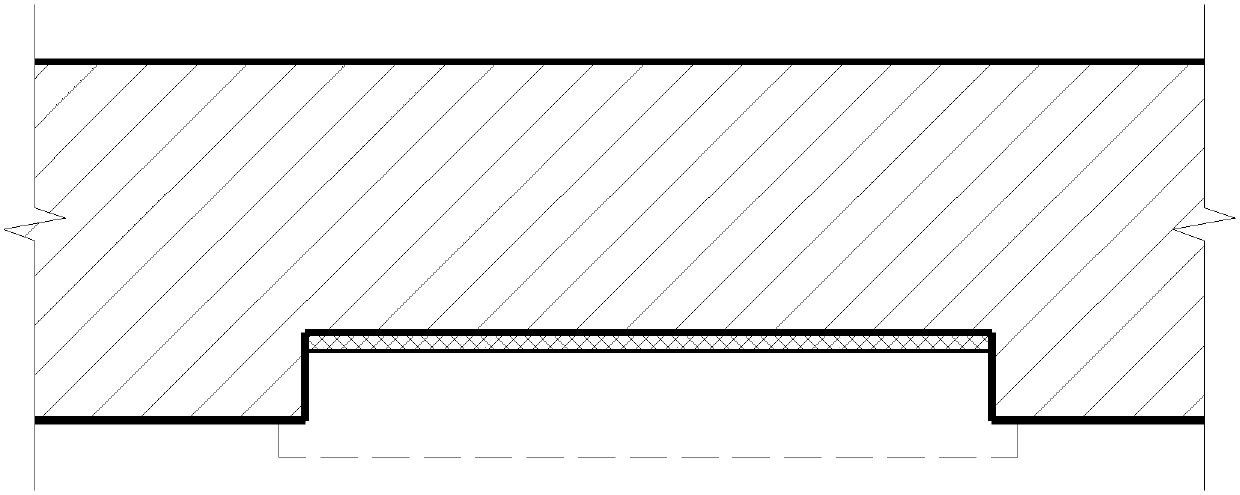

[0017] The wall below the window is in order from outside to inside: exterior finish, 370mm thick solid brick wall, leveling layer, insulation layer, moisture-proof layer and aluminum foil reflection layer, and the layers are pasted and fixed to each other.

[0018] The structure that can improve the thermal performance of the wall under the window described in this embodiment, under the premise of ensuring that the structural form of the existing public building remains unchanged, the part of the wall under the window is treated indoors, and high-efficiency plate insulation materials are added ...

specific Embodiment approach 2

[0019] Specific implementation mode 2: This implementation mode is a method for improving the thermal performance of the wall under the window for the purpose of preventing heat from being lost to the outside and at the same time reflecting the heat generated by the radiator to the room. The specific method is as follows:

[0020] Step 1: In order to ensure the smoothness and firmness of the thermal insulation material, it is necessary to clean and repair the original base wall, remove the dust, loose matter and other substances on the wall that affect the attachment, and then use cement mortar to clean the wall under the window. The inner side is repaired to make the wall level and form a leveling layer.

[0021] Step 2: In order to increase the thermal resistance of the wall under the window, improve the thermal insulation performance of this part, and reduce the loss of indoor heat to the outside. EPS boards (molded polystyrene foam boards), XPS boards (extruded polystyrene...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap