Internal meshing cycloidal gear type hydraulic transformer

An internal meshing, gear-type technology, used in machines/engines, rotary piston pumps, rotary piston machines, etc., can solve the problems of limited hydraulic system design and application, low maximum pressure of hydraulic pumps, large flow pulsation, etc. Light, small flow pulsation, multi-functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

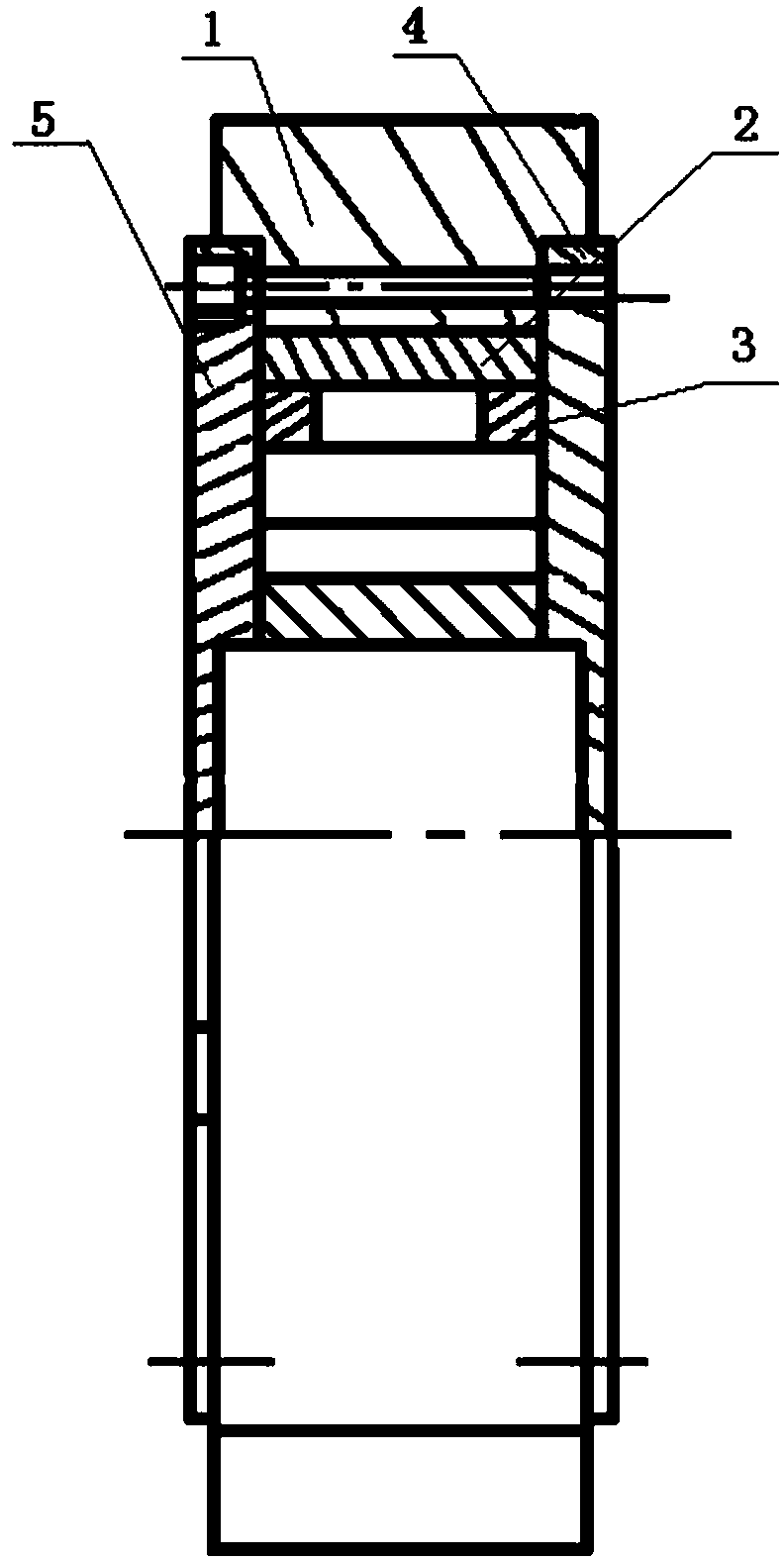

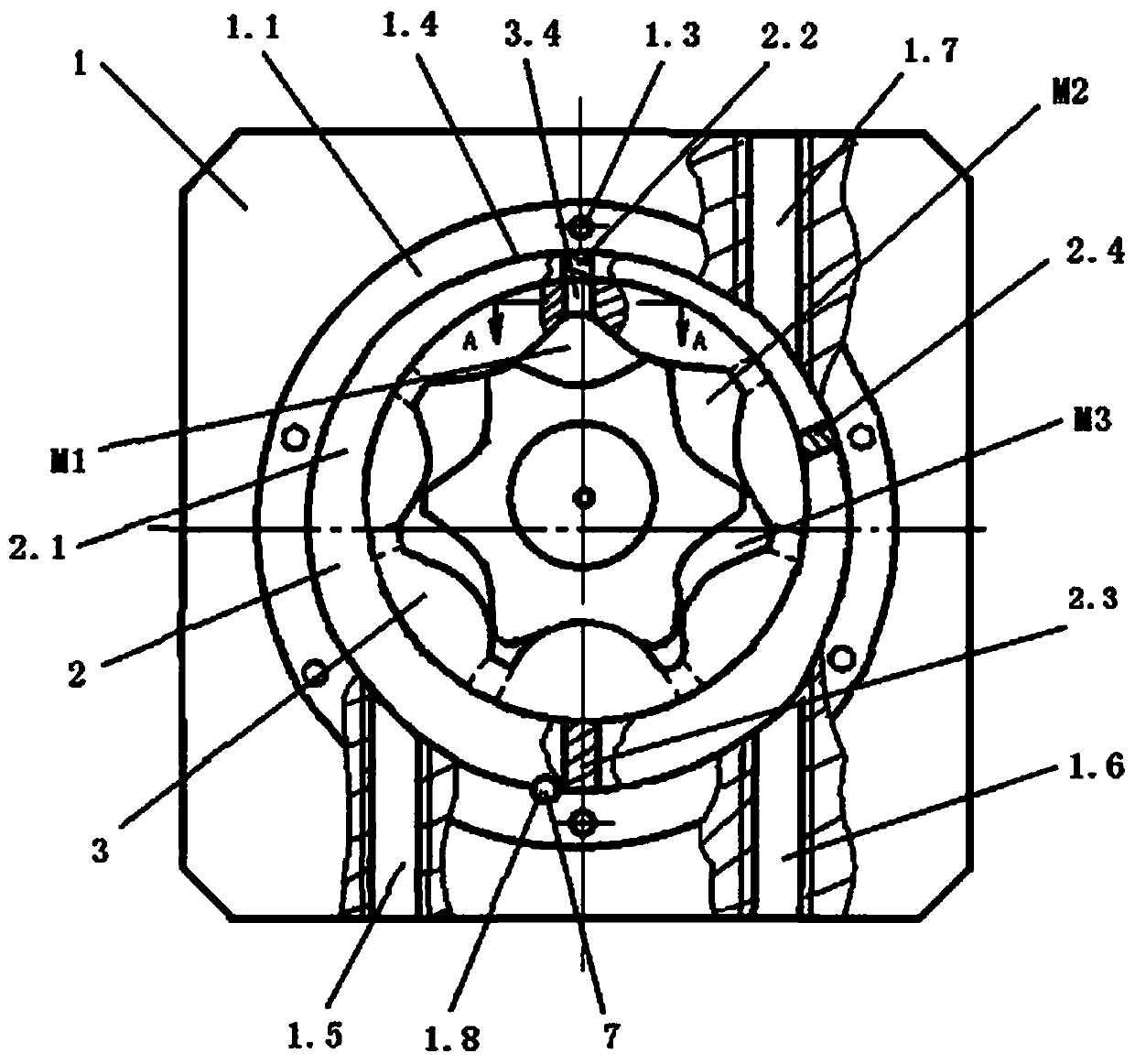

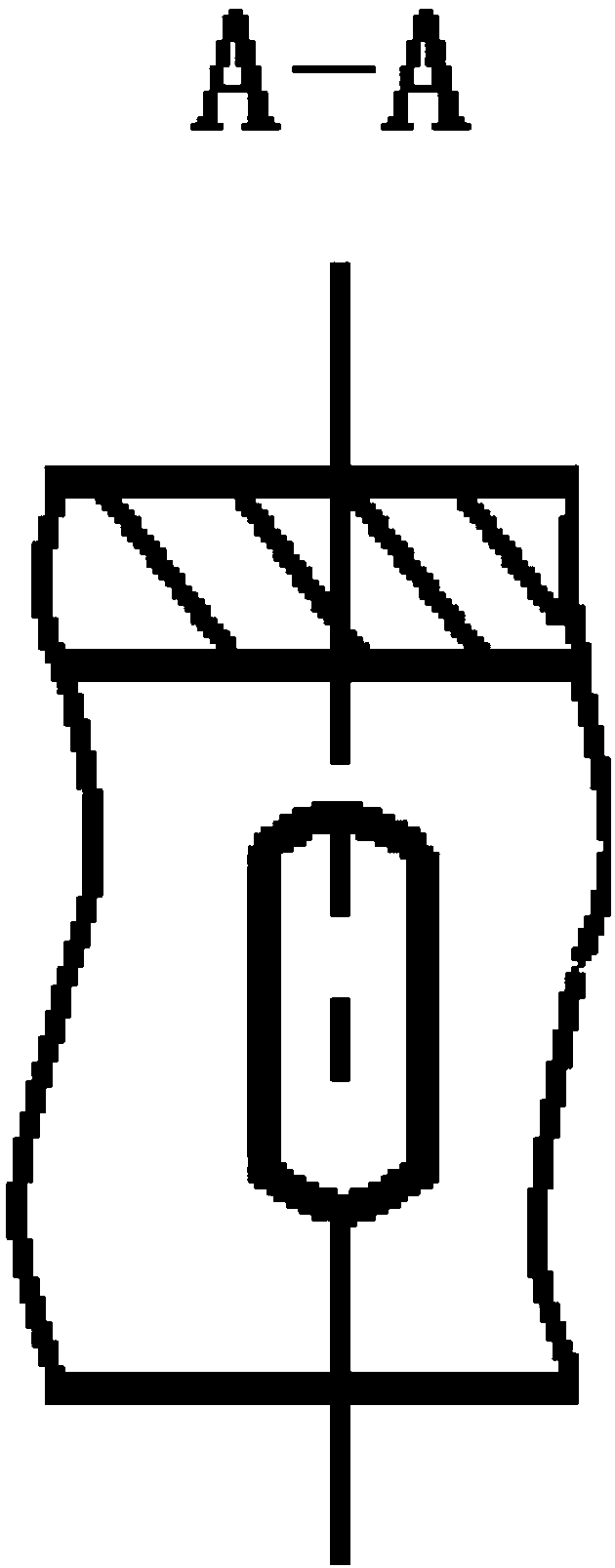

[0028] See figure 1 , figure 2 , image 3 , an internal meshing cycloid gear hydraulic converter, including a housing 1, an eccentric sleeve 2 built in the housing 1, an internal meshing cycloidal rotor pair 3 sleeved in the eccentric sleeve 2, and bolts 6 respectively The upper end cover 4 and the lower end cover 5 connected to both sides of the housing 1; wherein:

[0029] The two ends of the housing 1 are respectively provided with an upper end cover step 1.1 and a lower end cover step 1.2, and mutually connected bolt holes 1.3 are evenly distributed on the two steps, and a set of holes 1.4 is opened in the center of the steps; There are oil inlet 1.5 and pressurized oil port 1.6 on one side, and unloading oil port 1.7 on the opposite side. The three oil ports are connected with the sleeve hole 1.4, and the three oil ports are provided with connecting threads fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com